Catalyst for preparing paraxylene by methyl alcohol conversion, preparation method thereof and application

A technology for methanol conversion and p-xylene, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low market value and complex products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, Zn-HZSM-5 zeolite molecular sieve

[0032] 1) ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =61, Fushun Catalyst Factory) was roasted at 550°C to remove the template agent, exchanged 4 times with 0.5 molar equivalent ammonium nitrate solution in a water bath at 80°C, dried in air at 120°C after the exchange, and roasted at 550°C for 3 hours. Obtain HZSM-5 zeolite molecular sieve.

[0033] 2) get step 1) HZSM-5 zeolite molecular sieve 50g prepared, use 10wt% concentration Zn(NO 3 ) 2 The aqueous solution was immersed for 6 hours, dried, and then calcined at 550° C. for 3 hours to obtain a Zn-HZSM-5 zeolite molecular sieve, wherein the Zn loading amount was 3 wt%.

Embodiment 2

[0034] Embodiment 2, Fe-HZSM-5 zeolite molecular sieve

[0035] 1) ZSM-5 zeolite molecular sieve raw powder (SiO 2 / Al 2 o 3 =61, Fushun Catalyst Factory) was roasted at 550°C to remove the template agent, exchanged 4 times with 0.5 molar equivalent ammonium nitrate solution in a water bath at 80°C, dried in air at 120°C after the exchange, and roasted at 550°C for 3 hours. Obtain HZSM-5 zeolite molecular sieve.

[0036] 2) get step 1) HZSM-5 zeolite molecular sieve 50g prepared, use 10wt% concentration Fe(NO 3 ) 3 The aqueous solution was immersed for 10 hours, dried, and then calcined at 550° C. for 3 hours to obtain Fe-HZSM-5 zeolite molecular sieve, wherein the Fe loading amount was 5 wt%.

Embodiment 3

[0037] Embodiment 3, preparation catalyst

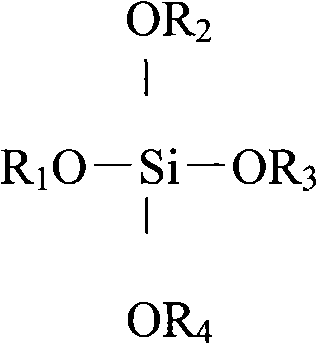

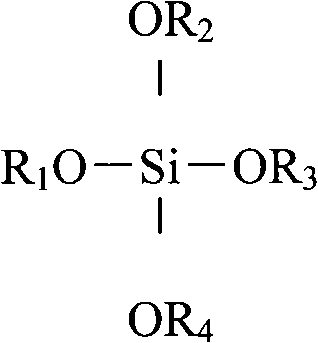

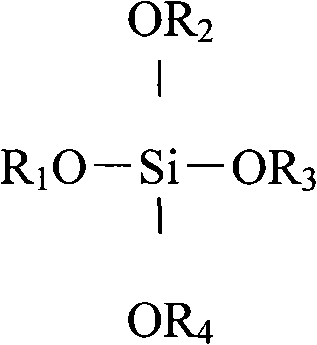

[0038] Zn-HZSM-5, Fe-HZSM-5 zeolite molecular sieves obtained in embodiment 1 and embodiment 2 are carried out surface modification using siloxane reagent tetraethyl silicate:

[0039](1) Immerse 10 grams of Zn-HZSM-5 in 20 grams of tetraethyl silicate for 5 hours, pour out the liquid, dry at 120°C, and bake at 550°C for 3 hours to obtain modified Zn-HZSM -5 catalyst, wherein, the mass content of Zn is 2.9%, and the loading amount of tetraethyl silicate calculated as silicon is 4.3% of the total mass of the catalyst. The number is MTAC-01;

[0040] (2) Put 10 grams of Fe-HZSM-5 into 20 grams of tetraethyl silicate and immerse it for 8 hours, pour out the liquid, dry it at 120°C, and bake it at 550°C for 3 hours to obtain the modified Fe-HZSM -5 catalyst, numbered MTAC-02; wherein, the mass content of Fe is 4.8%, and the loading amount of tetraethyl silicate calculated as silicon is 4.6% of the total mass of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com