New method for preparing picoplatin

A technology of picoplatin and picoline, which is applied in the field of preparation of anti-tumor drug picoplatin, can solve the problems of complicated production process requirements, increased manufacturing costs, complicated purification process, etc., and achieve the effect of convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

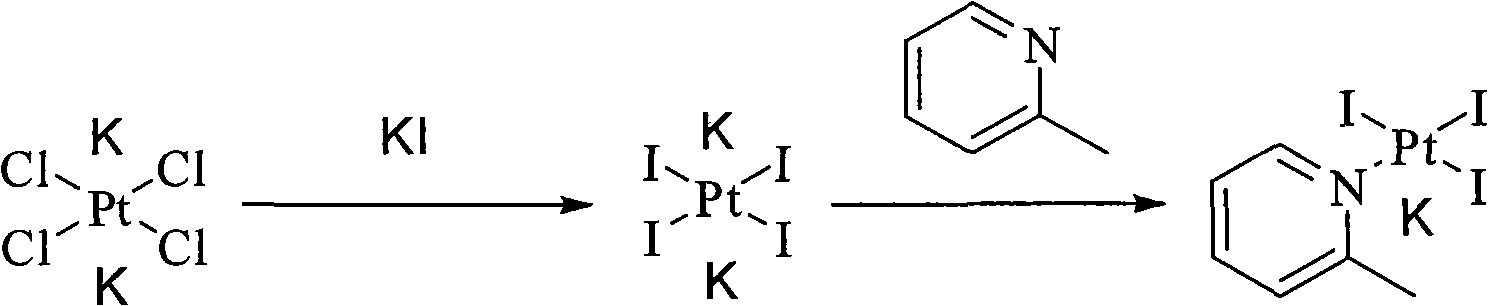

Method used

Image

Examples

Embodiment 1

[0050] This example illustrates the preparation of picoplatin.

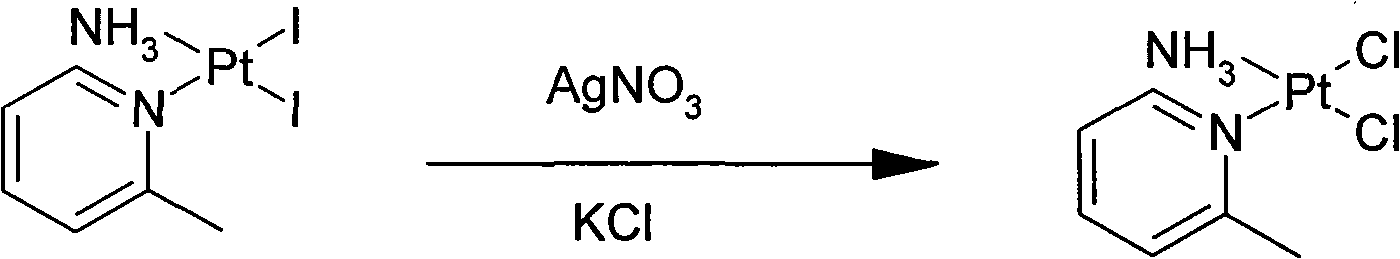

[0051] In the reaction flask, add K under dark conditions 2 PtCl 4 (103.8g, 0.25mol), 1500mL of deionized water, and 500mL of an aqueous solution in which KI (166g, 1mol) was dissolved was added, and the mixture was stirred at 25°C for 2 hours. 2-Methylpyridine (23.3 g, 0.25 mol) was slowly added dropwise, and the mixture was stirred at 25°C for 8 hours. Filter and dry under reduced pressure to obtain potassium triiodo(2-picoline)platinate(II) potassium (170.0 g, 0.24 mol) in the form of brown crystalline powder, with a yield of 96%, and store it in an airtight and dark place for future use;

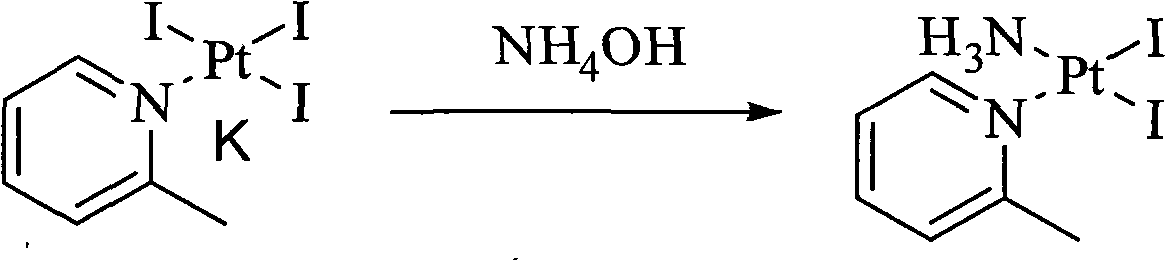

[0052] Potassium triiodo (2-picoline) platinum (II) (170.0 g, 0.24 mol), 25% ammonia (16.3 g, 0.24 mol), and 2000 mL of deionized water were stirred at room temperature and protected from light. Mix evenly, stir at 25°C for 8 hours, filter, wash the filter cake with pure water, and dry under vacuum at 45°C to obtain cis-...

Embodiment 2

[0055] The preparation method of the picoplatin of this embodiment is the same as that of Example 1, but the reaction conditions are changed.

[0056] In the reaction flask, add K under dark conditions 2 PtCl 4 (103.8g, 0.25mol), 1500mL of deionized water, and 500mL of an aqueous solution in which KI (166g, 1mol) was dissolved was added, and the mixture was stirred at 30°C for 2 hours. 2-Methylpyridine (23.3 g, 0.25 mol) was slowly added dropwise, and the mixture was stirred at 30° C. for 8 hours. Filtrate and dry under reduced pressure to obtain potassium triiodo(2-picoline)platinate(II) potassium (163.0 g, 0.23 mol) in the form of brown crystalline powder, with a yield of 92%, and store it in an airtight and dark place for future use;

[0057] Potassium triiodo (2-picoline) platinum (II) (163.0 g, 0.23 mol), 25% ammonia (15.6 g, 0.23 mol), and 2000 mL of deionized water were stirred at room temperature and protected from light. Mix well, stir at 30°C for 8 hours, filter, ...

Embodiment 3

[0060] The preparation method of the picoplatin of this embodiment is the same as that of Example 1, but the reaction conditions are changed.

[0061] In the reaction flask, add K under dark conditions 2 PtCl 4 (103.8g, 0.25mol), 1500mL of deionized water, and 500mL of an aqueous solution in which KI (166g, 1mol) was dissolved was added, and the mixture was stirred at 15°C for 1 hour. 2-Methylpyridine (23.3 g, 0.25 mol) was slowly added dropwise, and the mixture was stirred at 15° C. for 8 hours. Filter and dry under reduced pressure to obtain potassium triiodo(2-picoline)platinate(II) potassium (172.0 g, 0.24 mol) in the form of brown crystalline powder, with a yield of 97%, and store it in a sealed and dark place for future use;

[0062] Potassium triiodo (2-picoline) platinum (II) (172.0 g, 0.24 mol), 25% ammonia (16.3 g, 0.24 mol), and 2000 mL of deionized water were stirred at room temperature and protected from light. Mix evenly, stir at 15°C for 8 hours, filter, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com