Temperature differential mine air conditioner cold-heat source energy system

A cold and heat source, temperature difference technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of high emission cost, small cooling capacity, and difficult hydraulic balance, so as to reduce investment and management diameter, saving equipment and a lot of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

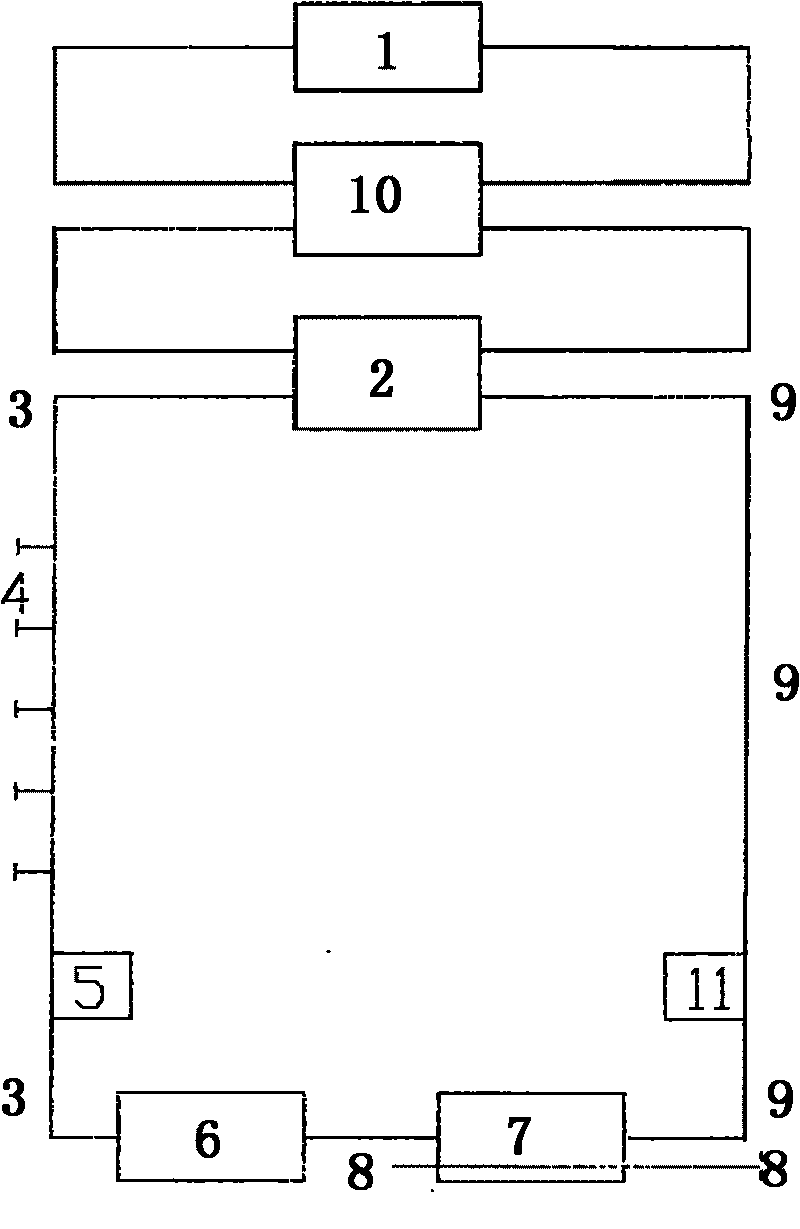

[0034] Such as figure 1 As shown, the temperature difference type mine air-conditioning cold and heat source energy system provided by the present invention includes a fluid medium, a refrigerator device (10), a heat pump central hot water device (1), a low-temperature liquid storage device (6), an evaporator device (7 ), an evaporation-condensation low-temperature heat exchange device (2) and pipeline systems (3), (9) connected to the above-mentioned devices in a closed cycle in sequence, wherein (3) is a high-pressure heat preservation pipeline.

[0035] During operation, open the valve of the low-temperature liquid storage tank (6), and the liquid ammonia enters the evaporator device (7) along the pipeline, and after exchanging cold and heat with the brine from the mine working face after absorbing heat, the liquid ammonia Ammonia is converted into gaseous ammonia; at the same time, the brine in the brine pipeline (8) is transported to the high-temperature working face aft...

Embodiment 2

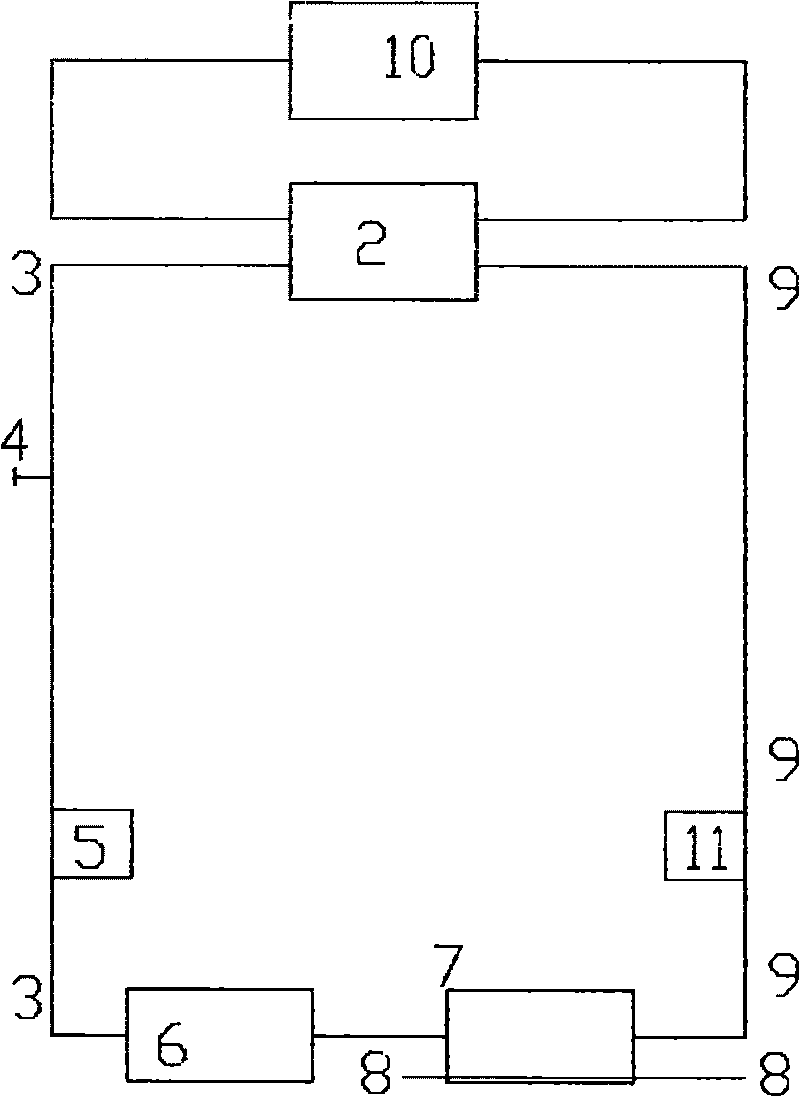

[0037] Such as figure 2 As shown, on the basis of the cycle flow diagram provided in Example 1, the heat pump central hot water device is removed, which simplifies the system flow; when the high-temperature heat in the downhole is transferred to the evaporation-condensation low-temperature heat exchange device (2) In the process, the heat is transferred to the condenser device in the refrigerator by the refrigerator (10), and the heat is directly discharged into the atmosphere by the condensation device of the refrigerator (10), so that the heat in the well can be guaranteed to be absorbed It is continuously discharged from the underground to achieve the goal of eliminating heat damage in high-temperature mines.

Embodiment 3

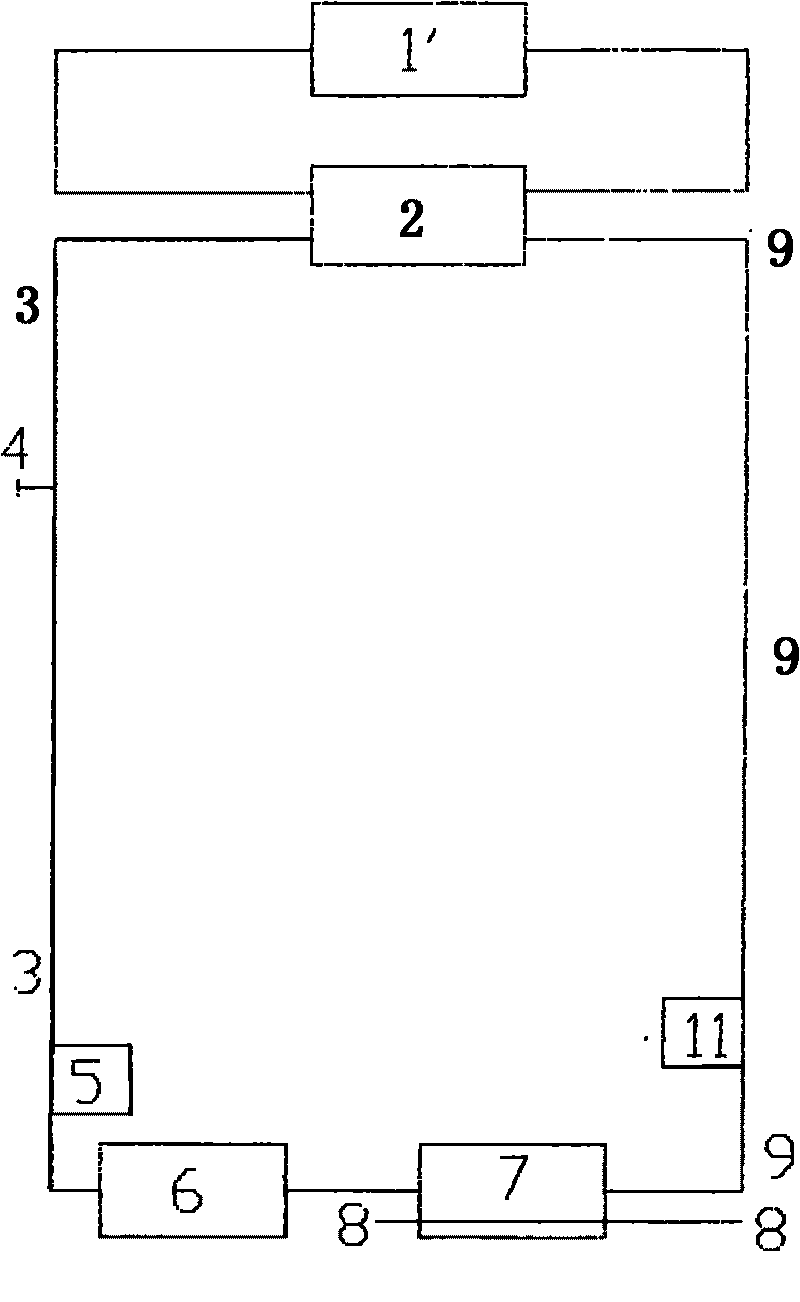

[0039] Such as image 3 As shown, on the basis of the cycle flow diagram provided in Example 1, the refrigerator is removed, and a single cycle process of thermopump heat pump is directly formed by the heat pump central hot water device and the fluid medium ammonia cycle system. When the high temperature heat in the well is is transferred to the evaporation-condensation low-temperature heat exchange device (2), and the heat is directly transferred from the evaporator in the heat pump central heating device (1') to the water storage tank in the heat pump central heating device; if the water storage tank When the hot water is full, the heat from the downhole is directly discharged into the atmosphere by the standby condenser device in the heat pump central hot water device (1'), so that the heat from the downhole can be continuously discharged from the downhole. Achieve the goal of eliminating heat damage in high-temperature mines. In such a cycle, the underground high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com