Double-layer or multi-layer shivering acetate fiber glasses slab rubber and preparation process thereof

A technology of acetate fiber and rubber sheet, applied in glasses/goggles, optics, instruments, etc., can solve problems such as difficult to meet, no three-dimensional effect, single design and color, etc., and achieve the effect of easy operation, various designs and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

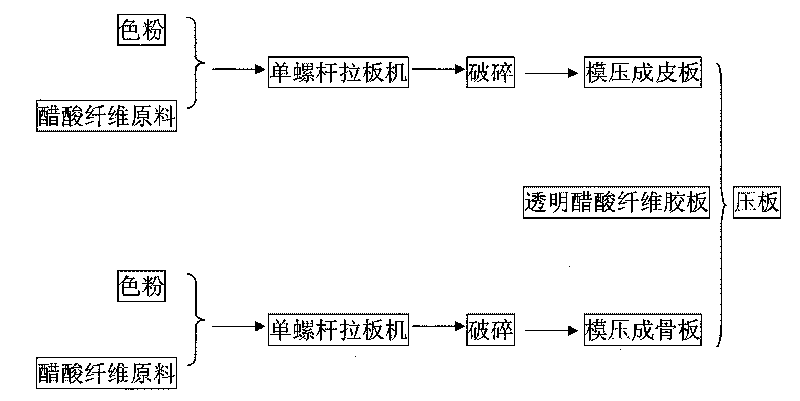

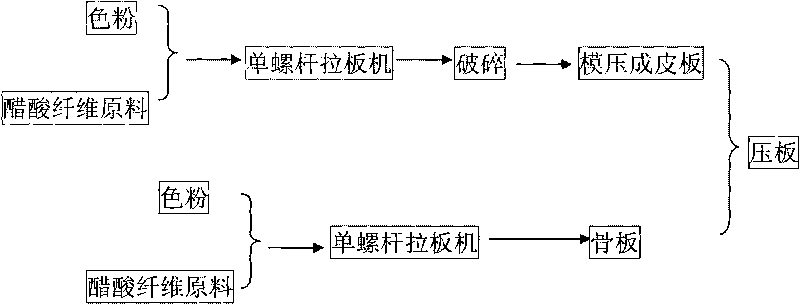

[0033] A kind of preparation method of double, multi-layer floral acetate fiberglass plastic plate, comprises the following steps:

[0034] (1) Preparation of skin board:

[0035] A: Prepare brown toner and add it to the raw material of cellulose acetate, stir evenly, and then use a single-screw drawing machine to prepare the raw material of cellulose acetate with single-color toner into a brown rubber sheet;

[0036] B: Break the brown rubber sheet into 100-mesh irregular brown rubber particles in a crusher;

[0037] C: Put the brown rubber particles into the molding machine, and mold them into a brown leather board;

[0038] (2) Preparation of bone plate:

[0039] A: Prepare black toner and add it to the cellulose acetate raw material, stir evenly, and then use a single-screw drawing machine to prepare the cellulose acetate raw material with monochromatic toner into a black rubber sheet, which is the bone plate;

[0040] (3) Molded board: put the above-mentioned brown ski...

Embodiment 2

[0042] A kind of preparation method of double, multi-layer floral acetate fiberglass plastic plate, comprises the following steps:

[0043] (1) Preparation of skin board:

[0044] A: Prepare yellow toner and add it to the cellulose acetate raw material, stir evenly, and then use a single-screw drawing machine to prepare the cellulose acetate raw material with yellow toner into a yellow rubber sheet;

[0045] B: Crumble the yellow rubber sheet into 120-mesh irregular yellow rubber particles in a crusher; at the same time, use the same method as above to prepare brown rubber particles.

[0046] C: Put the yellow rubber particles and brown rubber particles into the molding machine, and mold them into leather plates with intervals of yellow and brown;

[0047] (2) Preparation of bone plate:

[0048] A: Prepare black toner and add it to the cellulose acetate raw material, stir evenly, and then use a single-screw drawing machine to prepare the cellulose acetate raw material with m...

Embodiment 3

[0051] A kind of preparation method of double, multi-layer floral acetate fiberglass plastic plate, comprises the following steps:

[0052] (1) Preparation of skin board:

[0053] A: Prepare yellow toner and add it to the cellulose acetate raw material, stir evenly, and then use a single-screw drawing machine to prepare the cellulose acetate raw material with yellow toner into a yellow rubber sheet;

[0054] B: Crumble the yellow rubber sheet into 200-mesh irregular yellow rubber particles in a crusher; at the same time, use the same method as above to prepare brown rubber particles.

[0055] C: Put the yellow rubber particles and brown rubber particles into the molding machine, and mold them into leather plates with intervals of yellow and brown;

[0056] (2) Preparation of bone plate:

[0057] A: Prepare black toner and add it to the cellulose acetate raw material, stir evenly, and then use a single-screw drawing machine to prepare the cellulose acetate raw material with m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com