Caffeine production wastewater treatment method

A technology for producing wastewater and treatment methods, applied in biological water/sewage treatment, natural water treatment, sustainable biological treatment, etc. Decolorization function, high adsorption coagulation activity, the effect of overcoming polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

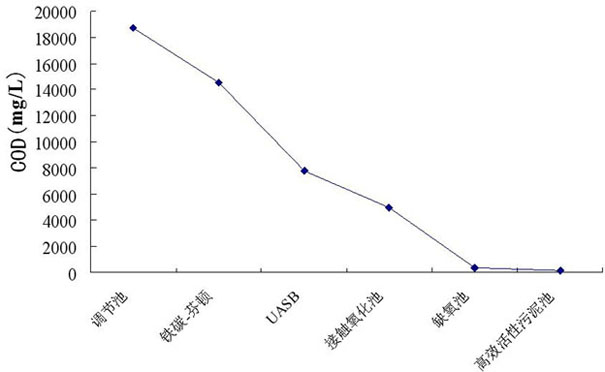

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the treatment method of caffeine production wastewater in this embodiment is as follows: one, the caffeine production wastewater is passed into the regulating tank, the pH of the wastewater is adjusted to 4 ~ 8, and the hydraulic retention time is 1 ~ 4h; The effluent of the pool is connected to the iron-carbon-Fenton oxidation pool, and then the volume concentration is 0.10L / m 3 ~0.50L / m 3 Add hydrogen peroxide into the iron-carbon-Fenton oxidation tank, and adjust the pH value to 4~5, and the hydraulic retention time to 2.0h~5h, in which Fe 2+ The concentration is 50~200mg / L; 3. Connect the effluent from the iron-carbon-Fenton oxidation tank to the air flotation tank, and the hydraulic retention time is 1 to 4 hours; 4. Connect the effluent from the air flotation tank to the upflow anaerobic sludge bed (UASB), the concentration of anaerobic sludge in the reactor is 15kg / m 3 ~30kg / m 3 , oxidation-reduction potential ORP3 ~20kg / m 3, the diss...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, concentrated sulfuric acid with a mass concentration of 98% is used to adjust the pH of the wastewater to 4-8. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, concentrated sulfuric acid with a mass concentration of 98% is used to adjust the pH value to 4-5. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com