Method for preparing ceramic thermal storage ball coating phase-change materials

A phase change material, ceramic ball technology, applied in heat storage equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of high manufacturing cost, easy volatility, poor metal corrosion resistance and high temperature resistance, etc. Effects of low manufacturing cost, high heat storage capacity, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

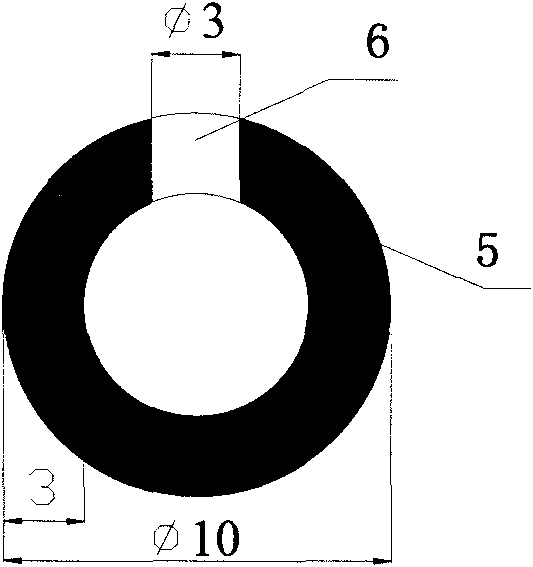

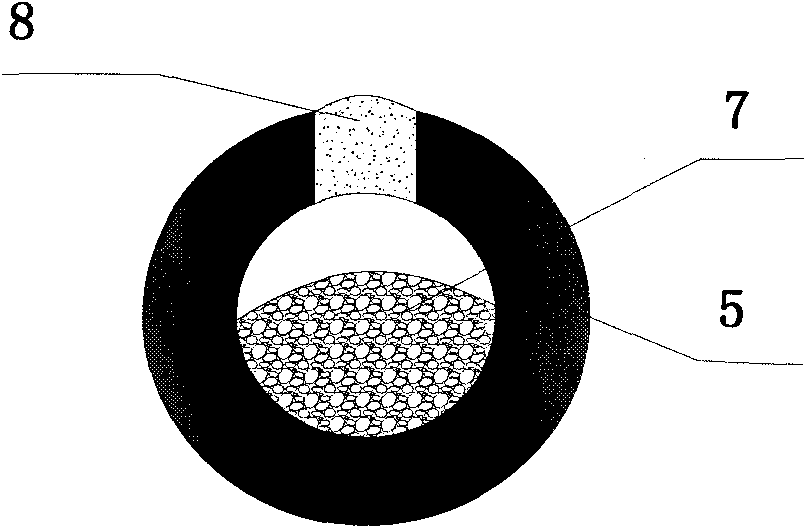

[0028] A method for preparing a ceramic heat storage ball wrapped with a phase change material, comprising the following steps:

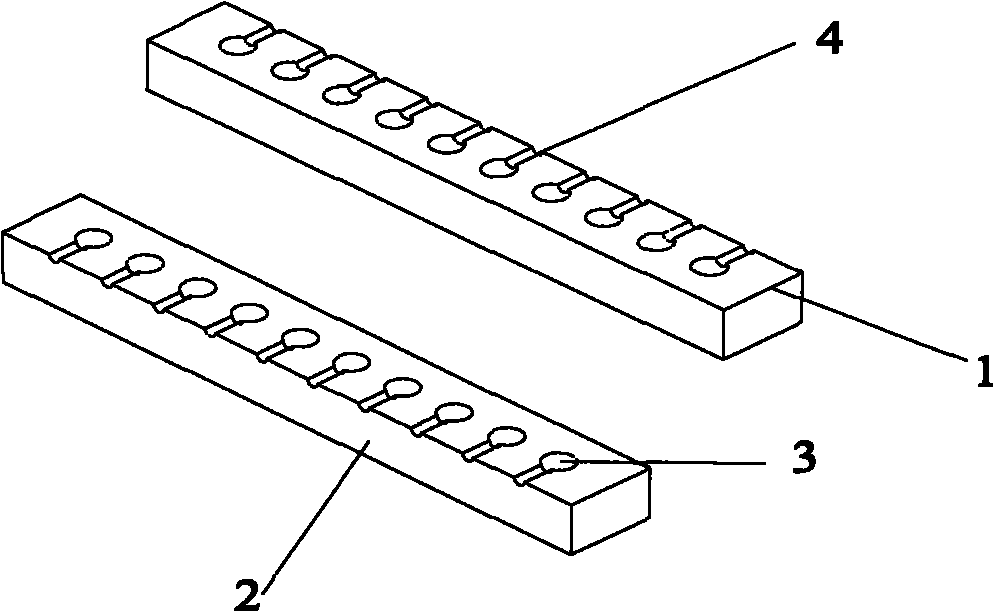

[0029] 1) Preparation of SiC ceramic spherical shell:

[0030] ①Crush SiC and feldspar separately [crushing with a jaw crusher, and then passing through a roller crusher for rollers], then ball milling with a ball mill for 4 hours, passing through a 200-mesh sieve to obtain SiC powder and feldspar powder for later use;

[0031] According to the percentage by weight of each raw material: SiC powder 80%, feldspar powder 8%, kaolin 12%, select SiC powder, feldspar powder and kaolin;

[0032] Put SiC powder, feldspar powder and kaolin into a ball mill and mix for 1 hour to obtain mixture A; add water and polyvinyl alcohol solution to mixture A, and mix with a kneader for 20 minutes to make mud; the amount of water added is 16% of A weight, the add-on of polyvinyl alcohol solution is 6% of compound A weight, wherein the concentration of polyvinyl alcoho...

Embodiment 2

[0052] A method for preparing a ceramic heat storage ball wrapped with a phase change material, comprising the following steps:

[0053] 1) Preparation of SiC ceramic spherical shell:

[0054] ①Crush SiC and feldspar separately [crushing with a jaw crusher, and then passing through a roller crusher for rollers], then ball milling with a ball mill for 4 hours, passing through a 200-mesh sieve to obtain SiC powder and feldspar powder for later use;

[0055] According to the percentage by weight of each raw material: SiC powder 75%, feldspar powder 10%, kaolin 15%, select SiC powder, feldspar powder and kaolin;

[0056] Put SiC powder, feldspar powder and kaolin into a ball mill and mix for 1 hour to obtain mixture A; add water and polyvinyl alcohol solution to mixture A, and mix with a kneader for 20 minutes to make mud; the amount of water added is 15% of A weight, the add-on of polyvinyl alcohol solution is 5% of compound A weight, wherein the concentration of polyvinyl alcoh...

Embodiment 3

[0069] A method for preparing a ceramic heat storage ball wrapped with a phase change material, comprising the following steps:

[0070] 1) Preparation of SiC ceramic spherical shell:

[0071] ①Crush SiC and feldspar separately [crushing with a jaw crusher, and then passing through a roller crusher for rollers], then ball milling with a ball mill for 4 hours, passing through a 200-mesh sieve to obtain SiC powder and feldspar powder for later use;

[0072] According to the percentage by weight of each raw material: SiC powder 85%, feldspar powder 5%, kaolin 10%, select SiC powder, feldspar powder and kaolin;

[0073] Put SiC powder, feldspar powder and kaolin into a ball mill and mix for 1 hour to obtain mixture A; add water and polyvinyl alcohol solution to mixture A, and mix with a kneader for 20 minutes to make mud; the amount of water added is 18% of A weight, the add-on of polyvinyl alcohol solution is 8% of compound A weight, wherein the concentration of polyvinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com