Coating preparing method and device by mixing metal and plastic powders

A technology of metal powder and powder, which is applied in the field of preparation of metal composite coatings, and achieves the effect of low cost, high efficiency and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

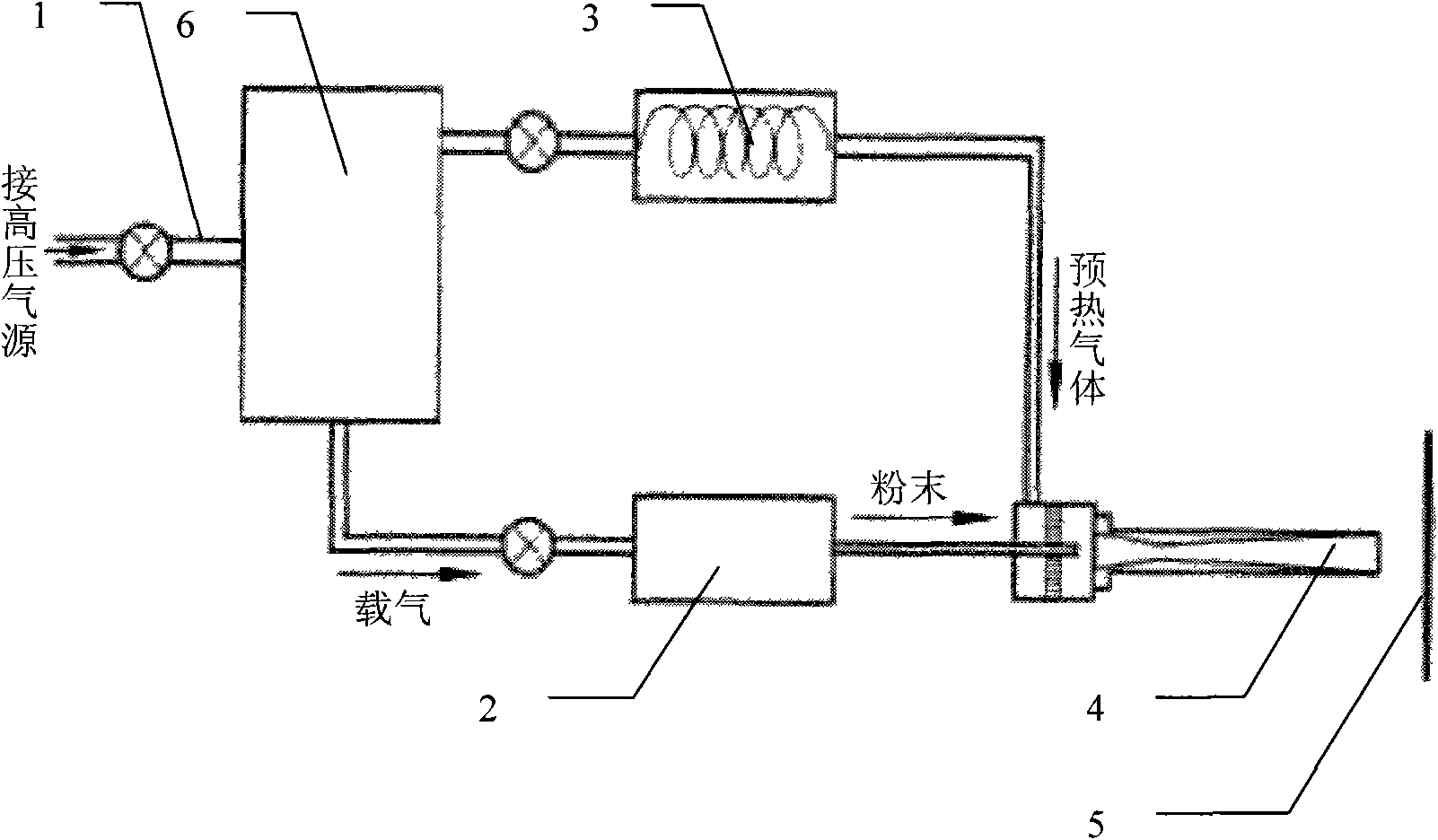

Method used

Image

Examples

Embodiment 1

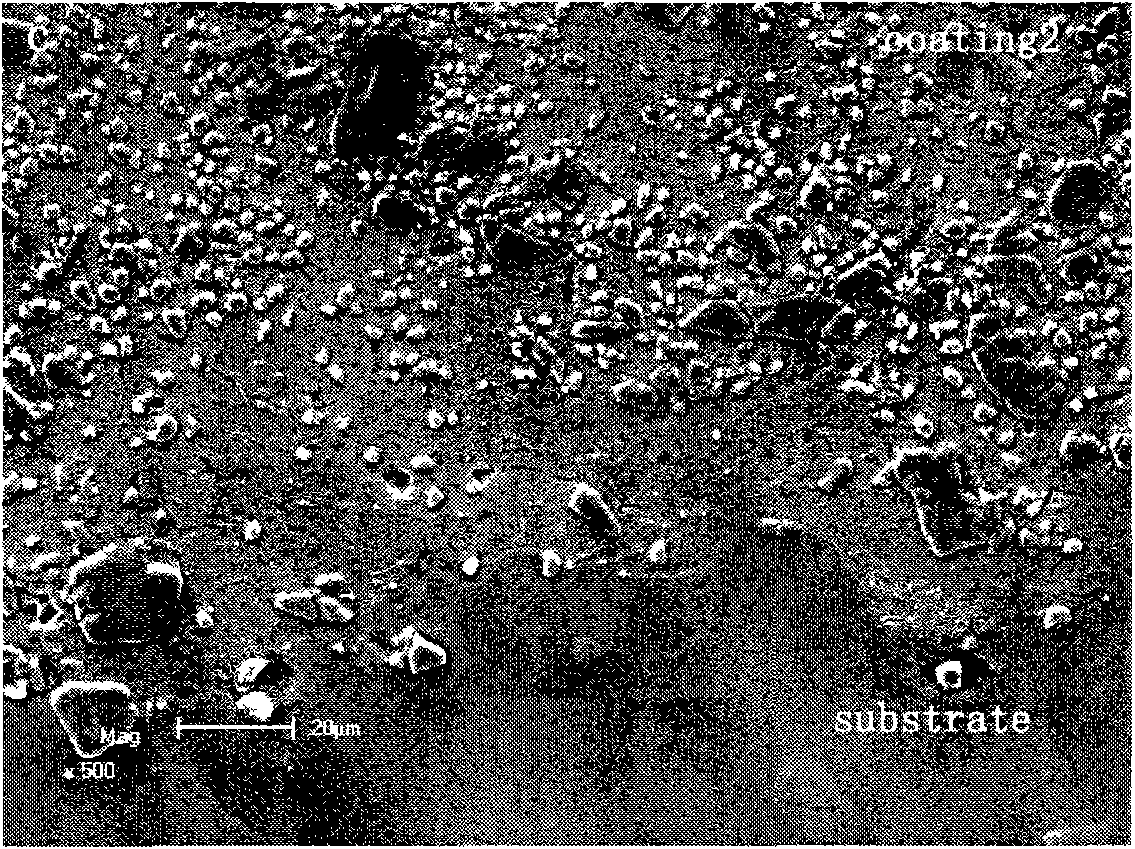

[0027] The metal and plastic powders prepared in this example are used to prepare the composite coating as the anti-corrosion coating Al-PTFE system, the powder used is the mixed powder of Al and PTFE, the weight ratio of Al and PTFE is 3:1, the base material For aluminum alloy. The spraying process parameters are as follows: spraying distance 40mm; gas pressure 1.8MPa; among the two compressed gases, the temperature of the gas entering the powder feeder is room temperature, and the temperature of the gas entering the heater after heating is 200°C; the flow rate of the two compressed gases is 30g / s; the average particle size of metal or plastic powder is 5 microns. As a result, the Al-polytetrafluoro coating was obtained. Through scanning electron microscope observation, the Al-polytetrafluoro two-phase distribution is uniform, and no segregation phenomenon occurs. See figure 2 .

Embodiment 2

[0029] The difference from Example 1 is:

[0030] The metal and plastic composite coating prepared in this example is a seal coating Pb-polyphenylene sulfide powder system, No. 45 steel is used as the substrate, and the coating materials used are Pb and polyphenylene sulfide powder, Pb and polyphenylene sulfide The weight ratio of the powder is 2:1, and the spraying process parameters are as follows: spraying distance 20mm; gas pressure 2.0MPa; among the two compressed gases, the temperature of the gas entering the powder feeder is room temperature, and the temperature of the gas entering the heater after heating is 180°C; The flow rate of the two compressed gases is 30g / s; the average particle size of the metal or plastic powder is 50 microns. As a result, Pb and polyphenylene sulfide coatings were obtained. The two-phase distribution of Pb and polyphenylene sulfide coatings was observed by scanning electron microscope, and the structure was compact.

Embodiment 3

[0032] The difference from Example 1 is:

[0033] The metal and plastic composite coating prepared in this embodiment is a seal coating Sn-polyimide system, and the powder used is a mixed powder of pure aluminum and polyimide, and the weight ratio of pure aluminum and polyimide is 10 : 1, the base material is copper alloy. The spraying process parameters are as follows: spraying distance 10mm; gas pressure 1.9MPa; among the two compressed gases, the temperature of the gas entering the powder feeder is room temperature, and the temperature of the gas entering the heater after heating is 240°C; the flow rate of the two compressed gases is 15g / s; the particle size of metal or plastic powder is 5-50 microns. As a result, the Sn-polyimide coating was obtained. The Sn-polyimide two-phase distribution was uniform and no segregation phenomenon was observed by scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com