Method for carrying out laser-micro-engraving marking anti-counterfeiting identification code on inner surface of transparent or translucent container

A laser internal engraving and translucent technology, which is applied in the field of laser internal engraving marking anti-counterfeiting identification codes, can solve the problems of artificial erasure or abrasion, and achieve the effect of simple and compact structure and fast internal engraving coding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

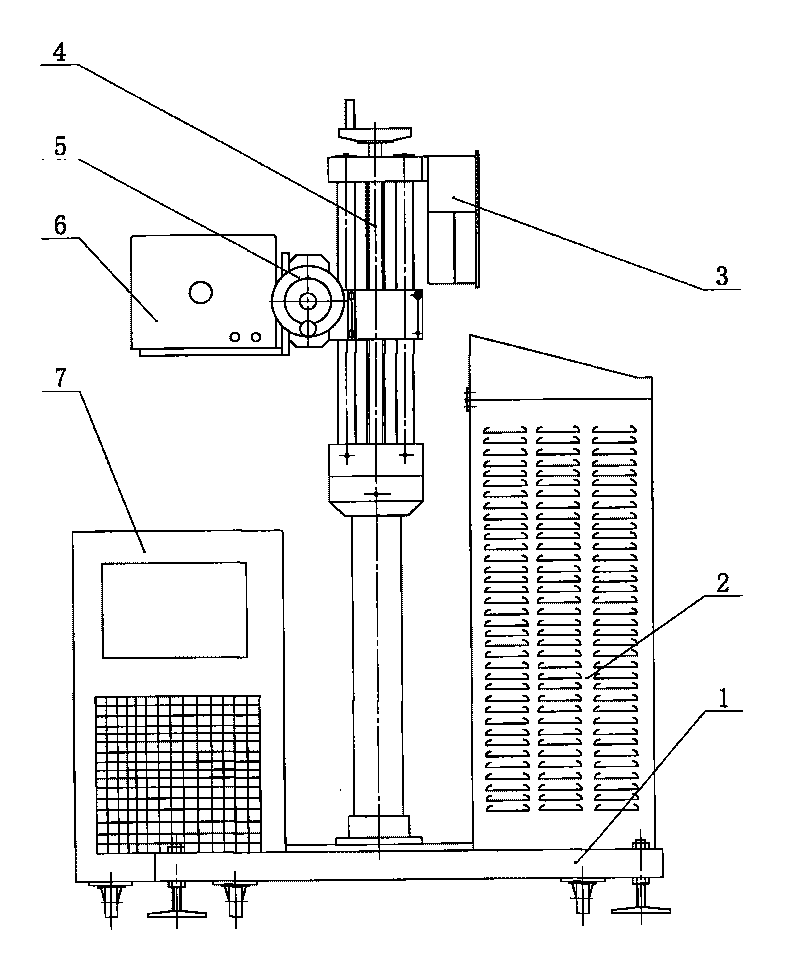

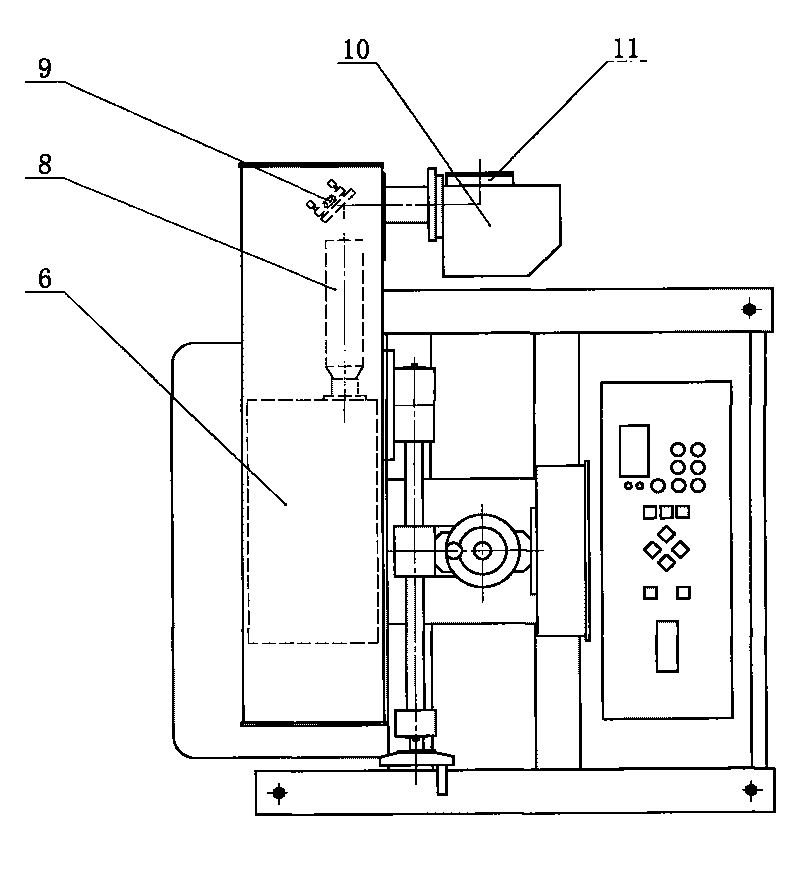

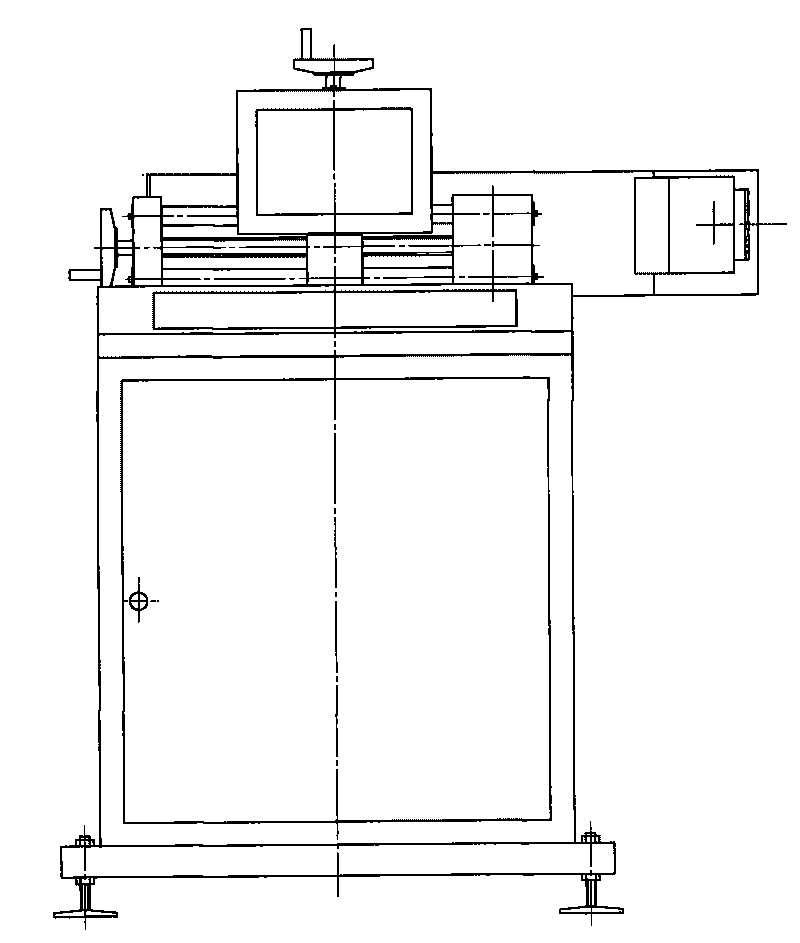

[0021] Such as figure 1 , figure 2 , image 3 As shown, the special laser engraving and marking system for glass wine bottles is composed of a bracket base 1, a laser control system 2, an industrial tablet computer 3, a Z-direction moving mechanism 4, a Y-direction moving mechanism 5, and a 532nm green laser system (water-cooled or air-cooled). ) 6. Water circulation constant temperature system (air-cooled laser does not have this system) 7, beam expander 8, total mirror 9, two-dimensional laser scanning system 10, f-θ focusing mirror 11.

[0022] The laser system of the special laser engraving and marking system for glass wine bottles is composed of a semiconductor end-pumped frequency doubled laser 6, a beam expander 8, a total mirror 9, a two-dimensional scanning galvanometer mechanism 10, and an F-θ focusing mirror 11. . The pumping method of the semiconductor laser is an end pumping method, which is beneficial to the improvement of the laser beam. The semiconductor end-pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com