Reactive ink for printing and dyeing and method for carrying out jet printing on denim fabric by adopting same

A technology of active ink and denim fabric, applied in the field of textile printing and dyeing, can solve the problems of the lack of popularization of inkjet printing and the high price of ink, and achieve the effect of fast color, bright color and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

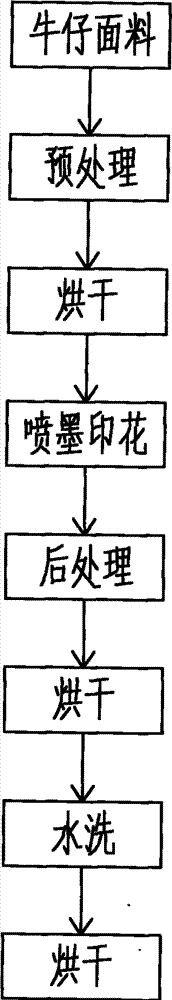

Method used

Image

Examples

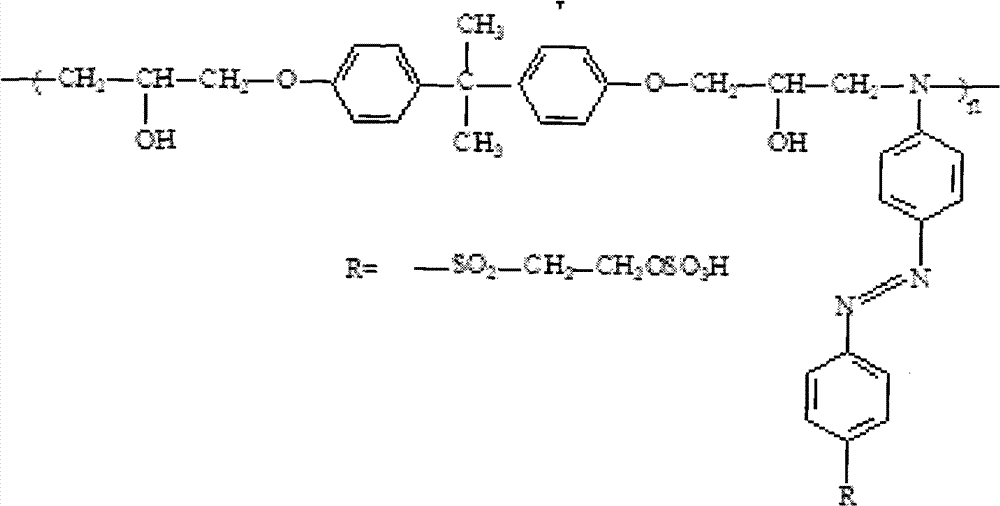

Embodiment 1

[0019] Take a piece of indigo denim and soak it in the solution for enzyme desizing and anti-seepage pretreatment. The function of enzyme desizing is to remove the size on the fabric fibers, which is conducive to better contact and adhesion of dyes to the fibers on the fabric. In conclusion, the role of anti-seepage is to prevent the ink from spreading to the surroundings during printing, resulting in blurred patterns. The technical formula of the solution is to add 4g of amylase, 5g of salt, 1g of sodium alginate, 2g of sodium bicarbonate, and 1.5g of urea per liter of water. Treatment conditions: the temperature is 55°C; then dry at 90°C; in the presence of vinylsulfone type epoxy resin-based polymer reactive dye 5%; surfactant OP-100.6%; humectant PEG 5%; deionized water 89.4%, after preparing according to the above formula, add PH value buffer solution to adjust the PH value to 8, print under the printer of the prepared ink; then through a post-treatment of spraying hot al...

Embodiment 2

[0026] Take a piece of indigo denim and soak it in the solution for enzyme desizing and anti-seepage pretreatment. The technical formula of the solution is to add: 6g of amylase, 7g of salt, 2g of sodium alginate, 5g of sodium bicarbonate, 4g of urea, after preparing according to the above formula, add pH value buffer to adjust the pH value to 6, treatment conditions: temperature is 60°C; then dry at 100°C; Dye 10%; Surfactant OP-100.7%; Humectant PEG 7%; Deionized water 82.3%, after preparing according to the above formula, add pH value buffer solution to adjust the pH value to 8, and print on the printer of the prepared ink; After a post-treatment of spraying hot alkali, the concentration of alkali solution is 15g of alkali per liter of water, and the temperature is 75°C; it is dried at 100°C, washed with water, and then dried at 100°C.

[0027] The technical parameters of denim after inkjet printing are as follows:

[0028] Color fixing rate: 80%

[0029] K / S value: 1.5 ...

Embodiment 3

[0033] Take a piece of indigo denim and soak it in the solution for enzyme desizing and anti-seepage pretreatment. The technical formula of the solution is to add per liter of water: 8g of amylase, 9g of salt, 4g of sodium alginate, 7g of sodium bicarbonate, urea 6g, after preparing according to the above formula, add pH buffer solution to adjust the pH value to 6.5, conditions: the temperature is 65°C; then dry at 110°C; %; Surfactant OP-100.9%; Moisturizing agent PEG 9%; Deionized water 75.1%, after preparing according to the above formula, add pH value buffer solution to adjust the pH value to 8, and print under the printer of the prepared ink; A post-treatment of hot alkali spraying, wherein the concentration of alkali solution is 18g of alkali per liter of water, and the temperature is 78°C; it is dried at 110°C, washed with water, and then dried at 110°C.

[0034] The technical parameters of denim after inkjet printing are as follows:

[0035] Color fixing rate: 87%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com