Method for extracting oligo proanthocyanidin from grape seeds

A technology of proanthocyanidins and grape seeds, applied in the direction of organic chemistry, which can solve the problems of high equipment investment cost, complex equipment pressure, high risk, etc., and achieve the effects of saving extraction time, reducing energy consumption, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

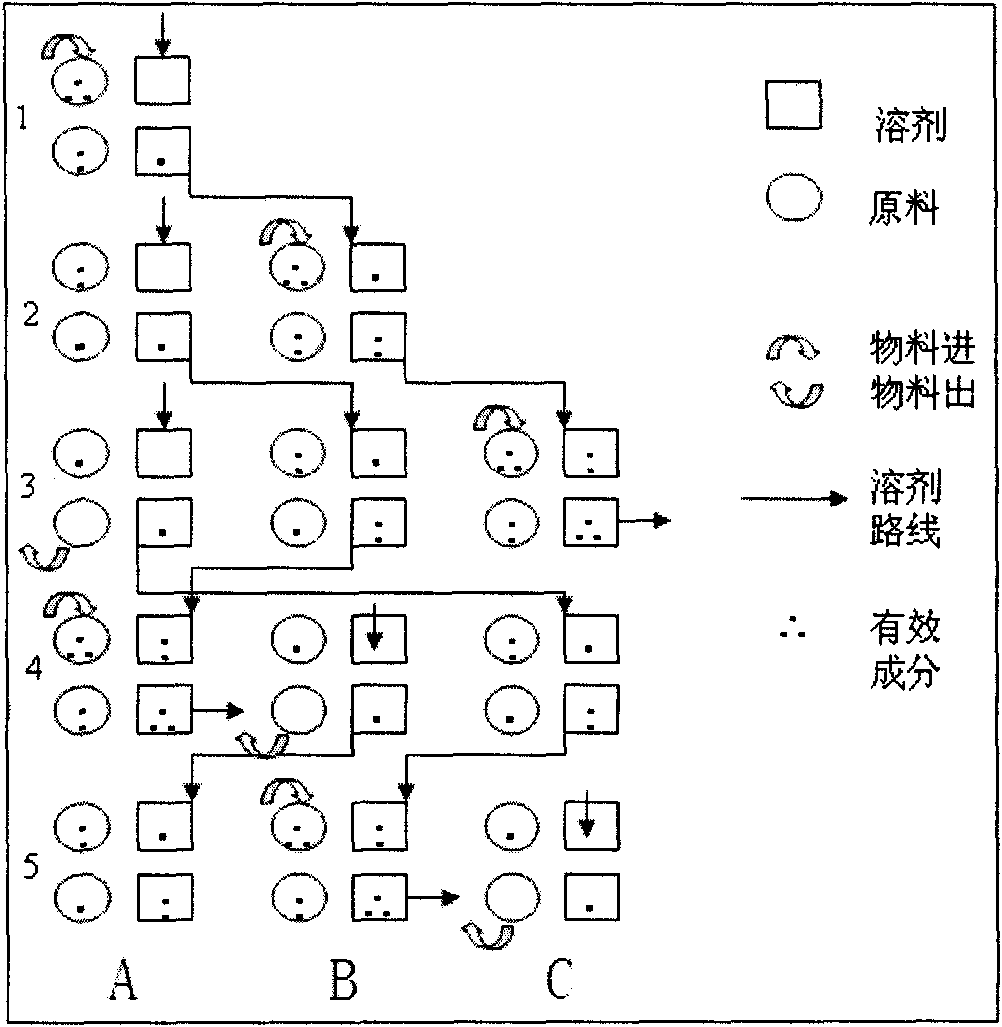

[0016] Ethanol extraction weigh a certain amount of grape seeds crushed to 10-40 mesh, put them into tank A and add 6-10 times the amount of 35-75% ethanol, the extraction temperature is 45-75°C, and the extraction time is 30-60min. Follow the steps below (see figure 1 ), (the left 1-5 in the figure corresponds to the following steps 1-5), the same amount of materials put in each step, the same concentration of ethanol and the same volume, the extraction temperature and time are also the same, measured by the sulfuric acid-vanillin method The proanthocyanidin content and total phenol content measured by Folin-Shuca method (the same below), the extraction transfer rate is 60-95%. ( figure 1 1-5 on the left side correspond to the following steps 1-5 respectively)

[0017] Step 1. Put a certain amount of grape seeds into tanks A, B, and C; add new solvent to tank A and extract at a set temperature. After the extraction is complete, transfer the extract to tank B;

[0018] Step 2. Add...

Embodiment 2

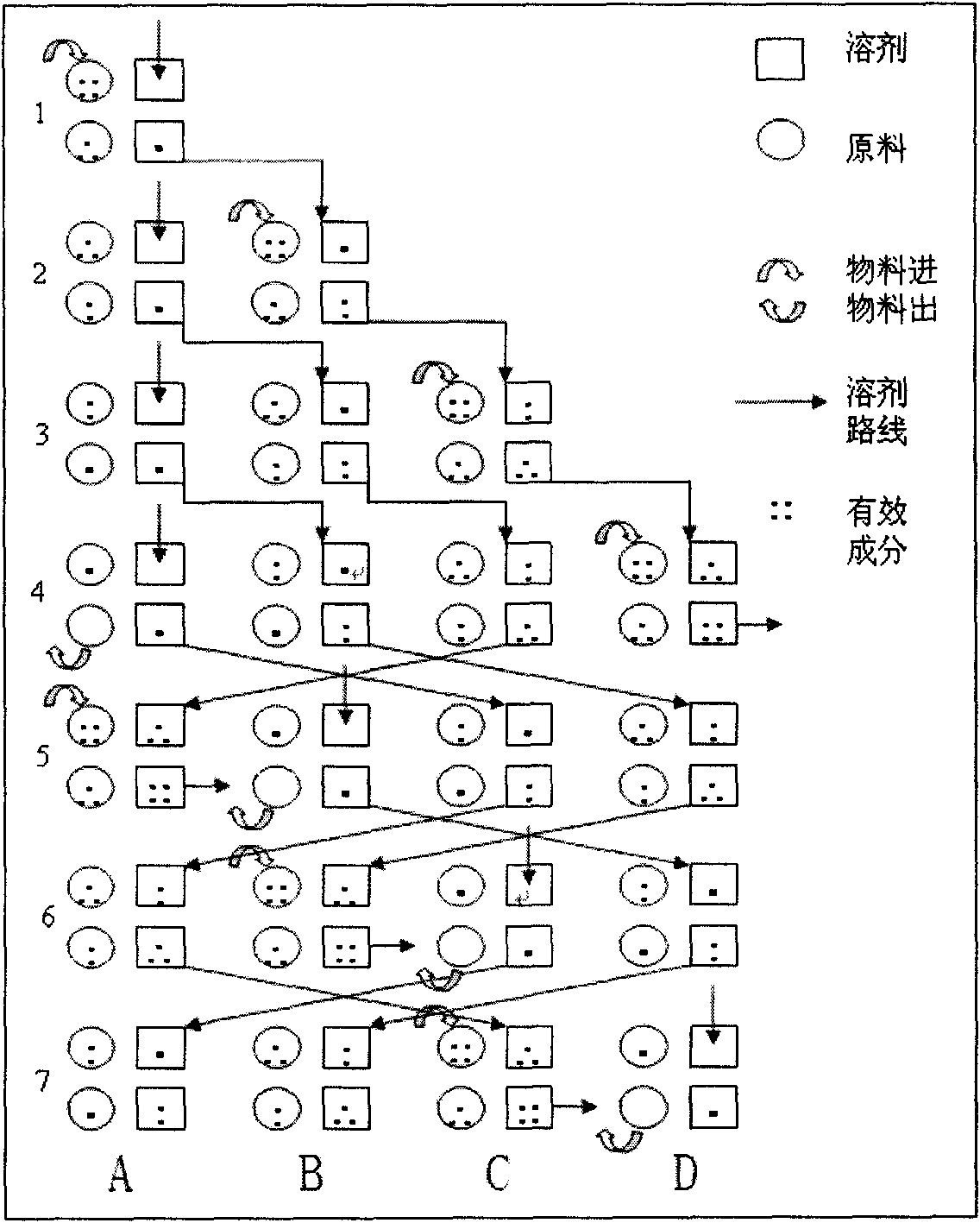

[0024] Water extraction Weigh a certain amount of whole grape seeds into tank A and add 3-6 times the amount of water. The extraction temperature is 70-100°C and the extraction time is 30-60min. Follow the steps below (see figure 2 ), the same amount of materials and the same volume of water are put in each step, the extraction temperature and time are the same, and the extraction transfer rate is 60-85%. ( figure 2 1-7 on the left side correspond to the following steps 1-7 respectively)

[0025] Step 1. Put a certain amount of grape seeds into tanks A, B, C, and D; add new solvent to tank A and extract at a set temperature. After the extraction is complete, transfer the extract to tank B;

[0026] Step 2. Add new solvent to tank A and extract at the set temperature at the same time as tank B; after extraction is completed, the extract from tank B is delivered to tank C, and the extract from tank A is delivered to tank B;

[0027] Step 3. Add new solvent to tank A, and extract A...

Embodiment 3

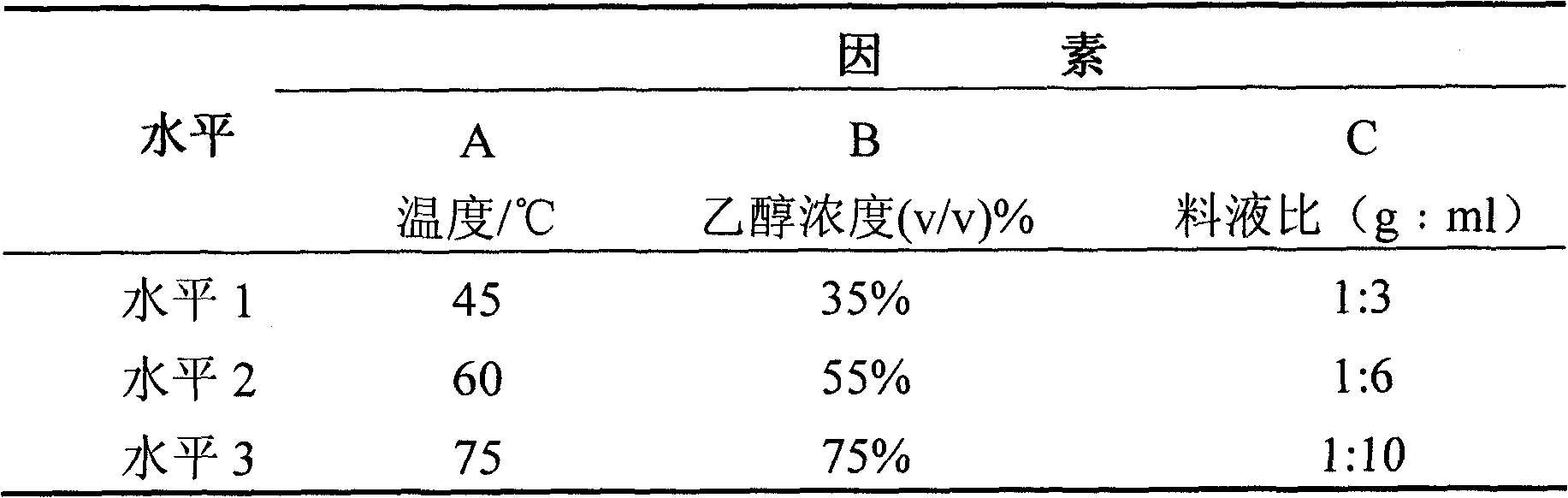

[0034] Accurately weigh several portions of 20 mesh grape seeds, each portion is 20 g, the material-liquid ratio is 1:3 to 1:10 (g:ml), the extraction solvent is 35-75% ethanol, and each extraction time is 30 minutes. Design an orthogonal experiment, see Table 1 for factor levels, and extract from 1-5 according to the operation steps of Example 1. After the extraction, the extracts of steps 3, 4, and 5 are combined, the volume is measured, and the content of proanthocyanidins is sampled and analyzed. The results are shown in Table 2. The preferred specific embodiments should be understood to be illustrative only and not to limit the scope of the present invention in any way.

[0035] Table 1 Factor level table

[0036]

[0037] Table 2 Orthogonal test results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com