Top-blown bath antimony smelting method and bath smelting furnace

A molten pool smelting furnace and molten pool smelting technology, applied in the field of metal antimony smelting, can solve the problems of difficult control, high cost of flue gas treatment, no industrial application, etc., achieve continuous and stable production, solve environmental problems, and strengthen smelting The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

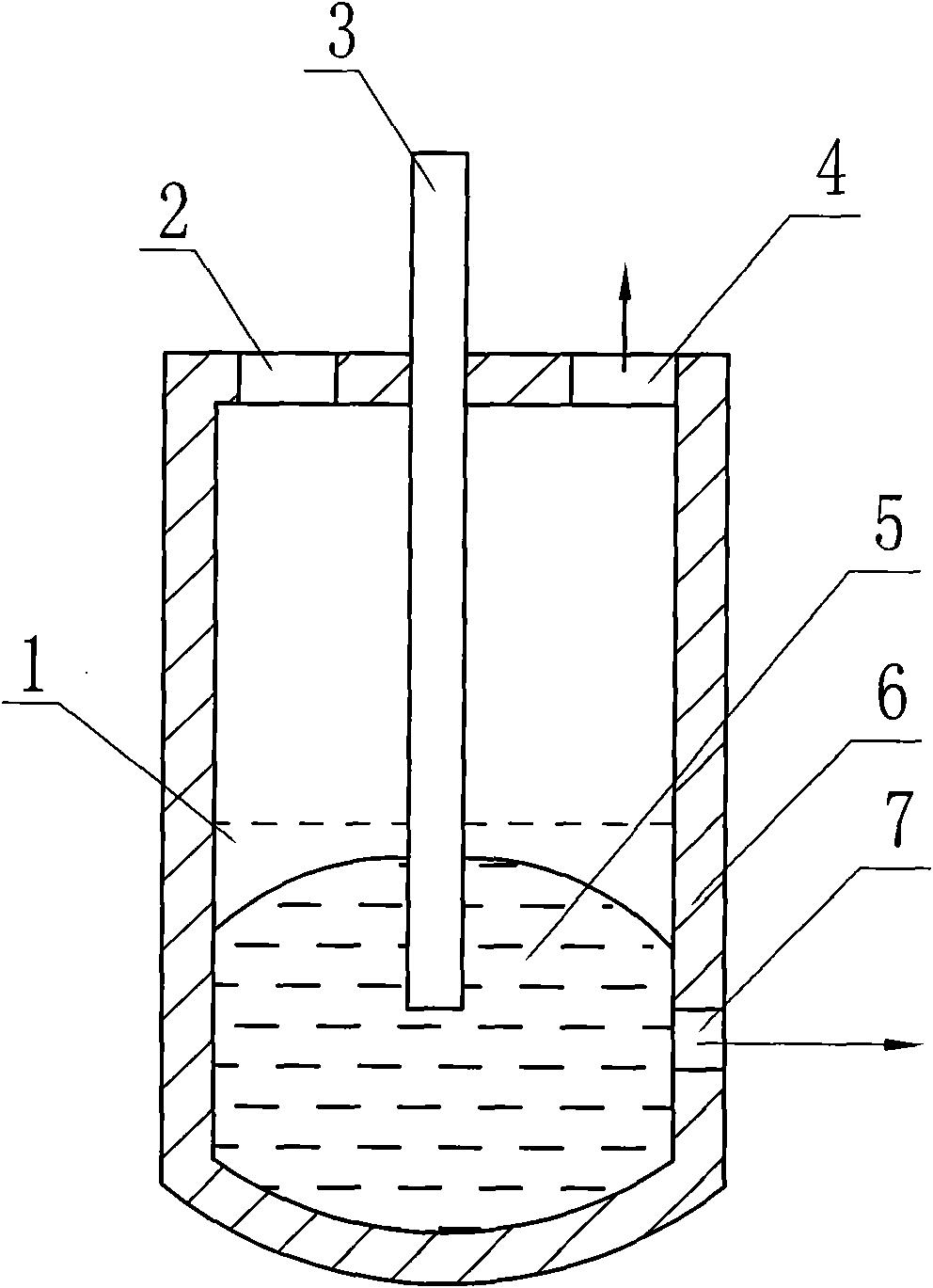

[0018] Depend on figure 2 As can be seen, a kind of melting pool smelting furnace adopting the above method comprises a body of furnace 6, the depth of the molten pool 1 of the body of furnace 6 is 1500mm-2000mm, and the upper part of the body of furnace 6, that is, the top of the furnace, is provided with a charging port 2 and is used for adding fuel, The spray gun 3 of oxygen-enriched air; the flue 4 is arranged on the top of the furnace body 6, and the bottom of the furnace body 6 is provided with a slag discharge port 7.

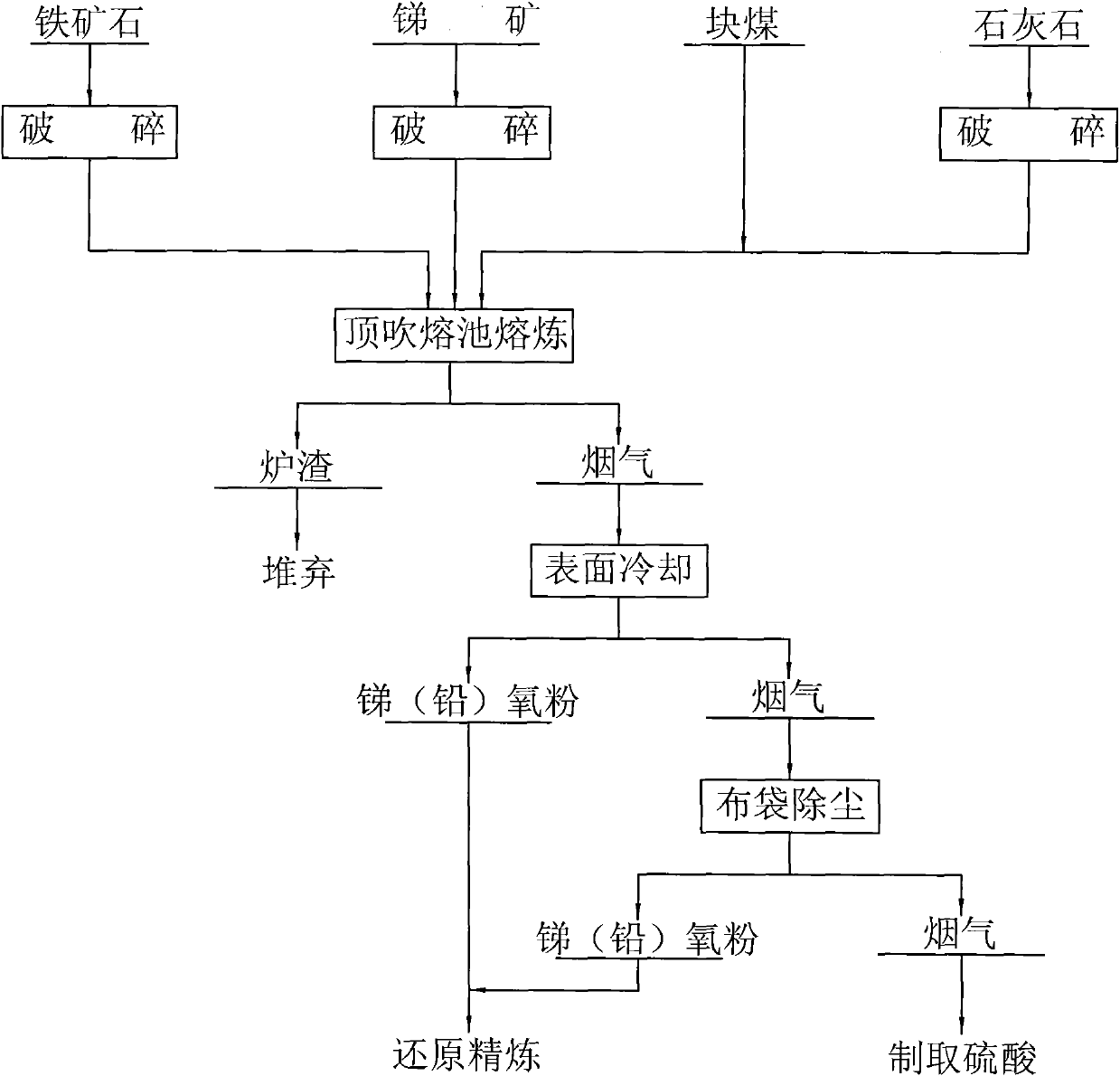

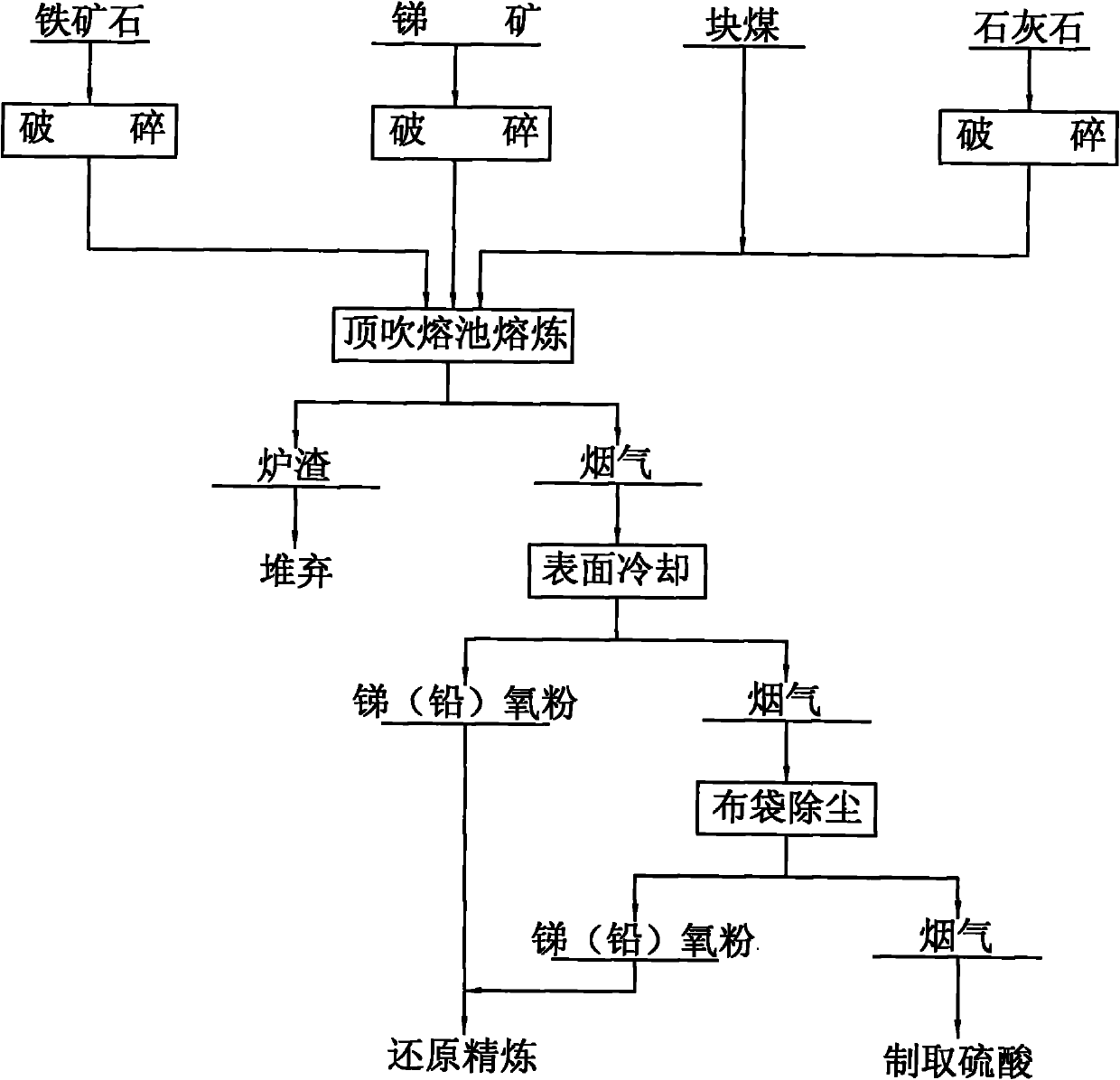

[0019] Depend on figure 1 It can be seen that a method for smelting antimony in a top-blown molten pool comprises the following steps: (1) stock preparation: the antimony ore grade contains antimony ≥ 20% (the present embodiment contains antimony 35%, and controls moisture content 10%), iron ore Stone grade contains iron 35%-60% (present embodiment is iron-containing 55%), limestone contains calcium oxide 30%-65% (present embodiment is containing calci...

Embodiment 2

[0028] In the present invention, in the step (1), the powder into the furnace is lead-antimony ore, containing 21% antimony and 25% lead, and controlling the water content of the material to be 9.5%;

[0029] In the present invention in step (2), batching is based on 100 parts of antimony ore weight, by iron ore: limestone: lump coal is 32: 15: 5 batching;

[0030]In step (3) of the present invention, the depth of the molten pool 1 is controlled at 1800mm, the melting temperature is controlled at 1280°C, pulverized coal and 50% oxygen-enriched air are sprayed into the molten pool 1 by the spray gun 3; the depth of the spray gun head inserted into the melt 5 300mm, nozzle pressure 0.20MPa.

[0031] Continuous trial production, the smelting atmosphere in the furnace is controlled to be neutral, and the slag generated in the molten pool is released continuously; the flue gas SO 2 The concentration reaches 11%, which is used to produce industrial concentrated sulfuric acid; the m...

Embodiment 3

[0038] In the present invention, in step (1), the furnace charge is antimony ore powder, containing 28% antimony, controlling the water content of the material to 9.8%, and the iron ore grade containing 46% iron;

[0039] In the present invention in step (2), batching is based on 100 parts of antimony ore weight, by iron ore: limestone: lump coal is 55: 21: 3 batching;

[0040] In step (3) of the present invention, the depth of molten pool 1 is controlled at 1700mm, the melting temperature is controlled at 1250°C, and the calorific value is 4606kJ / Nm 3 Gas and 60% oxygen-enriched air are sprayed into the molten pool 1 by the spray gun 3;

[0041] Continuous production, the smelting atmosphere in the furnace is controlled to be neutral, and the slag generated in the molten pool is released continuously; the flue gas SO 2 The concentration reaches 7.6%, which is used to produce industrial concentrated sulfuric acid; the antimony oxygen powder contains antimony ≥ 80%, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com