Method for improving yield of concentrated phosphoric acid

A production method, phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low production start-up rate and load rate, poor heat transfer effect, etc., to achieve increased phosphoric acid output and high application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Follow the steps below to concentrate phosphoric acid:

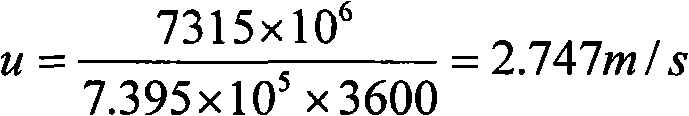

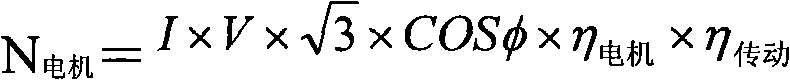

[0037] The concentration system adopts vacuum evaporation and forced circulation process. The circulation loop consists of a flash chamber, a graphite heat exchanger, an axial flow circulation pump (with a speed of 500 rpm) and connecting pipes. Dilute phosphoric acid with a mass percentage concentration of 26-28% is added to the circulation loop by the dilute acid feed pump before the circulation pump and mixed with a large amount of circulating concentrated acid. The low-pressure steam enters the graphite heat exchanger for heat exchange with the circulating acid. The scale inhibitor phosphonocarboxylic acid polymer is added to the graphite heat exchanger. The inlet steam pressure of the graphite heat exchanger is 105KPa, and the acid inlet temperature is 77.3°C. The steam temperature is 121°C, the system is under an absolute pressure of about 13KPa, the phosphoric acid boils vigorously, and the water in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com