A modified water-absorbing bead nanocomposite material and its preparation method and application

A composite material and nano-bead technology, applied in chemical instruments and methods, other chemical processes, restoration of polluted soil, etc., can solve the problems of low removal efficiency of heavy metals, large number of atoms occupied by the surface, large specific surface area, etc., and achieve a solution Not suitable for recycling and easy to reunite, good water absorption, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

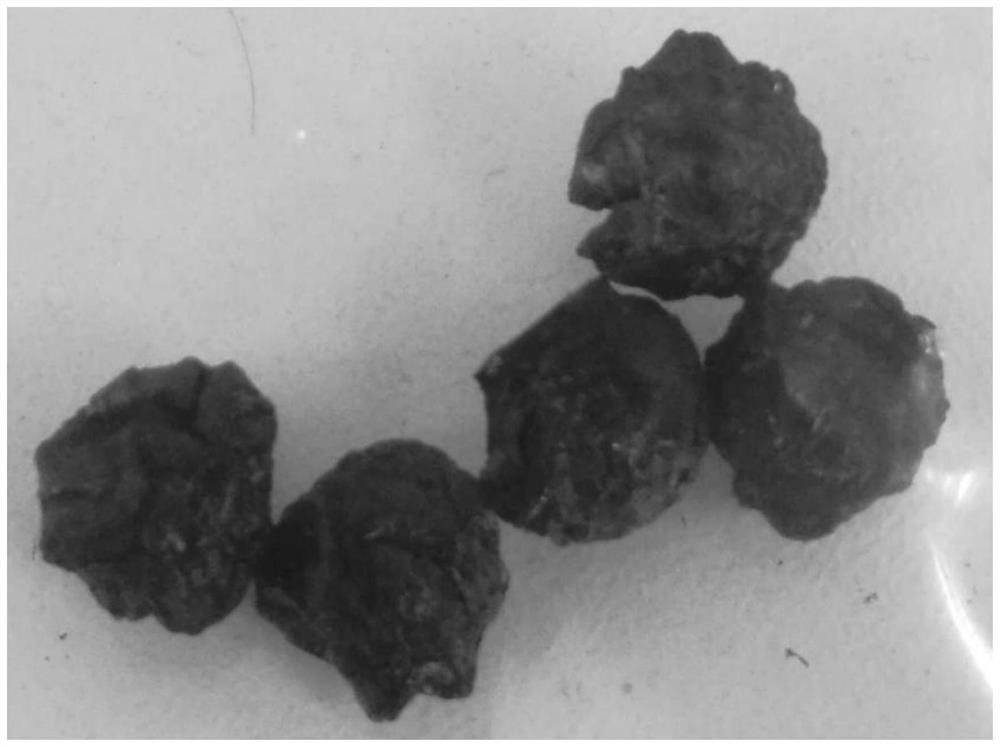

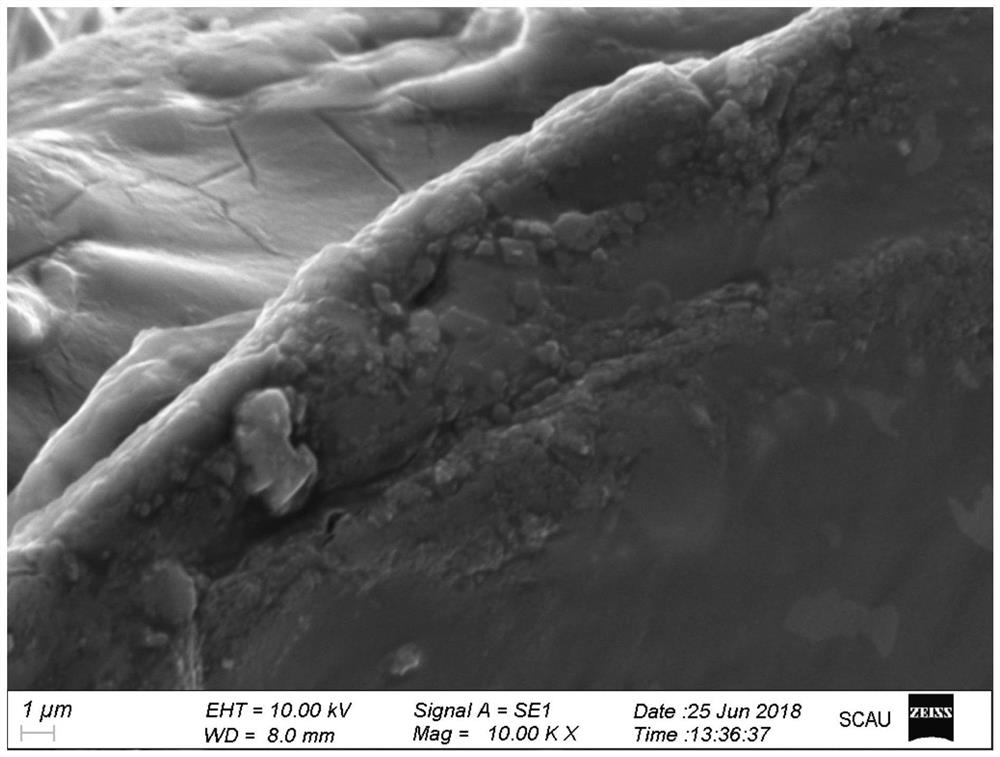

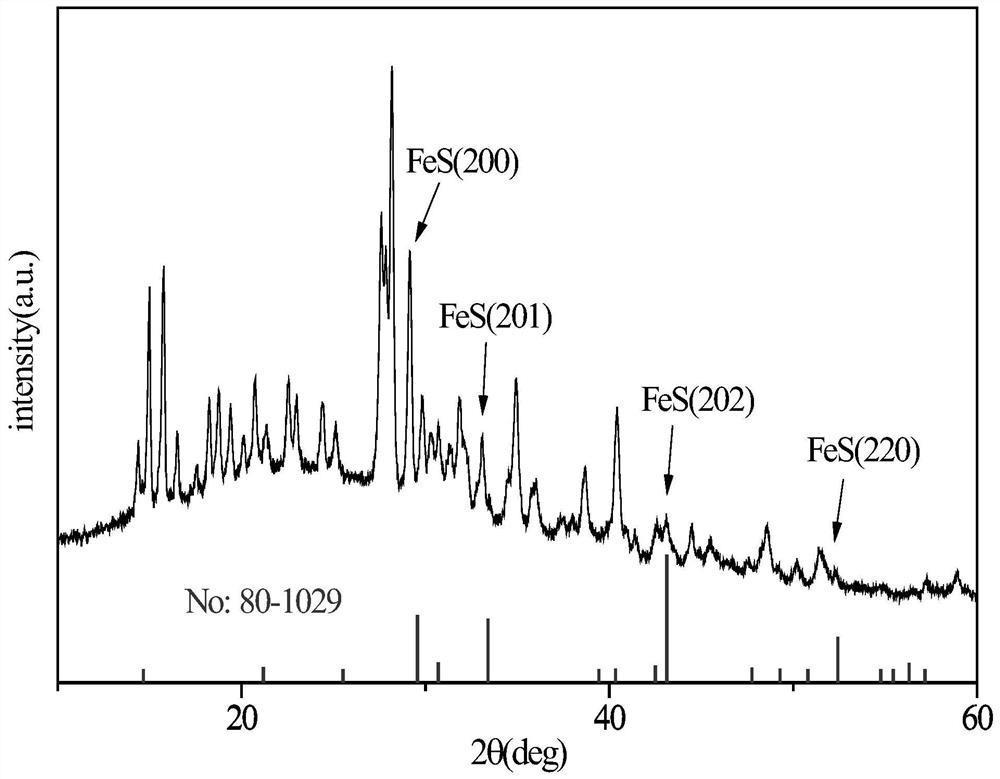

[0039] (1) Soak 5g of water-absorbing beads (purchased in Shuyang Tianba Landscaping Co., Ltd., a transparent water-absorbing bead product) in 0.2mol / L ferrous chloride solution for 6h, stir constantly, and pass nitrogen in the reaction solution throughout the whole process, and then Rinse the water-absorbing beads with deionized water (the water used needs to be ventilated with nitrogen for at least 10 minutes to remove the oxygen inside), put it in the refrigerator at -20°C for 12 hours, and then freeze-dry for 12 hours;

[0040] (2) Put the water-absorbing beads obtained in (1) into a 0.2mol / L sodium sulfide solution and soak for 12 hours, stir constantly, pass nitrogen gas throughout the whole process, and then use deionized water (the water used needs to pass nitrogen gas for at least 10 minutes to remove the inner Oxygen) flushing, put into the refrigerator at -20°C for 12 hours, and then freeze-dry for 12 hours to obtain the modified water-absorbing bead nanocomposite. ...

Embodiment 2

[0044] (1) Soak 20g of water-absorbing beads in 1mol / L ferrous chloride solution for 12 hours, stir constantly, pass nitrogen throughout the process, and then use deionized water (the water used needs to pass nitrogen for at least 10 minutes to remove the oxygen inside) Rinse the water-absorbing beads, put them in the refrigerator at -20°C for 2 hours, and then freeze-dry for 24 hours;

[0045] (2) Soak the water-absorbing beads obtained in (1) in 1mol / L sodium sulfide solution for 24 hours, stir continuously, pass nitrogen throughout the process, then rinse with deionized water, put them in the refrigerator at -20°C for 2 hours, and then freeze-dry After 24 hours, the modified water-absorbing bead nanocomposite material can be obtained.

[0046] (3) Repeat steps (1) and (2) once to increase the load.

Embodiment 3

[0048] (1) Soak 10g of water-absorbing beads in 0.5mol / L ferrous sulfate solution for 8 hours, keep stirring, pass nitrogen gas through the reaction solution throughout the process, then rinse the water-absorbing beads with deionized water, put them in the refrigerator for 12 hours at -10°C Afterwards, freeze-dry 18h;

[0049] (2) Soak the water-absorbing beads obtained in (1) in 0.8mol / L sodium sulfide solution for 15 hours, stir continuously, pass nitrogen gas all the way, rinse with deionized water, put in the refrigerator at -10°C for 12 hours, and then freeze After drying for 16 hours, the modified water-absorbing bead nanocomposite material can be obtained.

[0050] (3) Repeat steps (1) and (2) once to increase the load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com