Simple method for preparing hydroxyapatite nanocrystals

A technology of hydroxyapatite and nanocrystals, which is applied in the field of material chemistry, can solve the problems of unfavorable industrial production, reduced product purity, and increased production cost, and achieve the effects of fast reaction, high product purity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] (1) Add 0.04mol calcium nitrate to 250ml water and stir quickly to dissolve to obtain Ca 2+ solution;

[0018] (2) will contain 0.027mol PO 4 3- Pour 110mL of ammonia water-potassium dihydrogen phosphate buffer system (pH=7) into the prepared 250ml of calcium nitrate solution, and stir at 200 rpm for 72 hours at 10°C at 1 atmospheric pressure;

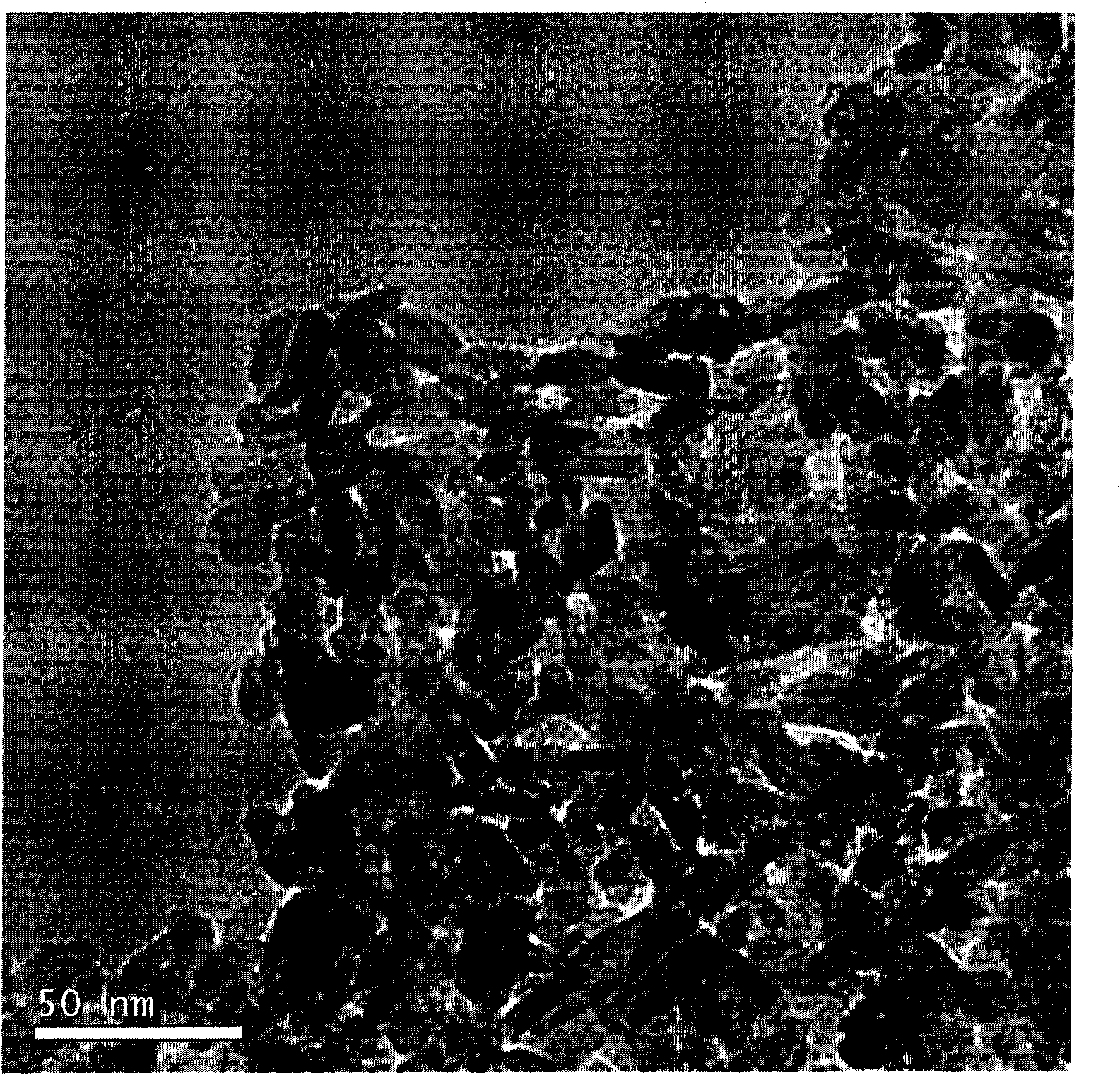

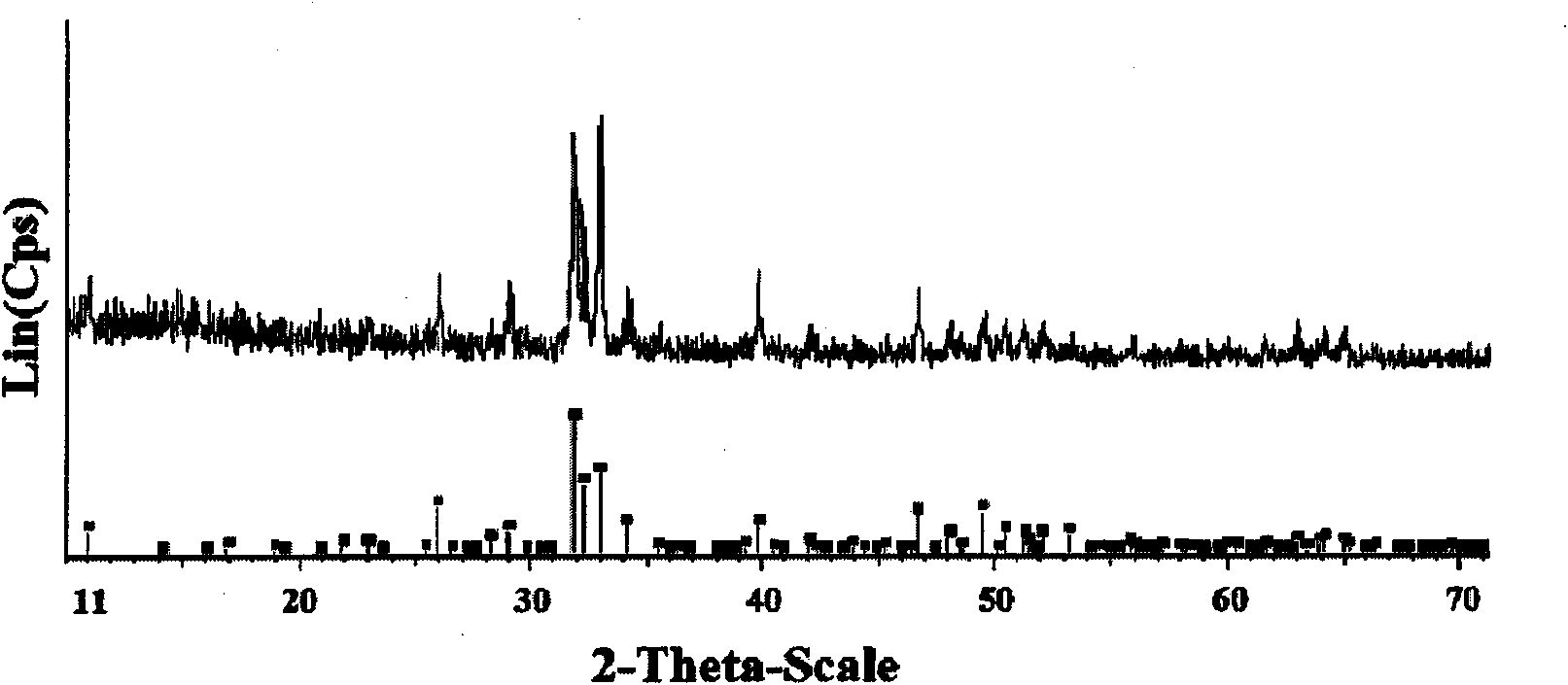

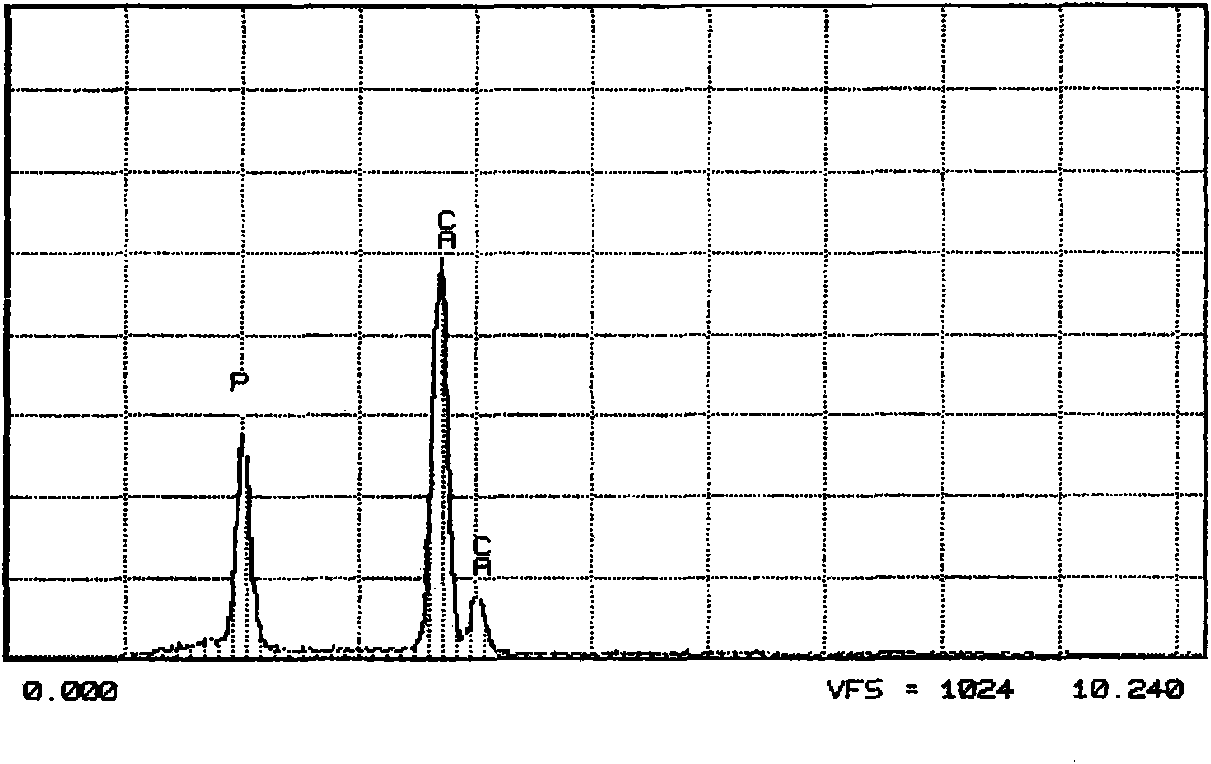

[0019] (3) The product was separated by suction filtration and dried. The transmission electron microscope photo of the obtained hydroxyapatite nanocrystals is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

Embodiment approach 2

[0021] (1) Add 0.045mol calcium nitrate to 250ml water and stir rapidly to dissolve Ca 2+ solution;

[0022] (2) will contain 0.030mol PO 4 3- 110mL ammonia water-ammonium dihydrogen phosphate buffer system (pH=11) was poured into the prepared 250ml calcium nitrate solution, and stirred at 800 rpm for 48 hours at 1 atmosphere pressure and 25°C;

[0023] (3) The product was separated by suction filtration and dried. The transmission electron microscope photo of the obtained hydroxyapatite nanocrystals is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

Embodiment approach 3

[0025] (1) Add 0.9mol calcium nitrate to 500ml water and stir quickly to dissolve Ca 2+ solution;

[0026] (2) will contain 0.6mol PO 4 3- Pour 1500mL of ammonia water-diammonium hydrogen phosphate buffer system (pH=14) into the prepared 500ml calcium nitrate solution, and stir at 1400 rpm for 24 hours at 40°C under 1 atmosphere pressure;

[0027] (3) The product was separated by suction filtration and dried. The transmission electron microscope photo of the obtained hydroxyapatite nanocrystals is shown in figure 1 , X-ray diffraction pattern see figure 2 , and the EDS energy spectrum see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com