Dealcoholized organosilicon sealant with damp-heat resistance and stable storage

A storage-stable, dealcoholized technology, applied in the field of dealcoholized silicone sealant and its preparation, can solve the problems of high toxicity of organotin catalysts, poor processability, and difficult to control dosage, and improve storage performance and process performance. , Excellent damp and heat resistance, good damp and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In terms of parts by weight, 1000g of α, ω-dihydroxy polydimethylsiloxane with a molecular weight of 50,000, 500g of stearic acid-treated nano-calcium carbonate, and 500g of silicon micropowder were vacuum stirred and dehydrated at 100°C for 2 hours as a base. Material use. Take 1000g of the base material, add 30g of methyltrimethoxysilane and 20g of phenyltrimethoxysilane, stir in vacuum for 20 minutes, add 30g of white carbon black and 200g of dimethyl silicone oil with a molecular weight of 500, stir evenly and add 30g of catalyst two (Isopropoxy)bis(ethyl acetoacetate)titanium and 3g of γ-aminopropyltriethoxysilane were stirred in vacuum for 20 minutes, and then discharged and sealed for storage.

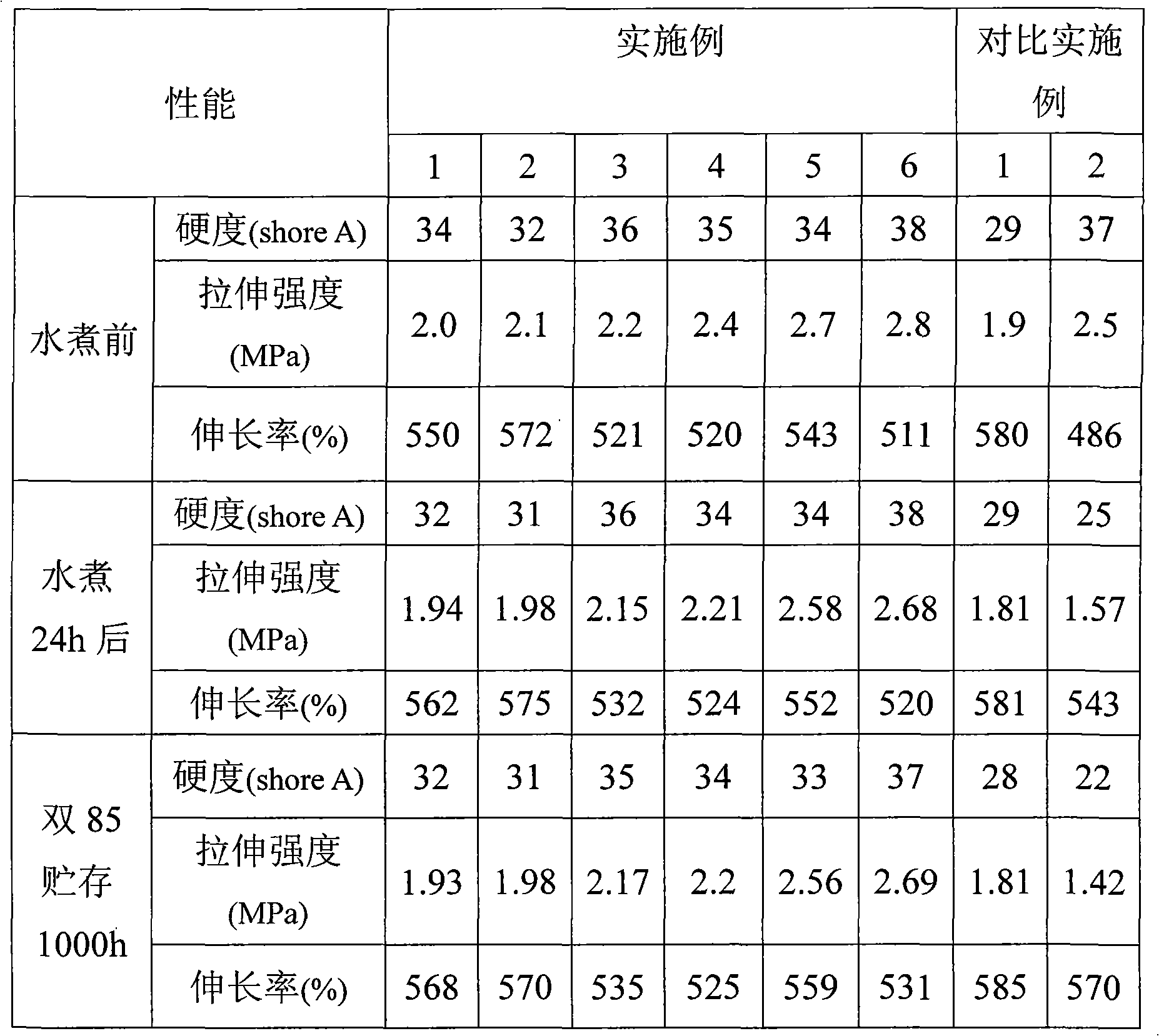

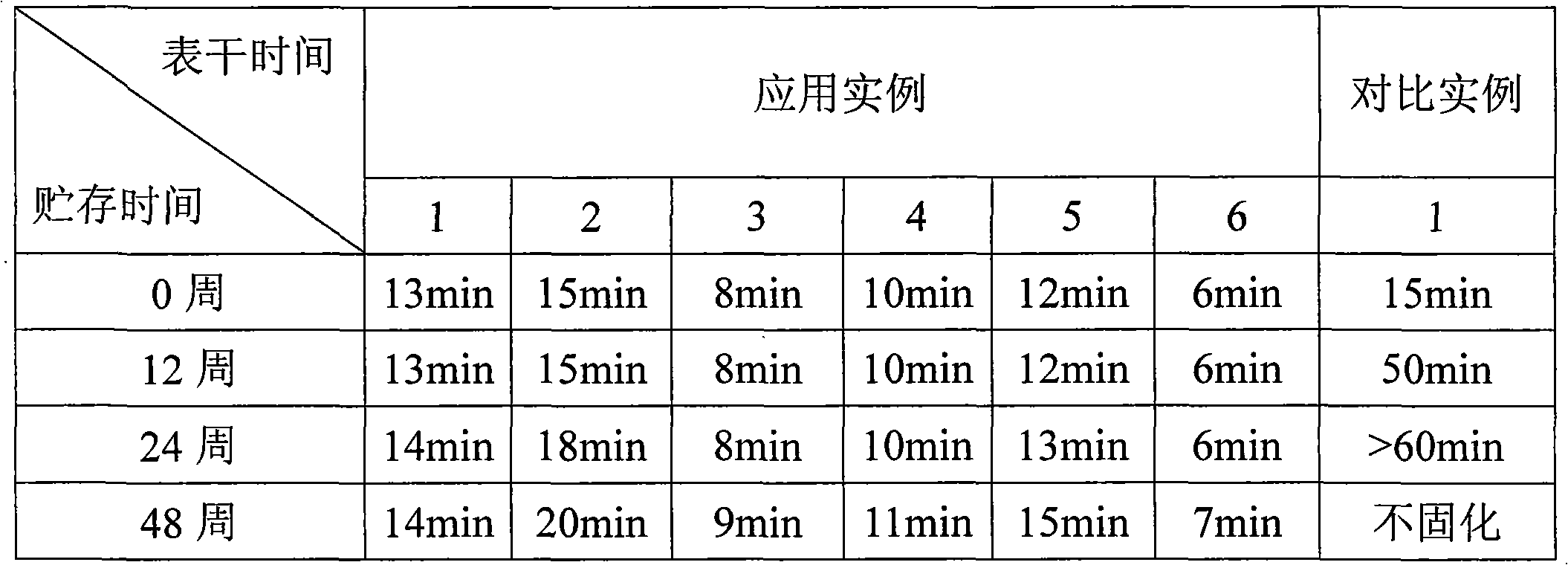

[0032] The mechanical properties, heat and humidity resistance and storage stability of the sealant are shown in Tables 1 and 2.

Embodiment 2

[0034] In parts by weight, prepare the base material according to the preparation method of the base material in Example 1, take 1000 g of the base material, add 20 g of methyltrimethoxysilane, 30 g of phenyltrimethoxysilane, stir in vacuum for 20 minutes, then add 30 g of white Carbon black and 200g molecular weight are the simethicone oil of 500, after stirring, add 30g catalyst bis(isopropoxy)bis(ethyl acetoacetate)titanium and 3g gamma-aminopropyltriethoxysilane, vacuum stir 20 Minutes later, the discharge is sealed and preserved.

[0035] The mechanical properties, heat and humidity resistance and storage stability of the sealant are shown in Tables 1 and 2.

Embodiment 3

[0037] In parts by weight, prepare the base material according to the preparation method of the base material in Example 1, take 1000 g of the base material, add 30 g of methyltrimethoxysilane, 20 g of phenyltrimethoxysilane, stir in vacuum for 20 minutes, and then add 30 g of white Carbon black and 200g of simethicone oil with a molecular weight of 500 were stirred evenly, and then 30g of the catalyst organotitanium complex D60 and 3g of γ-aminopropyltriethoxysilane were added, stirred in a vacuum for 20 minutes, and then discharged and sealed for storage.

[0038] The mechanical properties, heat and humidity resistance and storage stability of the sealant are shown in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com