Liquid dairy product containing oligomate and dietary fiber and preparation method thereof

A technology of galactooligosaccharides and dietary fiber, applied in dairy products, milk preparations, applications, etc., can solve problems such as application restrictions of galactooligosaccharides and affecting the stable system of dairy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

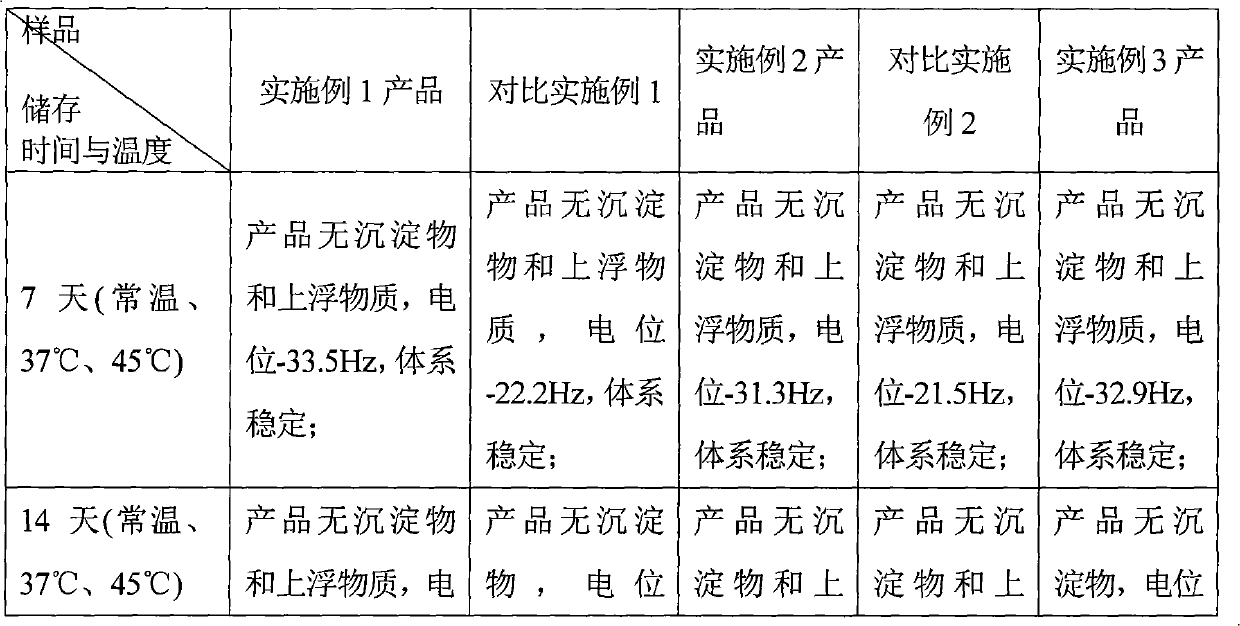

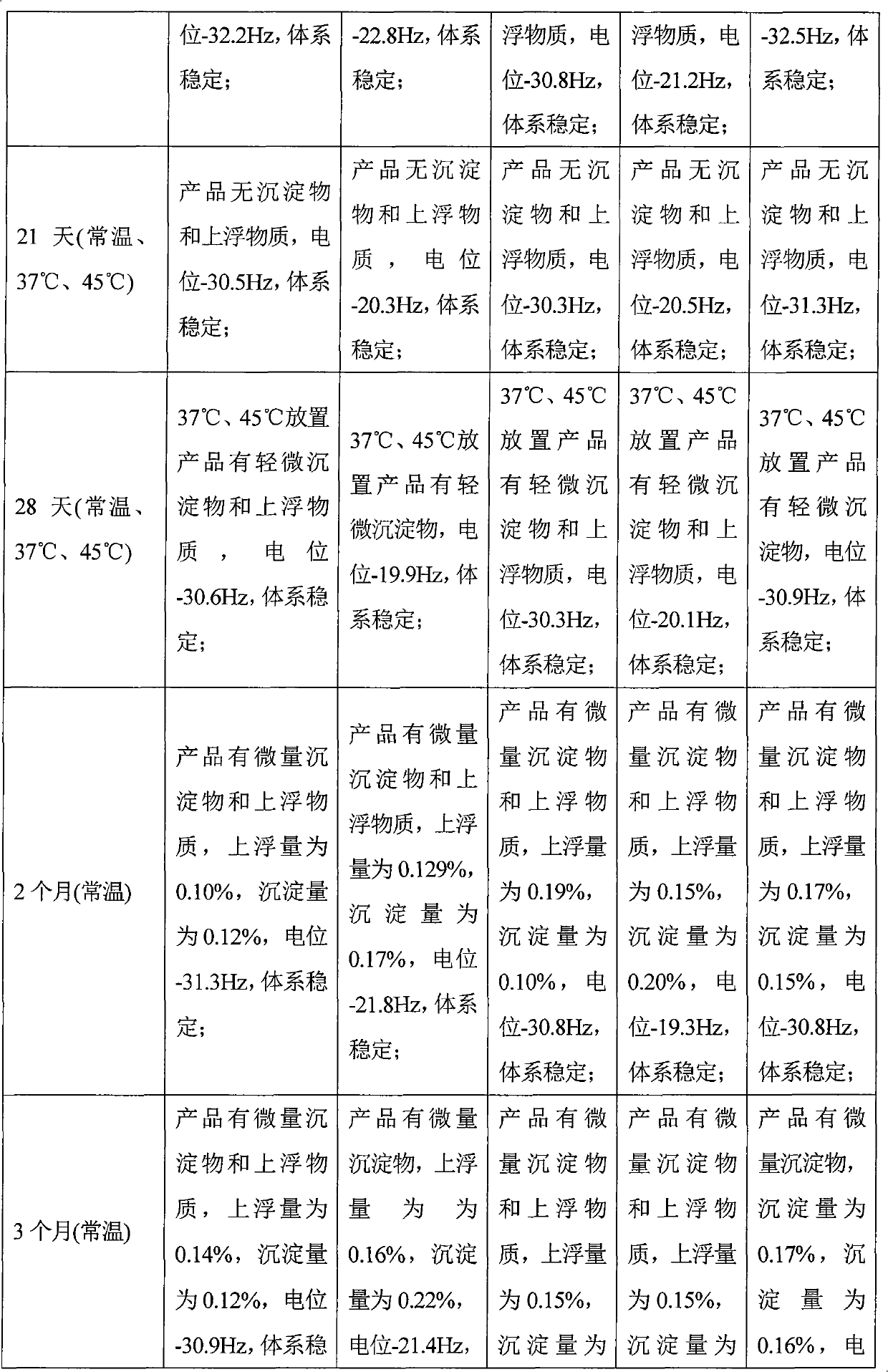

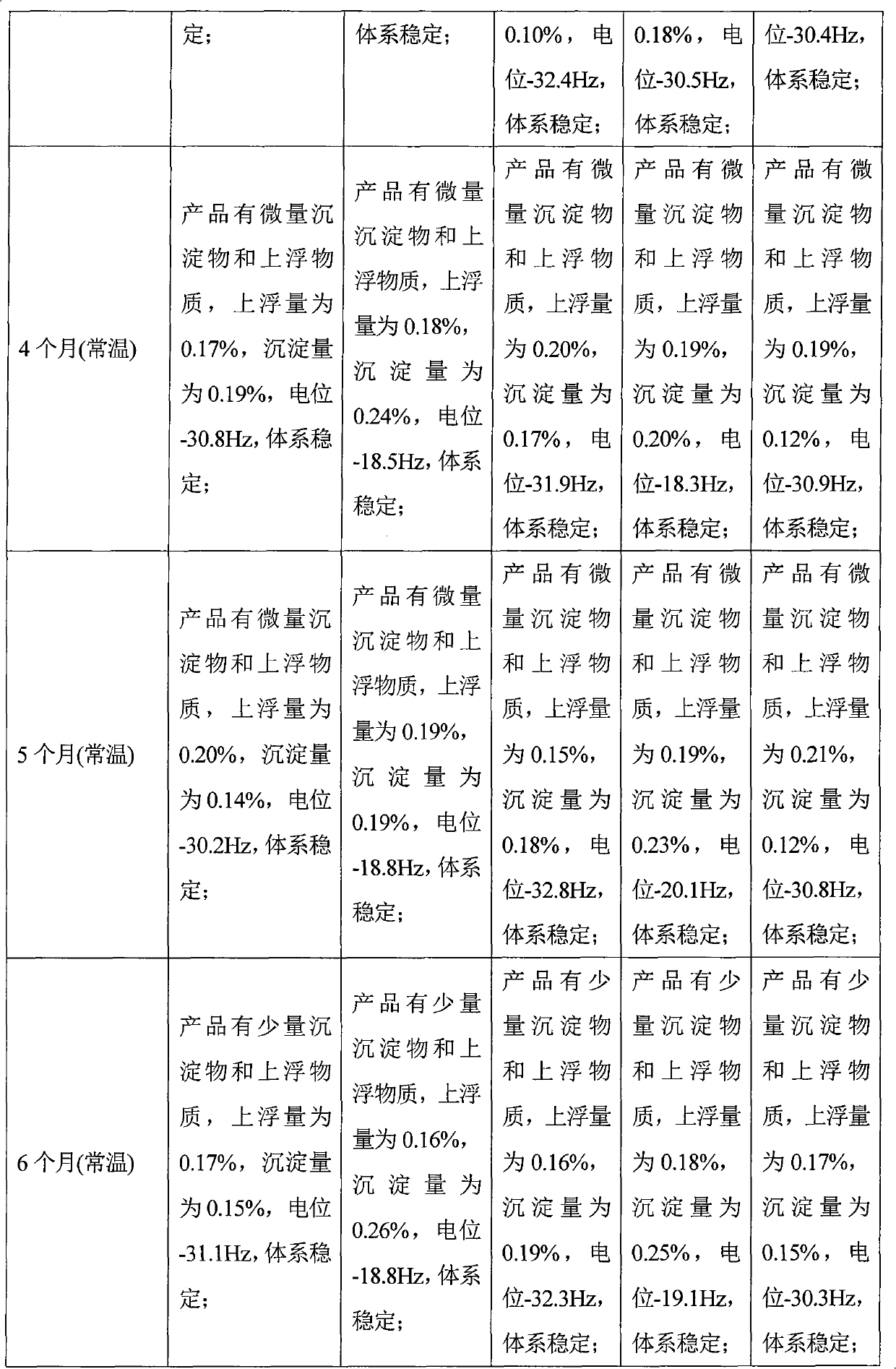

Examples

Embodiment 1

[0024] A raw material formula of a kind of liquid milk of the present embodiment is (100 parts by weight):

[0025] Low-fat milk 94.62 parts

[0026] Galacto-oligosaccharide buffer salt system 0.1 part (effective content 0.04 part)

[0027] Microcrystalline cellulose 0.15 parts

[0028] Carrageenan 0.0135 parts

[0029] Mono-diglyceride 0.12 parts

[0030] Inulin 5 parts

[0031] Among them, 0.1 part of galacto-oligosaccharide, potassium citrate and 2 parts of ingredients are prepared with water to prepare a potassium citrate buffer salt system, and its pH is 7.2.

[0032] Production methods mainly include:

[0033] 1) Pasteurize milk (fresh raw milk can be centrifuged and standardized according to conventional operations to prepare low-fat milk): pasteurize at 80-90°C for 15 seconds; cool to 1-15°C for later use;

[0034] 2) Ingredients: 30% to 35% of the total amount of milk in the formula is slowly added to the milk with high-speed shear stirring (about 1600 rpm) and ...

Embodiment 2

[0039] Embodiment 2, prepare flavored milk

[0040] The raw material formula of the flavored milk of the present embodiment is (100 parts by weight):

[0041] 80 servings of milk

[0042] 2.5 parts of galacto-oligosaccharide buffered saline solution (effective content 1.07 parts)

[0043] Inulin 4.5 parts

[0044] Microcrystalline cellulose 0.11 parts

[0045] Mono-diglyceride 0.08 parts

[0046] Carrageenan 0.012 parts

[0047] The balance is water.

[0048] Among them, 2.5 parts of galacto-oligosaccharides, potassium citrate and 8 parts of ingredients are prepared with water to prepare potassium citrate buffer solution, the pH of which is 7.2.

[0049] Production methods mainly include:

[0050] 1) Pasteurize milk (fresh raw milk can be centrifuged and standardized according to conventional operations to prepare low-fat milk): pasteurize at 80-90°C for 15 seconds; cool to 1-15°C for later use;

[0051] 2) Ingredients: Add functional ingredients (galacto-oligosacchari...

Embodiment 3

[0056] Embodiment 3, prepare flavored milk drink

[0057] The raw material formula of a kind of flavored milk beverage of the present embodiment is (weight part):

[0058] 30 servings of milk

[0059] White sugar 4.0 parts

[0060] 7.5 parts of galacto-oligosaccharide buffer solution (3.2 parts of effective content)

[0061] Inulin 0.1 parts

[0062] Sodium carboxymethyl cellulose 0.40 parts

[0063] Malic acid 0.15 parts

[0064] 0.1 parts of citric acid

[0065] Mono-diglyceride 0.10 parts

[0066] Add water to 100%;

[0067] Among them, 7.5 parts of galacto-oligosaccharides were formulated into sodium citrate buffer solution, the pH of which was 7.5.

[0068] The product preparation method is as follows: a kind of liquid milk production method of the present embodiment mainly comprises:

[0069] 1) Pasteurize milk (fresh raw milk can be centrifuged and standardized according to conventional operations to prepare low-fat milk): pasteurize at 80-90°C for 15 seconds; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com