Optical time domain reflection (OTDR) distributed optical fiber sensing system based on Brillouin scattering and subsurface temperature monitoring method using same

A technology of optical time domain reflection and distributed optical fiber, which is applied in the direction of thermometer, thermometer, measurement, etc. with physical/chemical changes, can solve the problems of low sensitivity, poor corrosion resistance, poor stability, etc., and achieves high test accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

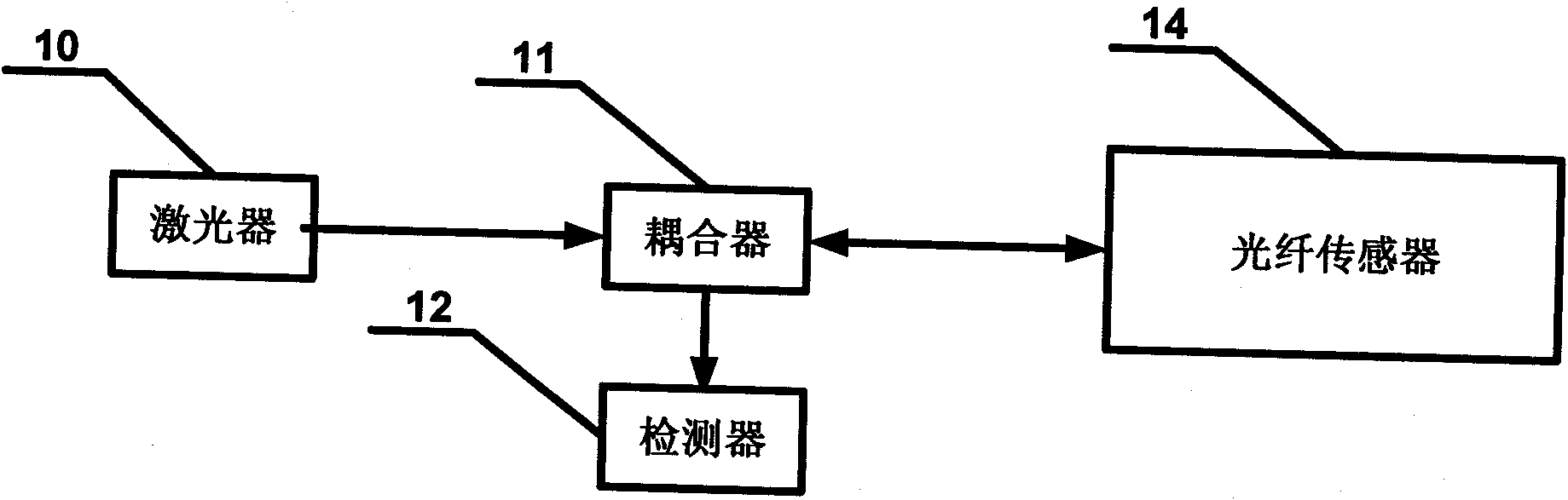

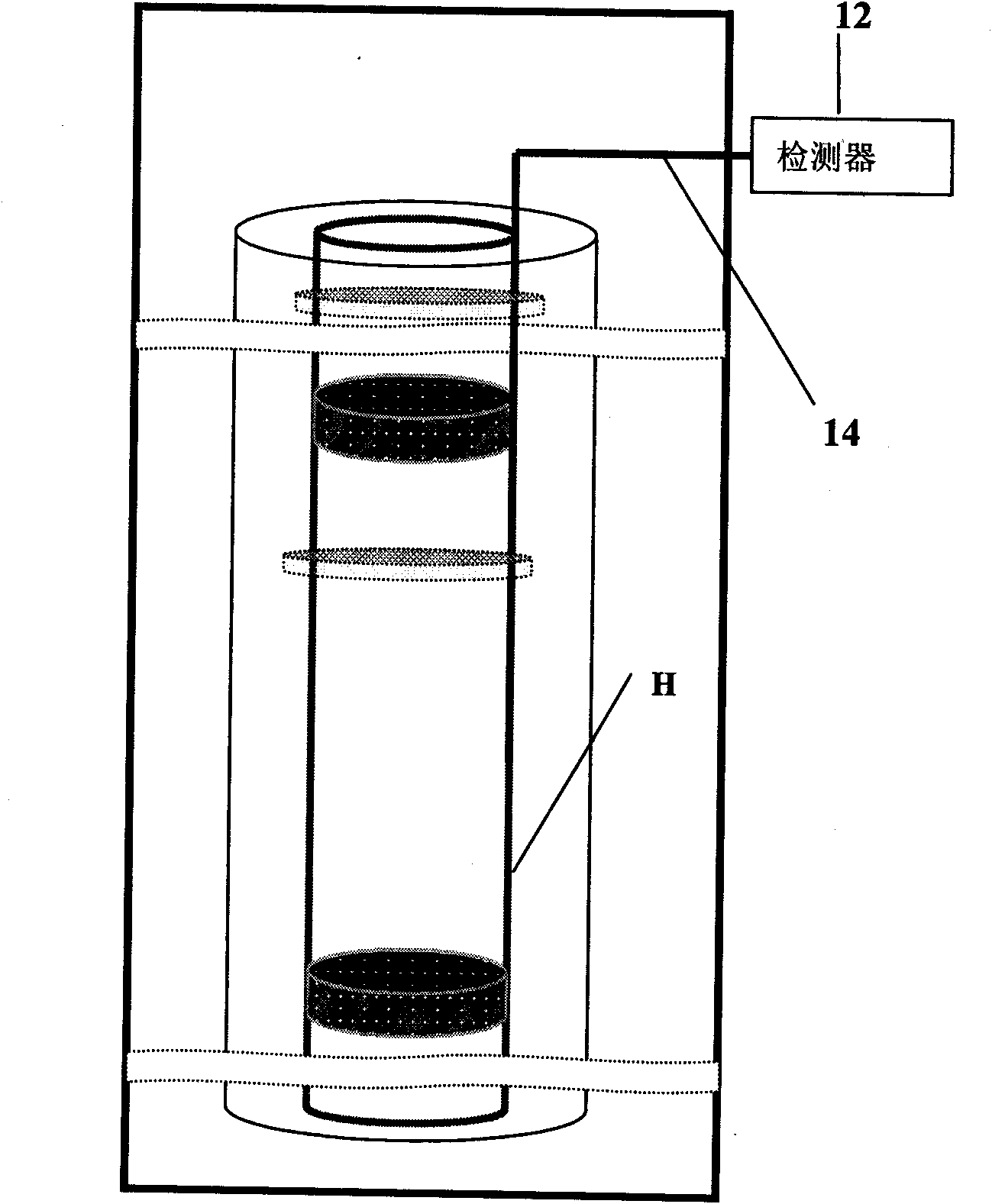

[0022] Specific implementation mode one: combine figure 1 Describe this embodiment, a distributed optical fiber sensing system based on Brillouin scattered light time domain reflection, which includes a laser 10, a coupler 11, a detector 12 and an optical fiber sensor 14, and the laser 10 outputs a beam to the coupler 11 Signal input end, the input / output end of described coupler 11 is connected with one end of optical fiber sensor 14, the optical signal output end of described coupler 11 is connected with the signal input end of detector 12, and the other end of optical fiber sensor 14 is arranged on The outer surface of the oil pipe H is laid in close contact with the oil pipe H.

specific Embodiment approach 2

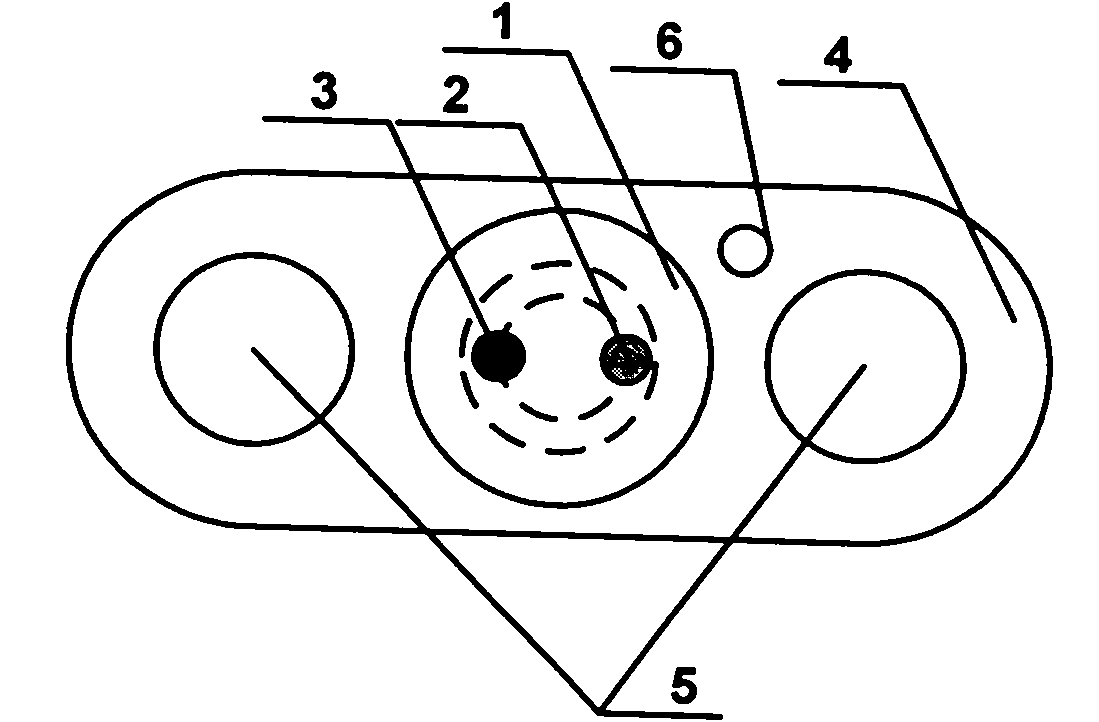

[0023] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is the optical fiber sensor 14, which includes an oil-filled bundle tube 1, an optical fiber 2, and a PE sheath 4. The center of the PE sheath 4 is provided with an oil-filled The bundle tube 1 is provided with an optical fiber 2 at the center of the oil-filled bundle tube 1 , and the optical fiber 2 is arranged along the length direction of the oil-filled bundle tube 1 .

[0024] Oil-filled bundle tube 1 is the plastic tube that the inside is filled with fat-like ointment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 and figure 2 This embodiment is described. The difference between this embodiment and the first or second embodiment is that the optical fiber sensor 14 also includes an FRP reinforcement 5 embedded in the PE sheath 4 and arranged symmetrically. On both sides of the oil-filled bundle tube 1.

[0026] Reinforcements made of fiber reinforced resin (FRP) are arranged on both sides of the oil-filled bundle tube 1 . The oil-filled bundle tube 1 and the FRP reinforcement are encapsulated together with a PE sheath 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com