Developer solution for positive lithoprinting plate

A technology of developing solution and lithography, applied in the field of developing solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of developing solution

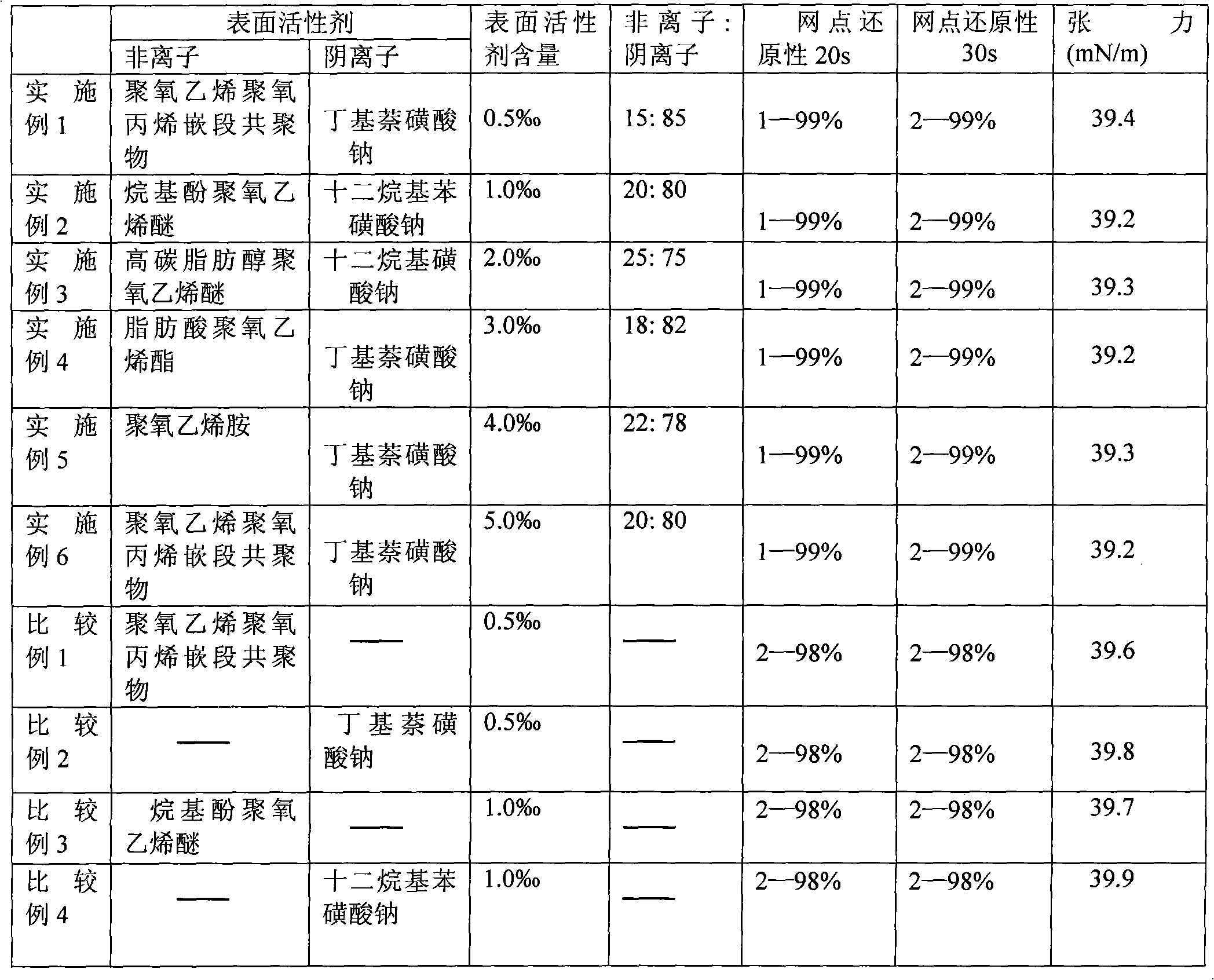

[0023] Take 200-250ml of deionized water, add 70-75ml of sodium hydroxide (its silicon dioxide content is 8.22%, and its modulus is 3.4), and then adjust its modulus with sodium hydroxide or potassium hydroxide to make its modulus Keep it between 1.2 and 1.5, then add nonionic surfactant polyoxyethylene polyoxypropylene block copolymer and anionic surfactant sodium butylnaphthalene sulfonate, the total content is 0.5‰, nonionic surfactant and The ratio of anionic surfactant is 15:85, and finally add 1% benzyl alcohol solvent and 2% corrosion inhibitor sodium gluconate. Stirring was continued for 3 hours. Check its surface tension. The results are shown in Table 2.

[0024] (2) Development

[0025] The plate-making and developing conditions are shown in Table 1. The prepared plate was developed in a developer solution, developed by a machine, and the developing time was 20s, 30s, and the dot reduction performance was tested. ...

Embodiment 2

[0027] (1) Preparation of developing solution

[0028] Take 200-250ml of deionized water, add 70-75ml of sodium hydroxide (its silicon dioxide content is 8.22%, and its modulus is 3.4), and then adjust its modulus with sodium hydroxide or potassium hydroxide to make its modulus Keep it between 1.2 and 1.5, then add nonionic surfactant alkylphenol polyoxyethylene ether and anionic surfactant sodium dodecylbenzenesulfonate, the total weight content is 1.0‰, nonionic surfactant and The ratio of anionic surfactant is 20:80, and finally add 2% benzyl alcohol solvent and 0.1% corrosion inhibitor sodium gluconate. Stirring was continued for 5 hours. Check its surface tension. The results are shown in Table 2.

[0029] (2) Development

[0030] Plate making and developing conditions are shown in Table 1. Use the prepared plate to develop in the developer solution, adopt machine development, the development time is 20s and 30s, and test the dot reduction performance. The results a...

Embodiment 3

[0032] (1) Preparation of developing solution

[0033] Take 200-250ml of deionized water, add 70-75ml of sodium hydroxide (its silicon dioxide content is 8.22%, and its modulus is 3.4), and then adjust its modulus with sodium hydroxide or potassium hydroxide to make its modulus Keep it between 1.2 and 1.5, then add nonionic surfactant high-carbon fatty alcohol polyoxyethylene ether and anionic surfactant sodium dodecylsulfonate, the total content is 2‰, nonionic surfactant and The ratio of anionic surfactant is 25:75, and finally add 4% benzyl alcohol and 0.5% glycerin solvent. Then add 10% corrosion inhibitor tetramethylammonium chloride. Stirring was continued for 4 hours. Check its surface tension. The results are shown in Table 2.

[0034] (2) Development

[0035] Plate making and developing conditions are shown in Table 1. Use the prepared plate to develop in the developer solution, adopt machine development, the development time is 20s and 30s, and test the dot red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com