Aluminum sensor used in hot dip galvanizing process and preparation method thereof

An aluminum sensor and sensor technology, applied in hot dip plating process, metal material coating process, instruments, etc., can solve the problems of poor accuracy, short life, inconvenient use, etc., and achieve improved work performance, simplified preparation, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Press Al 2 (WO 4 ) 3 The stoichiometric ratio weighs the corresponding Al 2 o 3 and WO 3 , the raw material, ZrO 2 Balls and absolute ethanol were mixed according to the mass ratio of 1:2:0.5 and put into a polytetrafluoroethylene ball milling tank. The slurry was obtained after wet ball milling for 10 hours, and the slurry was dried naturally. After the ethanol volatilized, put Calcined in a resistance furnace, the calcined atmosphere is air atmosphere, the calcined temperature is 950°C, after calcined for 12 hours, the temperature is lowered to normal temperature. Add binder PVB (polyvinyl butyral) 1% (percentage by weight, added) to the powder after roasting, wet ball mill it again according to the aforementioned method for 10 hours, and obtain aluminum ion conductor Al after milling and drying in the air. 2 (WO 4 ) 3 Powder.

[0025] Will Al 2 (WO 4 ) 3 The powder is pressed under a pressure of 300MPa to form a disc body with a diameter of 13mm and a thi...

Embodiment 2

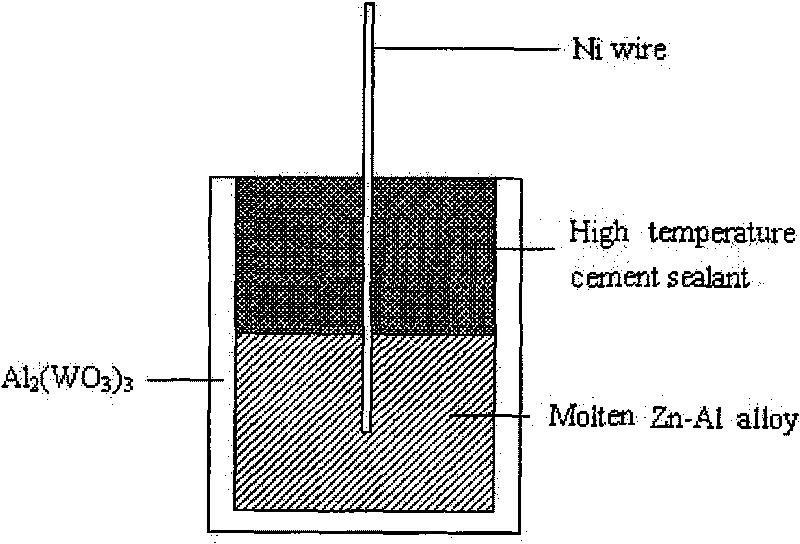

[0027] Dense Aluminum Ion Conductor Al 2 (WO 4 ) 3The preparation method of the tube is the same as Example 1. Put Zn-Al (Al content 5wt%) alloy chip 2g as reference electrode in Al 2 (WO 4 ) 3 In the electrolyte tube, the metal Ni wire as the lead wire is inserted into the bottom of the tube, and finally the tube mouth is sealed with high-temperature cement and dried to obtain an aluminum sensor. The structure of the aluminum sensor is as figure 2 shown.

[0028] At 430-550 ℃, after adding different concentrations of aluminum to the zinc solution, the sensor has good response characteristics. The electromotive force between the aluminum concentration and the sensor at different temperatures conforms to the Nernst relationship.

Embodiment 3

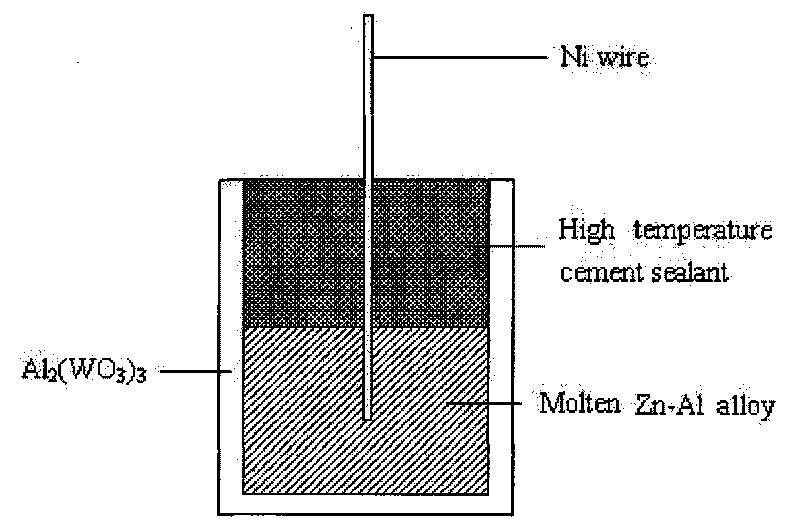

[0030] Dense Aluminum Ion Conductor Al 2 (WO 4 ) 3 The preparation method of the tube is the same as Example 1. in Al 2 (WO 4 ) 3 Add 1.5g of Zn-Al (Al content 0.5wt%) alloy chips into the tube and place it in the electrolyte tube, then insert the metal Ni wire as the lead wire into the bottom of the tube, seal the tube opening with high-temperature cement and dry to obtain an aluminum sensor. At 450-520°C, in the zinc liquid containing different concentrations of aluminum, the experiment is carried out with an aluminum sensor, the sensor responds quickly, and the response time is about 50 seconds. At the same temperature, the aluminum concentration and the electromotive force of the sensor conform to the Nernst relationship. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com