Method for using solvent type resin aluminum pigment in water paint

A technology of water-based paint and aluminum pigment, which is applied in the application of treated aluminum pigment in water-based paint, the surface treatment of aluminum pigment, and the field of paint, which can solve the problems of high cost and high price of water-based aluminum powder paint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

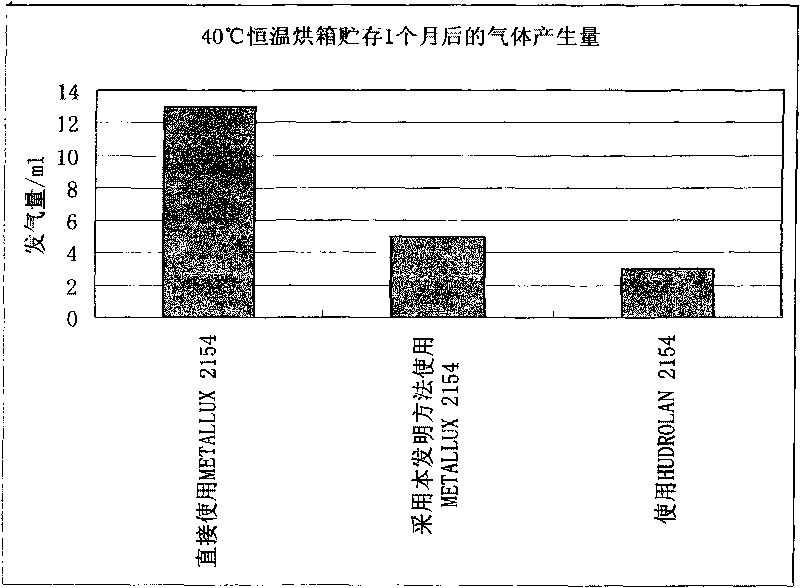

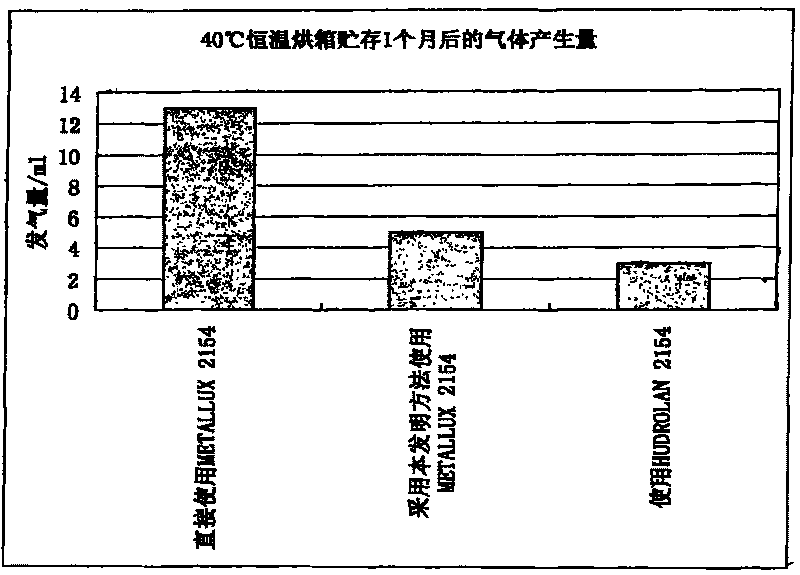

Image

Examples

Embodiment 1

[0041] Aluminum pigment dispersion paste formula:

[0042] Component name Amount (mass%)

[0043] Epoxy Phosphate Resins Containing Phosphate and Hydroxyl Groups 8

[0044] Propylene glycol butyl ether 46.4

[0045] TEGO Dispers 655 (wetting and dispersing agent produced by Degussa) 5

[0046] Dimethylethanolamine 0.6

[0047] Eckart Metallux 2154

[0048] (Aluminum pigments for solvent-based paints produced by AICART) 40

[0049] Put the epoxy phosphate resin, propylene glycol butyl ether, and TEGO Dispers 655 containing phosphate groups and hydroxyl groups into the container according to the above-mentioned dosage, stir until transparent, then add the above-mentioned amount of dimethylethanolamine, at this time the pH value is 7.5, start to add the above amount of Metallux 2154 slowly under the condition of low-speed stirring, until a uniformly dispersed slurry without particles is obtained, stop stirring, and set aside.

[0050] Water-based aluminum powder coating for...

Embodiment 2

[0061] Aluminum pigment dispersion paste formula:

[0062] Component name Amount (mass%)

[0063] Epoxy Phosphate Resins Containing Phosphate and Hydroxyl Groups 10

[0064] Ethylene glycol butyl ether 38.7

[0065] TEGO Dispers 655 (wetting and dispersing agent produced by Degussa Company) 5.5

[0066] Dimethylethanolamine 0.8

[0067] Eckart Metallux 2154 (a solvent-based coating produced by Eckart

[0068] with aluminum pigment) 45

[0069] Water-based aluminum powder coating formula:

[0070] Dosage (mass%)

[0071] Nuplex Setalux6802 (aqueous polyacrylate dispersion produced by Nuplex Company) 42

[0072] Nuplex Setalux6801 (aqueous polyacrylate dispersion produced by Nuplex Company) 25

[0073] Deionized water 18.2

[0074] Dimethylethanolamine 0.3

[0075] BYK011 (defoamer produced by BYK chemical company) 0.5

[0076] BYK347 (substrate wetting agent produced by BYK chemical company) 0.5

[0077] BYK425 (rheolo...

Embodiment 3

[0081] Aluminum pigment dispersion paste formula:

[0082] Component name Amount (mass%)

[0083] Epoxy Phosphate Resins Containing Phosphate and Hydroxyl Groups 8

[0084] Propylene glycol butyl ether 48.9

[0085] TEGO Dispers 655 4.5

[0086] Dimethylethanolamine 0.6

[0087] Eckart Metallux 2154 38

[0088] Water-based aluminum powder coating formula (two-component polyurethane):

[0089] Component name Amount (mass%)

[0090] Bayhydrol A145 (hydroxyl acrylic acid aqueous dispersion produced by Bayer) 65

[0091] Deionized water 14.6

[0092] Dimethylethanolamine 0.3

[0093] BYK011 (defoamer produced by BYK chemical company) 1.0

[0094] BYK345 (substrate wetting agent produced by BYK chemical company) 0.3

[0095] BYK425 (rheological additive produced by BYK Chemical Company) 0.8

[0096] Aluminum pigment dispersion paste 18

[0097] Curing agent Bayer Bayhydur 2547 (produced by Bayer

[0098] water dispersible polyisocyanate) 12

[0099] The preparation pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap