Optical film and manufacturing method thereof

A technology of optical thin films and layers, applied in optics, optical components, coatings, etc., can solve problems such as increased manufacturing process time, decreased process yield, and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

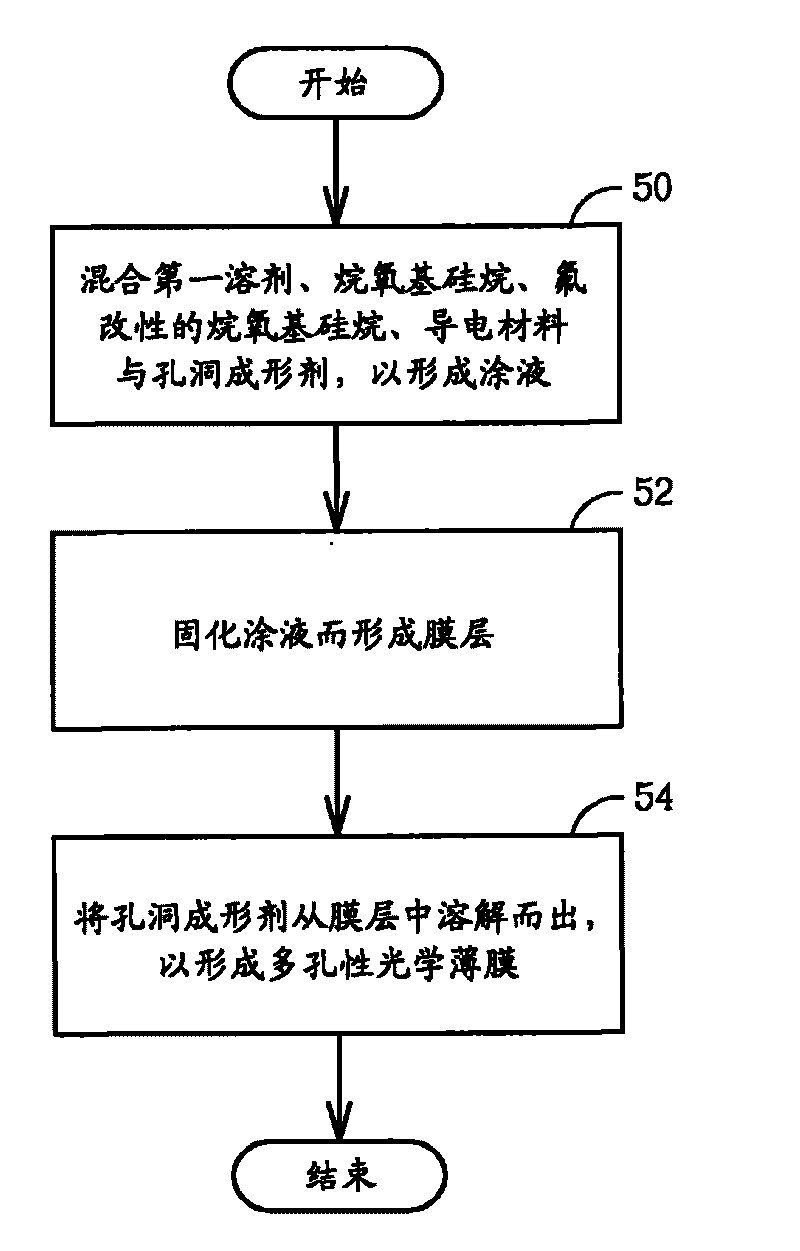

[0043] Please refer to Figure 4 , Figure 4 It is the reaction flow schematic diagram of embodiment 1. First, take about 20.8 grams of tetraethoxysilane (TEOS), about 7 grams of tridecafluoro-1,1,2,2-tetrahydrooctyl-trimethoxysilane, and about 20 grams of isopropanol (IPA) as a reaction solvent. g with 0.1N hydrochloric acid solution (HCl (aq) ) about 7 grams in a reaction bottle, stirred with a stirrer at room temperature for 30 minutes until completely homogeneous, then stopped stirring, and continued to react the homogeneous transparent solution at a reaction temperature of 70°C for 2 hours, and then mixed the solution Bring to room temperature.

[0044] Next, pour about 3 grams of dextrose (D-glucose) aqueous solution (concentration is about 0.8 moles per liter) that has been prepared in advance into the above-mentioned viscous mixed solution and stir vigorously until it is homogeneous, and another about 7 grams The polyaniline aqueous solution (with a solid content o...

Embodiment 2

[0048] The reaction process of embodiment 2 is similar to the reaction process of embodiment 1, but the increment of tridecafluoro-1,1,2,2-tetrahydrooctyl-trimethoxysilane added in embodiment 2 is about 10 grams , and the added polyaniline aqueous solution was reduced to about 5 grams, and after Figure 4 Transparent optical films were produced following the procedure shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com