High ammonia nitrogen sewage processing method

A sewage treatment method, high ammonia nitrogen technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of water body deterioration, air pollution, high operating costs, etc., to achieve Fast separation of mud and water, reduced water pollution, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

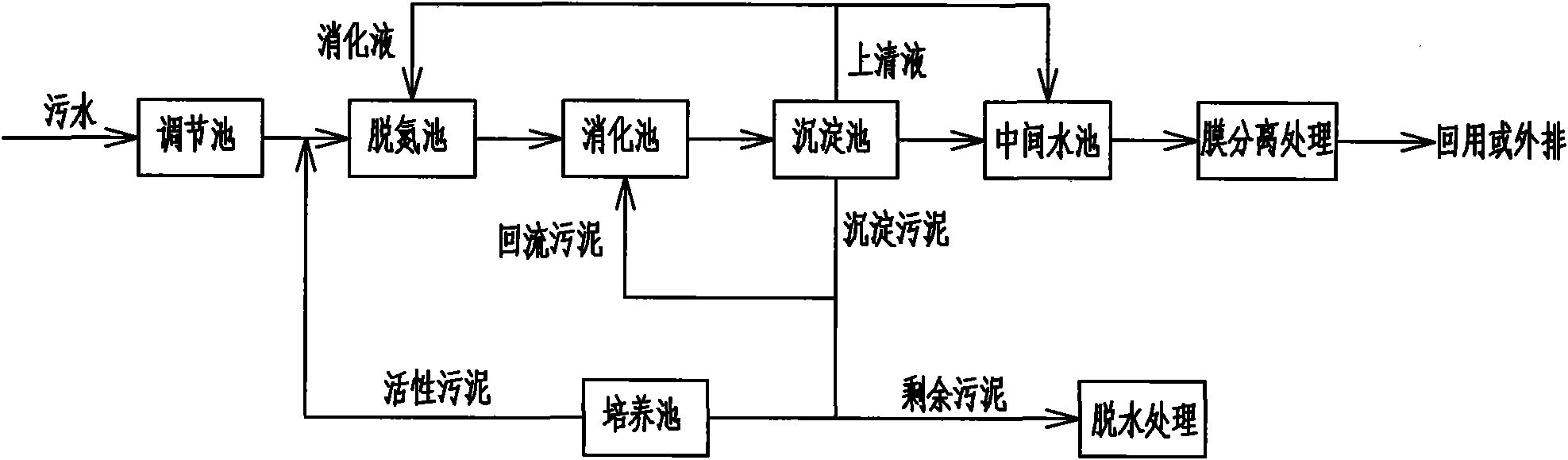

Method used

Image

Examples

Embodiment 1

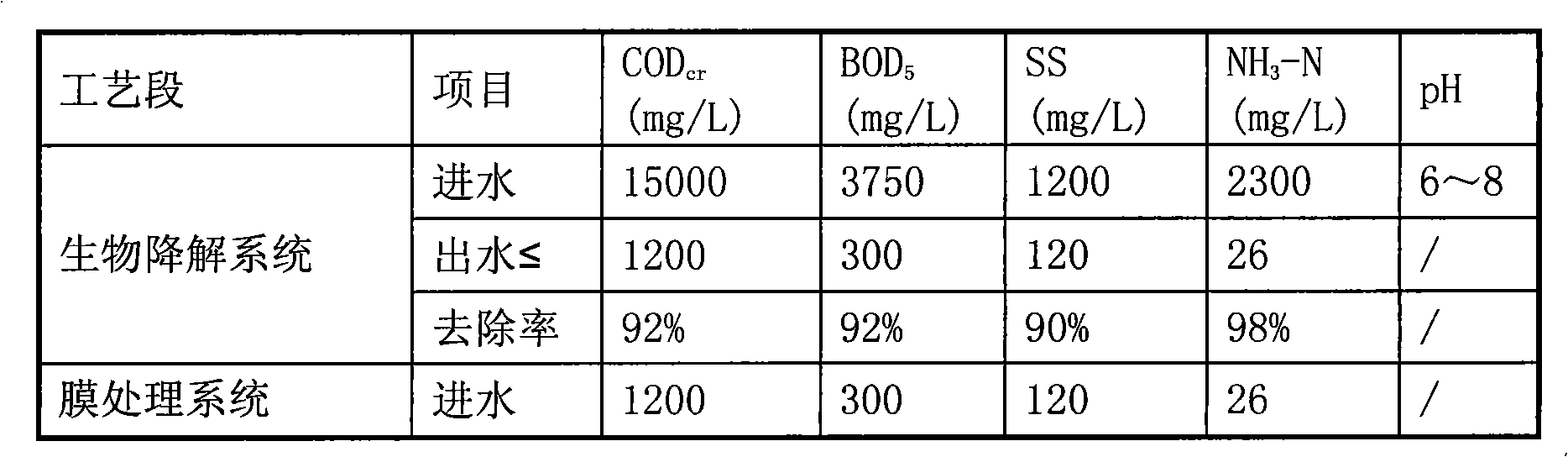

[0025] The high-ammonia-nitrogen sewage produced by a paper mill adopts the method of the present invention, and the total water volume designed to be treated is 800t / d, and it is designed to operate continuously for 24 hours a day; the influent flow rate of the membrane treatment unit is 33.3m 3 / h; the type of humus in the filler used in the preparation of activated sludge in this example is SH350, and this type of humus is purchased from Japan Zhaorui Co., Ltd., and the particle size of the silica in the filler is 1 mm to 4 mm.

[0026] 1. Influent water quality

[0027] Table 1 Influent water quality of high ammonia nitrogen sewage (unit: mg / l; pH value is dimensionless)

[0028]

Pollutant index

COD Cr

BOD 5

NH 3 -N

SS

TN

(μS / cm)

pH

Concentration of pollutants

15000

3750

2300

1200

2500

25000

6~8

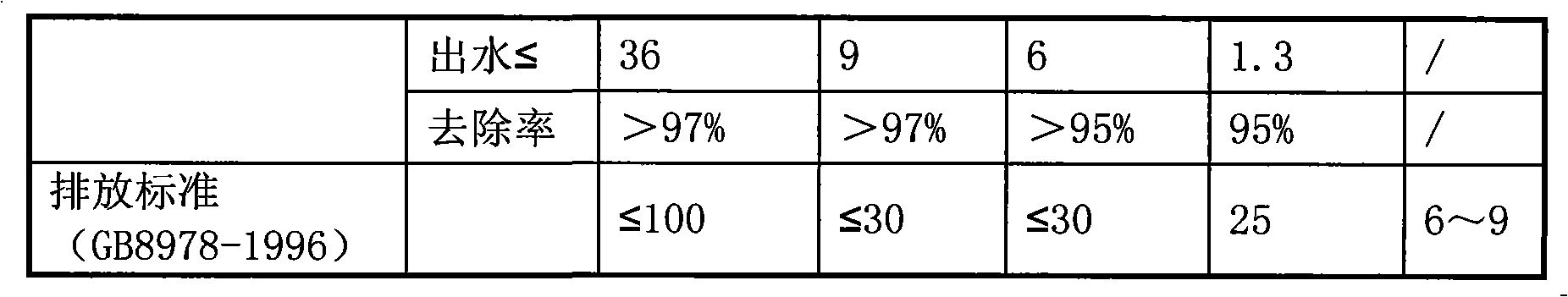

[0029] 2. ...

Embodiment 2

[0044] The high-ammonia-nitrogen sewage produced by a textile printing and dyeing factory adopts the method of the present invention, and the total water volume designed to be treated is 400t / d, and it is designed to operate continuously for 24 hours every day; the influent flow rate of the membrane treatment unit is 16.6m 3 / h; the type of humus in the filler used in the preparation of activated sludge in this example is SH350, and this type of humus is purchased from Japan Zhaorui Co., Ltd., and the particle size of the silica in the filler is 1 mm to 4 mm.

[0045] 1. Influent water quality

[0046] Table 5 Influent water quality of high ammonia nitrogen sewage (unit: mg / l; pH value is dimensionless)

[0047]

Pollutant index

COD Cr

BOD 5

NH 3 -N

SS

TN

(μS / cm)

pH

Concentration of pollutants

12340

3113

1893

786

2114

18790 ...

Embodiment 3

[0063] The high-ammonia-nitrogen sewage produced by a chemical plant adopts the method of the present invention, and the total water volume designed to be treated is 200t / d, and it is designed to operate continuously for 24 hours a day; the influent flow rate of the membrane treatment unit is 8.3m 3 / h; the type of humus in the filler used in the preparation of activated sludge in this example is SH350, and this type of humus is purchased from Japan Zhaorui Co., Ltd., and the particle size of the silica in the filler is 1 mm to 4 mm.

[0064] 1. Influent water quality

[0065] Table 9 Influent water quality of high ammonia nitrogen sewage (unit: mg / l; pH value is dimensionless)

[0066]

Pollutant index

COD Cr

BOD 5

NH 3 -N

SS

TN

(μS / cm)

pH

Concentration of pollutants

24603

4756

3378

634

3667

19800

6~7

[0067]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com