Processing method for manufacturing teeth of cylindrical gears by turning

A tooth processing and turning technology, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of low processing efficiency, high cost, and low precision, and achieve high cutting efficiency and simple equipment manufacturing , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

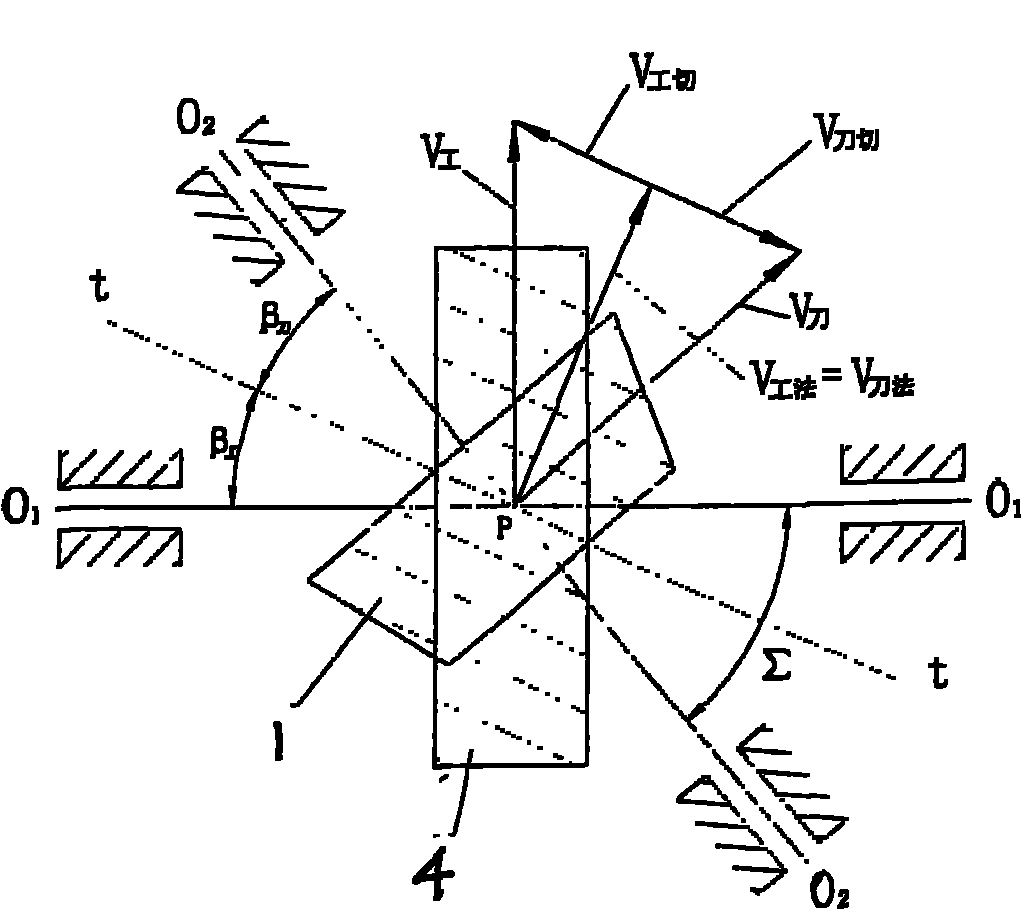

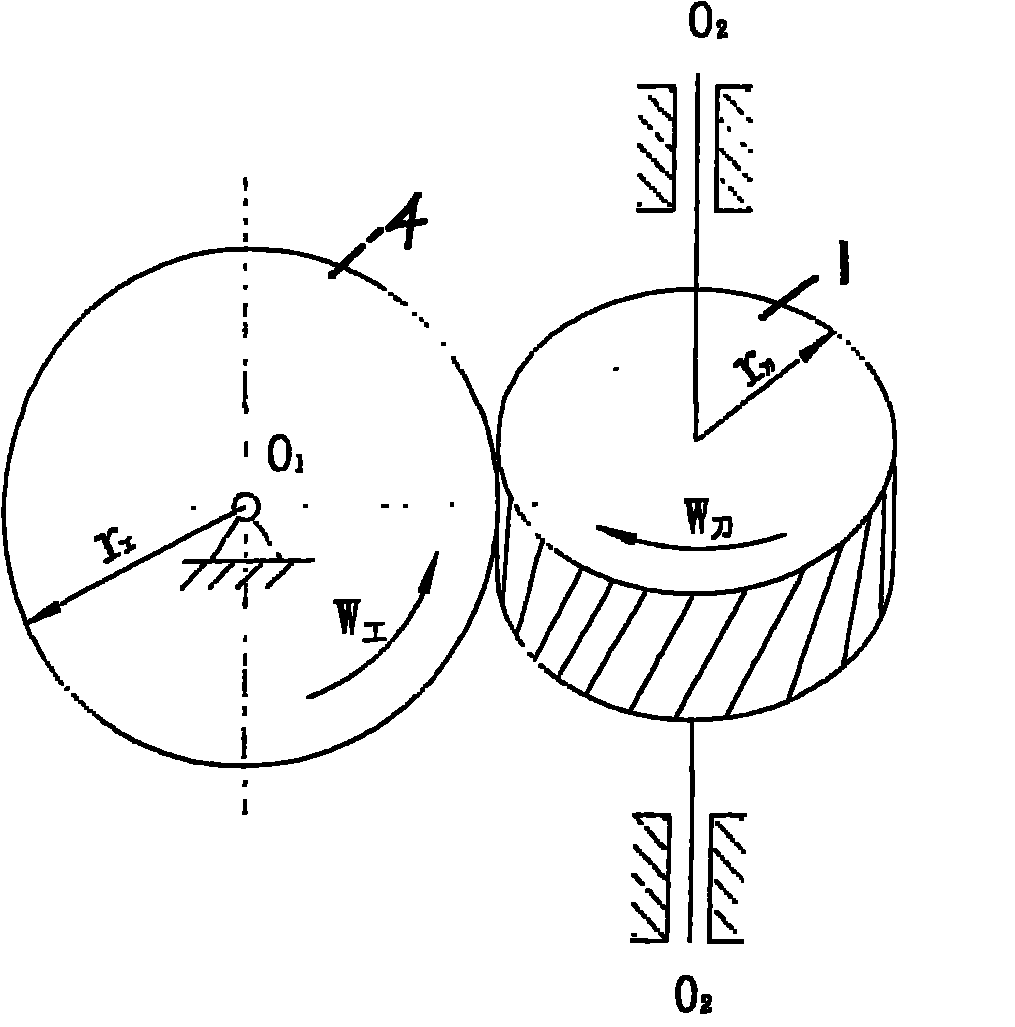

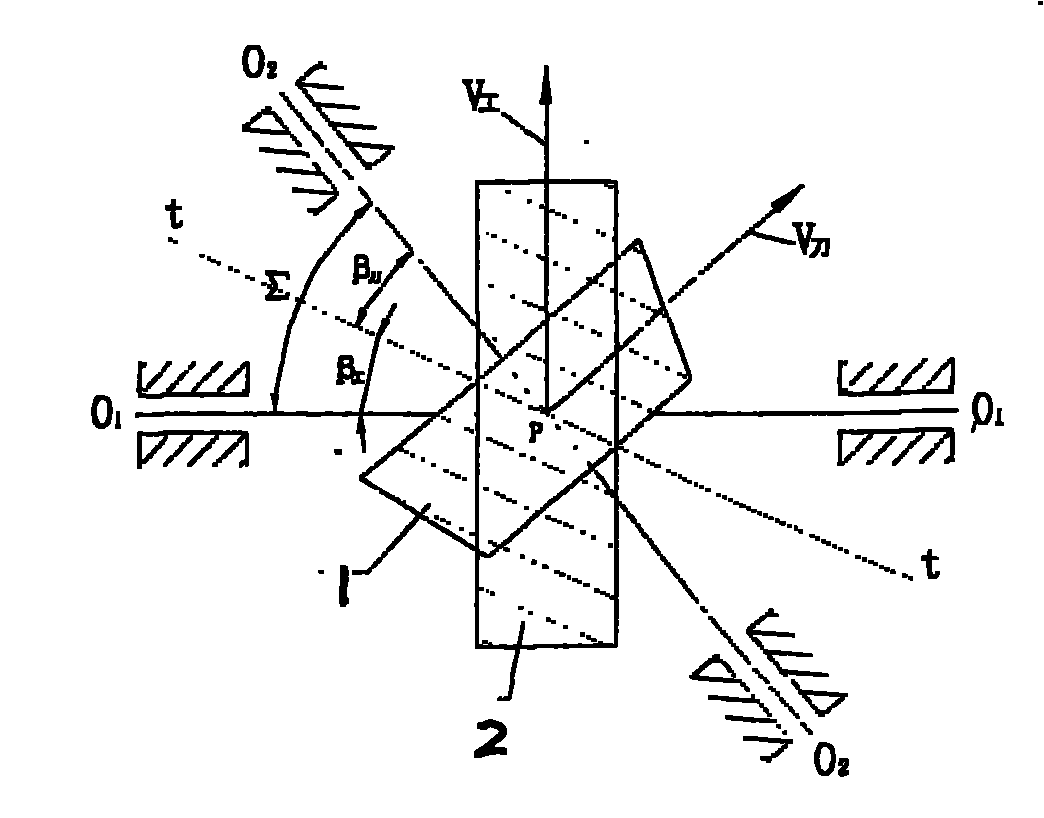

[0022] The following will be described in detail in conjunction with accompanying drawings 1 and 2 . As shown in Figure 1, one of the gears is replaced with a gear-shaping tool whose tooth shape parameters match it. According to the principle of cross-axis helical gear meshing transmission, the workpiece and the tool are strictly in accordance with a pair of cross-axis helical gear transmission relationship. When the relative rotation is performed, the teeth can be continuously cut out on the workpiece, and then the workpiece can be moved along the axial direction to cut out the entire tooth width. This process involves two movements: the strictly proportional relative rotational movement of the tool and the workpiece to form the involute (generatrix), and the tooth width (conductor) formed by the movement of the workpiece along the axis. The various angles of the tool, such as rake angle and rear angle, are the same as ordinary gear shaping cutters.

[0023] As we all know, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com