Drying device with effects of energy conservation and environmental protection

A drying equipment, energy-saving and environmental protection technology, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of polluting gas, waste of heat source, consumption of large energy, etc., to achieve low heat loss, low additional loss, Make full use of the effect of thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

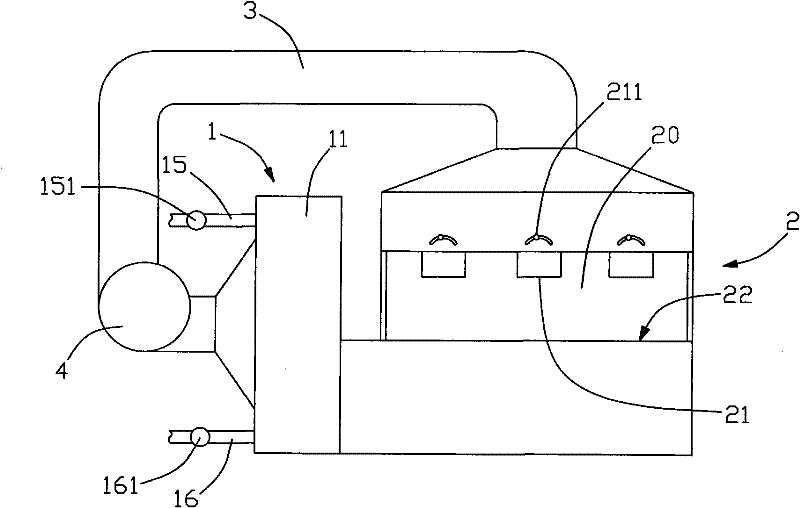

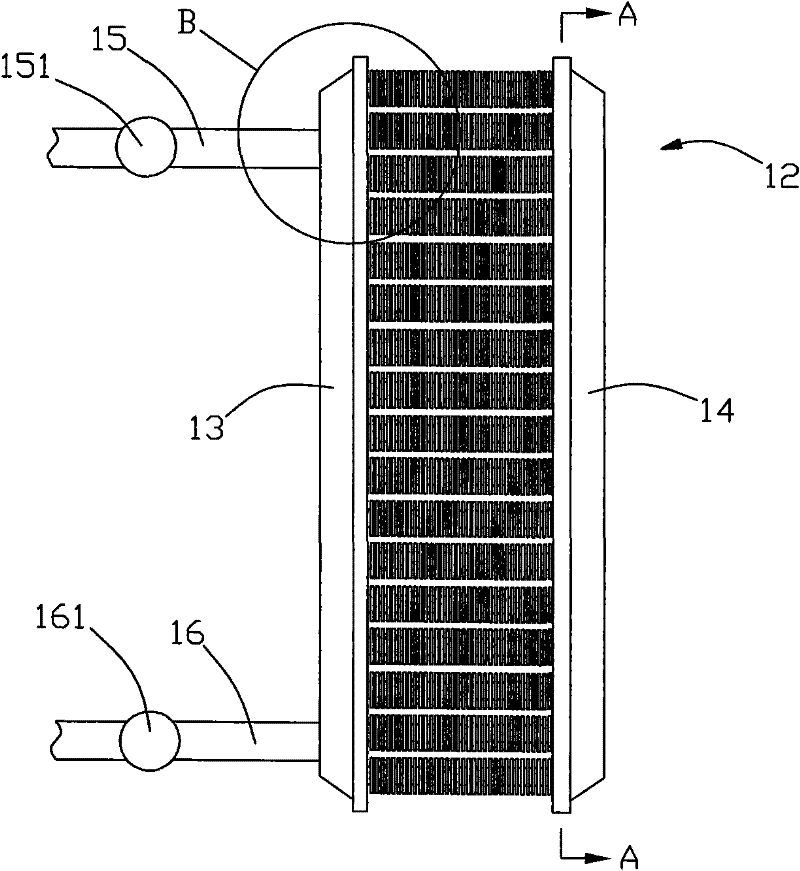

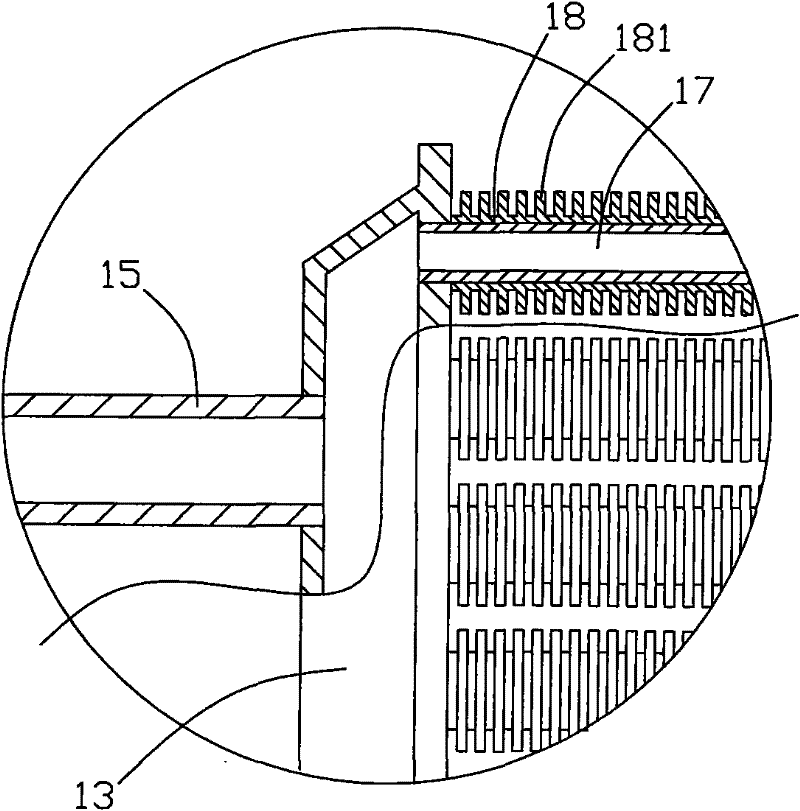

[0027] A kind of drying equipment with energy saving and environmental protection effect, refer to figure 1 , including a heating device 1 and a working box 2. refer to figure 1 and figure 2 , the heating device 1 includes a heating box 11, the heating box 11 is provided with a heating body 12, the heating body 12 is provided with a hot gas inlet 15 and a discharge port 16 connected to the inner cavity, and the hot gas inlet 15 is filled with hot waste gas Or high-temperature steam, hot waste gas or high-temperature steam exchanges heat with the heating element 12, and discharges condensed water and partially cooled gas at the discharge port 16. Therefore, the drying equipment can make full use of the waste heat discharged from the existing factory or the high-temperature steam generated by the existing boiler as a heat source, without consuming additional electricity, coal, oil energy, and will not generate additional polluting gas emissions. The drained condensate can al...

Embodiment 2

[0035] refer to Figure 5 , the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that an air outlet 21 is provided on the top of the working space 20, and the air outlet 21 communicates with the air outlet of the heating box 1, and the bottom of the side wall is provided with an air outlet 21. There is an air suction port, and the air suction port communicates with the air inlet of the heating box 1 , and the working space 20 is provided with a conveying device 23 for moving the to-be-dried objects in the working space. This embodiment is suitable for larger workpieces, and the conveying device 23 can be a belt conveying device, a chain conveying device, etc. according to specific needs.

[0036] This embodiment may also include a control box, which is connected with the frequency conversion fan 4, the pressure control valves 151, 161 and the conveying device 23 to realize comprehensive control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com