Novel water-soluble phenolic resin and preparation method thereof

A water-soluble phenolic resin, phenolic resin technology, applied in the direction of adhesive types, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve the problem that rubber adhesives cannot fully meet the performance of motor vehicle clutch friction plates requirements, affecting the safety of motor vehicles, reducing friction coefficient, etc., to achieve good production prospects and market application prospects, easy mass production, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The water-soluble phenolic resin of the present invention is made of phenol and formaldehyde as main raw materials, and sodium hydroxide as a catalyst, and is prepared through condensation reaction under strict production process conditions.

[0013] The production technology of water-soluble phenolic resin of the present invention is:

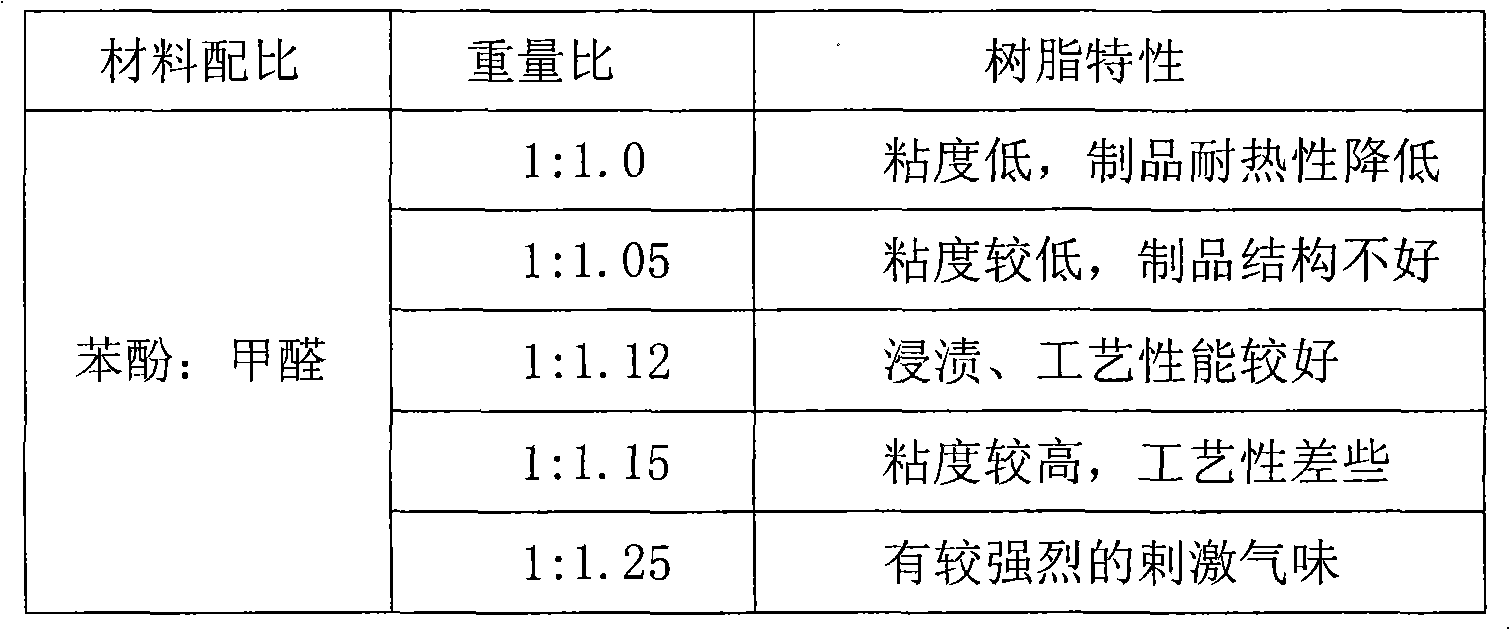

[0014] (1) Check the measuring tools and production equipment used in resin production, and then inspect the ingredients of various raw materials, accurately weigh 100 parts by weight of phenol and 105 to 115 parts by weight of formaldehyde as raw materials, put them into the resin reaction container, and then 0.1 to 0.2 parts by weight of the basic catalyst are put in, and heating and stirring are started.

[0015] (2) When the material heating temperature reaches 85°C, stop heating and continue stirring, and stop stirring when the material temperature reaches 95°C.

[0016] (3) Note that when the temperature reaches 98°C, the materia...

Embodiment 2

[0028] The water-soluble phenolic resin prepared according to the technical scheme of Example 1 of the present invention can be mixed with water, and has the characteristics of water samples, so it is called water-soluble phenolic resin. It is quite different from general phenolic resin in its mixing properties with water. Because the general liquid phenolic resin is alcohol-soluble, it can only use alcohols, such as alcohol or methanol, as the most commonly used solvent, or dissolve it in alcohol first, and then add a little water. Therefore, phenolic resin is also called alcohol-soluble phenolic resin, and it cannot simply use water as a solvent. This is also one of the main differences between the water-soluble phenolic resin of the present invention and common phenolic resins.

Embodiment 3

[0030] The water-based resin prepared according to the technical solution of Example 1 of the present invention has the characteristics of good stability. Store the resin under natural conditions. After the room temperature does not exceed 50°C, and it is stored at room temperature for 500 hours, the water-based resin has no change or dehydration phenomenon, which shows that the stability of the resin can meet the production requirements.

[0031] After testing, the water-soluble phenolic resin of the present invention can be placed under natural conditions for up to 725 hours, and it is found that turbidity begins to appear, and stratification occurs in 783 hours, resulting in dehydration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com