Facility vegetable land soil amendment using magnesite tailings and preparation method thereof

A technology for soil conditioner and magnesite tailings, which is applied to the field of soil conditioner in facility vegetable fields and its preparation, can solve problems such as affecting sustainable utilization, and achieves prevention of nitrate leaching and migration, prevention and control of soil-borne diseases, and environmental reduction. The effect of pollution

Inactive Publication Date: 2010-07-21

SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

View PDF2 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The object of the present invention is to provide a soil conditioner for facility vegetable fields using magnesite tailings and a preparation method thereof, which is a simple process, sufficient raw materials, low cost, and obvious improvement effect using magnesite tailings powder, lime A method for making a soil conditioner for facility vegetable fields with nitrogen and zeolite powder as the main raw materials, which is used to prevent and control soil acidification and salinization in facility vegetable fields, and solve the problem that the facility vegetable fields affect their sustainable use due to the decline in soil quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Mix 92 kg of magnesite powder, 4 kg of lime nitrogen, and 4 kg of zeolite powder, stir thoroughly, and mix evenly to make a soil conditioner.

Embodiment 2-7

[0024] The difference from Example 1 is that the ratio of raw materials is different (see Table 1), and the preparation method is the same as in Example 1.

[0025] Table 1

[0026] Numbering

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

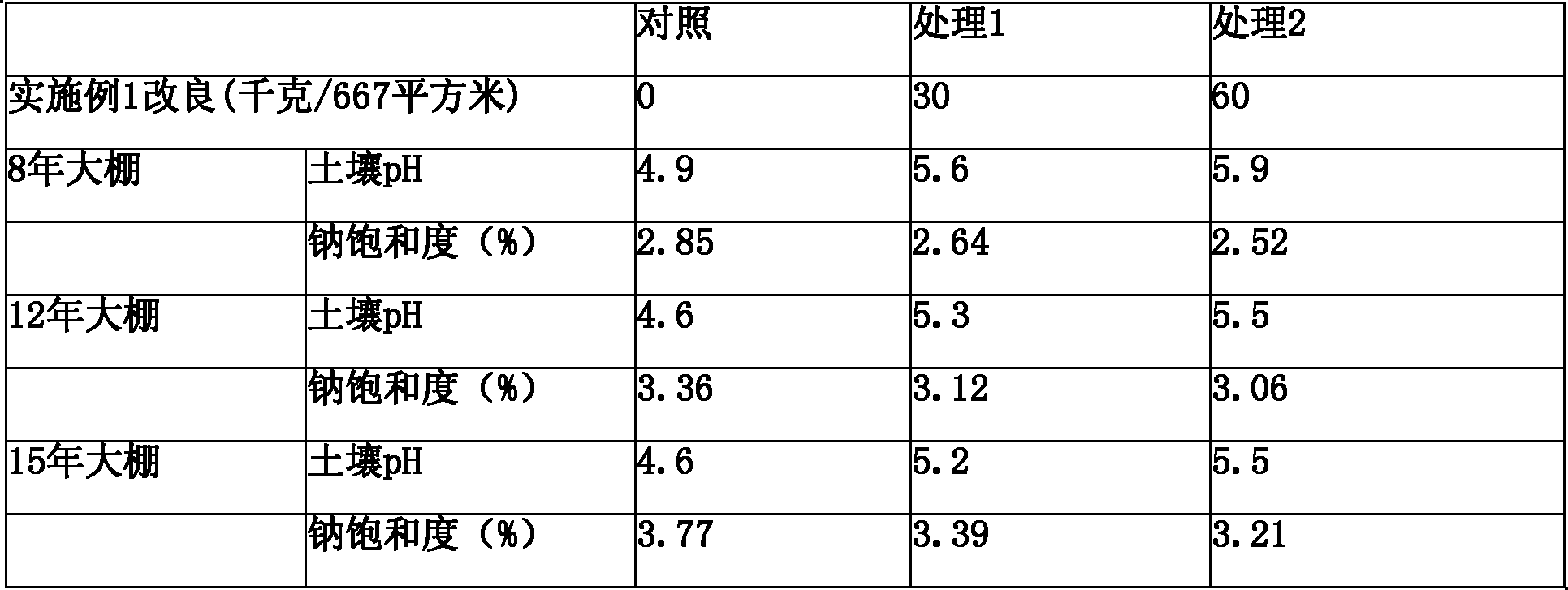

The invention relates to a soil amendment, in particular to a facility vegetable land soil amendment using magnesite tailings and a preparation method thereof, which solve the problems of soil acidification, salinization and the like on the facility vegetable land. The soil amendment comprises the following materials in percentage by weight: 90-95% of magnesite powder, 2-5% of lime nitrogen and 2-5% of zeolite powder. The preparation method of the soil amendment comprises the following steps: grinding the magnesite tailings into magnesite powder sieved by a 40-meshed sieve; and mixing the magnesite powder with powdery or granular lime nitrogen and the zeolite powder sieved by a 60-meshed sieve, and stirring fully until evenly blending, thus obtaining the soil amendment. The preparation method of the invention is simple and pollution-free, which can obviously improve the soil acidity and alkalinity environment of the facility vegetable land, and reduce exchangeable sodium saturation of the soil, and meanwhile has the effect of improving physical properties of the soil.

Description

technical field [0001] The invention relates to a soil improver, in particular to a soil improver for facility vegetable fields using magnesite tailings and a preparation method thereof. Background technique [0002] The main component of magnesite is magnesium carbonate (MgCO 3 ). Natural magnesite also contains calcium, iron, manganese, silicon and other mixed substances. Among the magnesite reserves in China, primary and secondary products containing MgO ≥ 43% account for 53% of the total reserves, of which 1.17 billion tons of magnesite reserves are above 1.17 billion tons, accounting for 37.58% of the total reserves, and secondary product reserves 480 million tons, accounting for 15.42% of the total reserves. In the process of magnesite mining, the first is to screen super-grade or first-grade rich ore, and the third-grade magnesite tailings are mostly thrown away as waste. In mining operations, about 30% of magnesite ore powder and granules are discarded (currently...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K17/04C09K109/00C09K101/00

Inventor 姜勇张玉革陈欣

Owner SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com