Medium-temperature and high-temperature clean fracturing fluid and preparation method thereof

A clean fracturing fluid, medium and high temperature technology, applied in the field of fracturing fluid, can solve the problems of limited popularization and application, poor temperature resistance of clean fracturing fluid system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

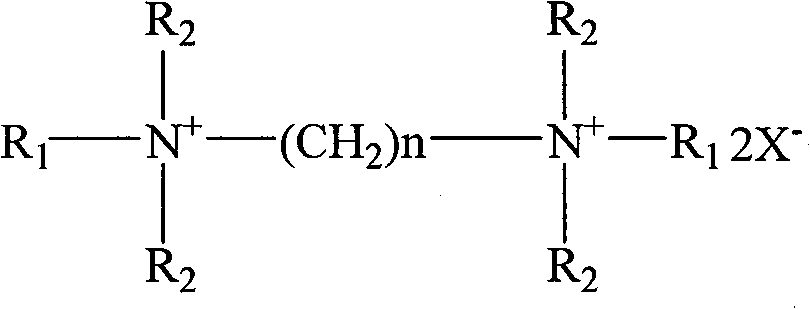

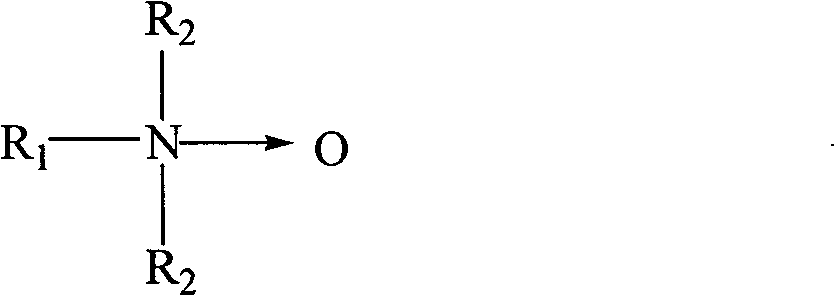

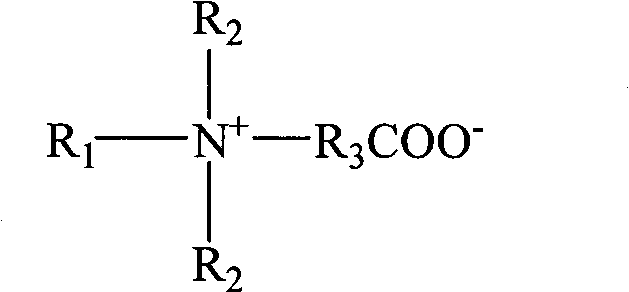

Method used

Image

Examples

Embodiment 1

[0044] First, Gemini cationic surfactant ethylene bis(octadecyl dimethyl ammonium chloride), amphoteric surfactant cetyl dimethyl amine oxide, cosolvent methanol and water are mixed evenly to obtain a uniform transparent liquid. Then, in the transparent liquid, the aqueous solution of electrolyte salt potassium chloride and counterion sodium salicylate is mixed under stirring condition to obtain, said its mass percent is 2% of Gemini cationic surfactant, 1% of amphoteric surfactant, 1% electrolyte salt, 0.05% counter ion, 0.5% co-solvent, and the balance is water. The medium-high temperature clean fracturing fluid obtained in this example was heated at 25°C for 170s -1 The viscosity under shear is greater than 180mPa·s, at 90°C, 110°C, 130°C, 170S -1 Shearing for 60 minutes, its viscosity is 127mPa s, 86mPa s, 36mPa s respectively. It has good temperature resistance, shear resistance and sand carrying performance, which fully meets the sand carrying requirements of oil and ga...

Embodiment 2

[0046] First, Gemini cationic surfactant propylene bis(octadecyl dimethyl ammonium chloride), amphoteric surfactant octadecyl dimethyl amine oxide, co-solvent isopropanol and water are evenly mixed to obtain a uniform transparent liquid , then add the aqueous solution of electrolyte salt sodium chloride and counterion sodium lauryl sulfate to the transparent liquid under stirring conditions and mix uniformly to obtain, said its mass percentage is Gemini cationic surfactant 5%, amphoteric surfactant 1%, electrolyte salt 3%, counter ion 0.1%, co-solvent 0.8%, and the balance is water. The medium-high temperature clean fracturing fluid obtained in this example is at 90°C, 110°C, 130°C, 170S -1 After shearing for 60 minutes, the viscosities are 181mPa·s, 120mPa·s, and 67mPa·s respectively.

Embodiment 3

[0048] First, the Gemini cationic surfactant ethylene bis(octadecyl dihydroxyethyl ammonium chloride), the amphoteric surfactant tallow dimethyl amine oxide, the cosolvent glycerin and water are evenly mixed to obtain a uniform transparent liquid , then add electrolyte salt ammonium chloride and counter ion sodium dodecylbenzenesulfonate aqueous solution to the transparent liquid under stirring conditions and mix uniformly to obtain, said its mass percentage is Gemini cationic surfactant 3%, amphoteric surface Activator 2%, electrolyte salt 2%, counter ion 0.08%, cosolvent 0.1%, and the balance is water. The medium-high temperature clean fracturing fluid obtained in this example is at 90°C, 110°C, 130°C, 170S -1 After shearing for 60 minutes, the viscosities are 178mPa·s, 120mPa·s, and 70mPa·s respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com