Power module test system and test method thereof

A power module and test system technology, applied in the direction of single semiconductor device testing, etc., can solve problems such as poor flexibility, high test cost, and incomplete assessment of device performance, and achieve the effects of improving comprehensiveness, reducing test cost, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The accompanying drawings show specific embodiments of the present invention, and the present invention will be further described below through the accompanying drawings and the embodiments.

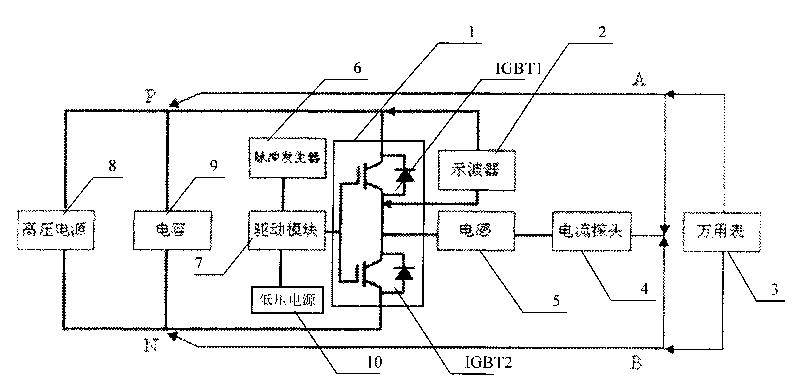

[0032] As a preferred implementation of the power module test system, such as figure 1 The power module test system shown includes:

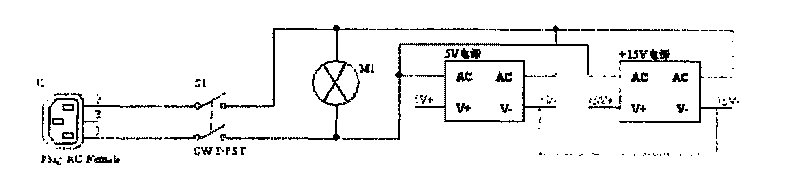

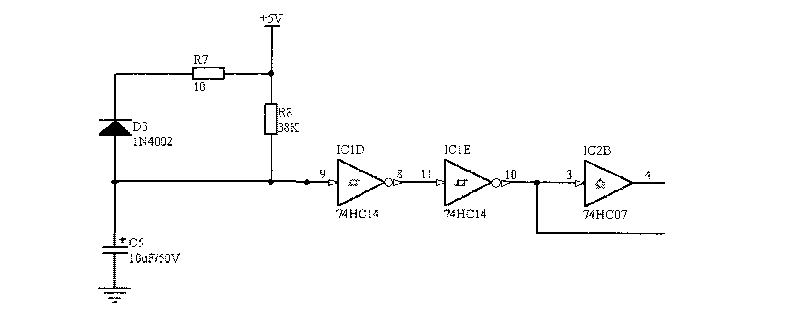

[0033] Oscilloscope 2, multimeter 3, current probe 4, inductor 5, pulse generator 6, drive module 7, high-voltage power supply 8, low-voltage power supply 10, pulse generator 6 generates pulses with variable width, and is amplified by the drive module 7 to control power switching devices The IGBT is turned on and off to control the output voltage and current of the IGBT power module 1, so as to achieve the purpose of evaluating the performance of the power device. The low-voltage power supply 10 provides a 5V power supply to the pulse generator 6 and a 5V, ±15V power supply to the drive module 7 . The high voltage power supply 8 is used to charge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com