Rotor-free sensor motor driver and vehicle having same

A sensor and drive technology, applied in the direction of electric vehicles, electronic commutation motor control, motors, etc., can solve the problems of heavy motor load, loud motor noise, strong vehicle vibration, etc., to improve electrical efficiency, increase mileage, and start smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

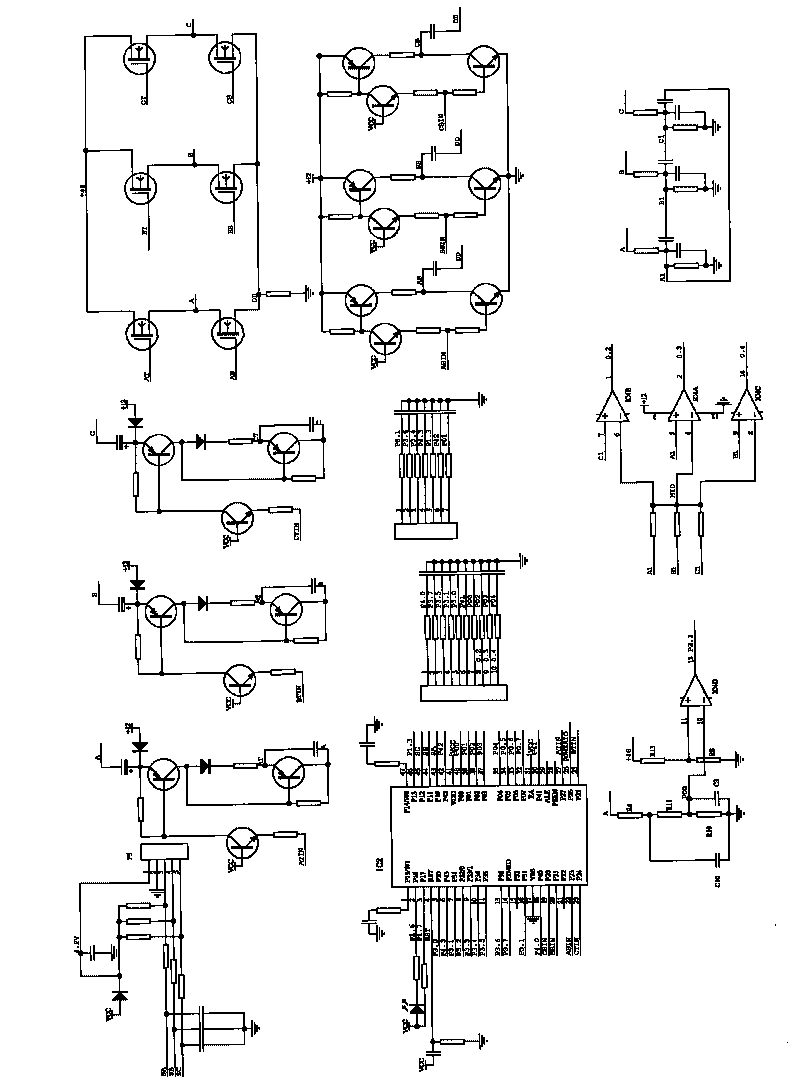

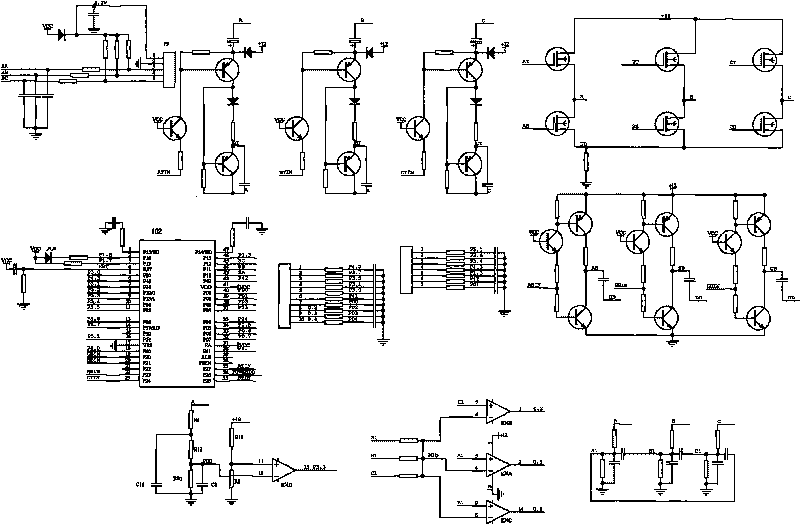

[0012] A driver for a motor without a rotor sensor, comprising a control circuit, a power drive circuit, characterized in that it has a three-phase phase-shifting comparison circuit, a counter electromotive force zero-crossing detection circuit, and the counter electromotive force zero-crossing detection circuit includes a phase line voltage divider circuit, The output of the three-phase shifting comparison circuit is electrically connected to the single-chip electromechanical device in the control circuit, and the counter electromotive force zero-crossing circuit is electrically connected to the single-chip electromechanical device; the counter electromotive force zero-crossing circuit is electrically connected to the single-chip electromechanical device through a comparator , one input of the comparator is connected to the phase line voltage divider circuit, and the other input end of the comparator is connected to the power supply voltage divider circuit; the phase line volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com