Manufacturing method of wheel center of dehumidification rotating wheel

A manufacturing method and wheel core technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of the limited ability of the runner substrate to absorb moisture, loss of lithium chloride, adverse effects, etc., and achieve strong Dehumidification ability, lasting dehumidification ability, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

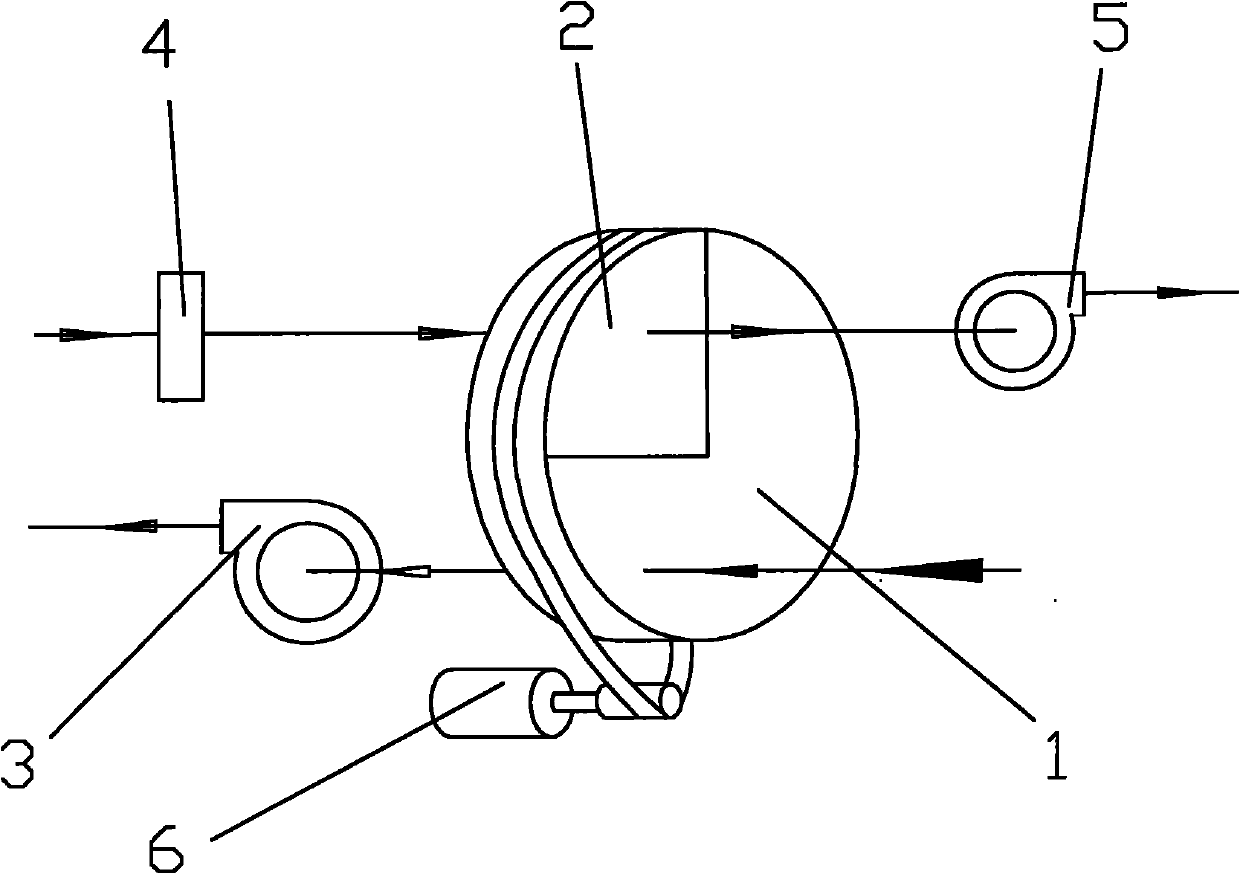

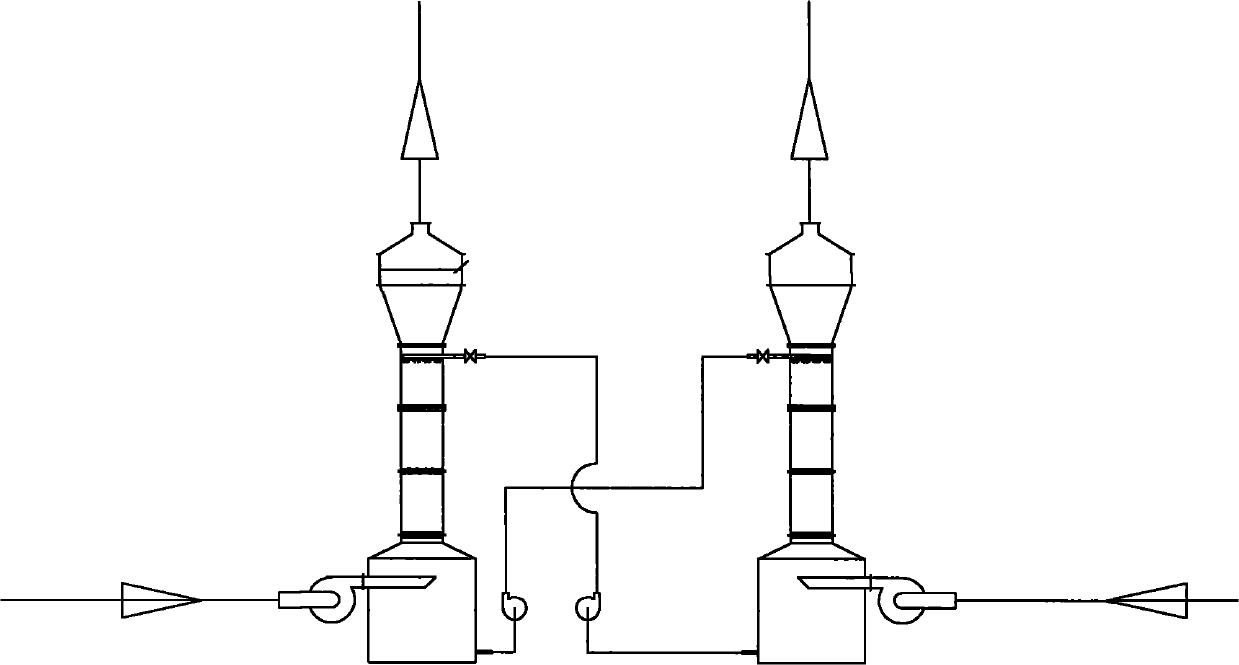

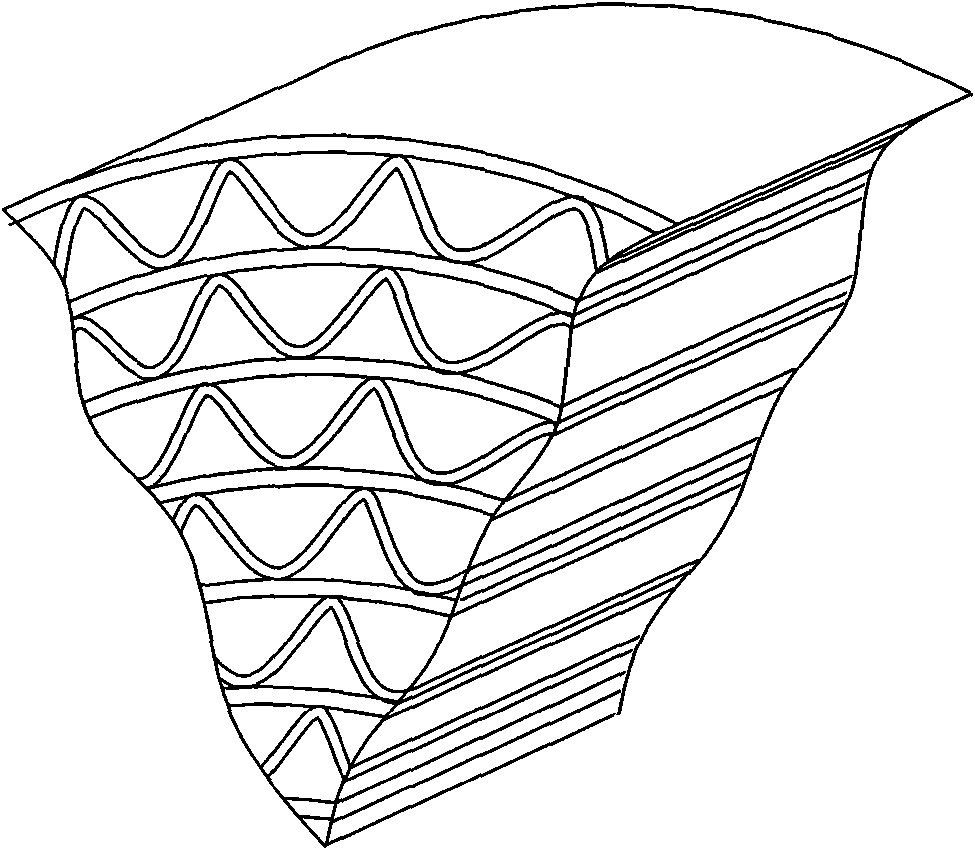

Embodiment 1

[0044] Mix 90 parts by weight of active carbon powder and sepiolite powder with a diameter of 1 μm in any weight ratio, 5 parts by weight of attapulgite and 5 parts by weight of SiO 2 Mix the sol, then mix the resulting mixture with water at a solid content of 20% to form a slurry, and evenly coat the resulting slurry on the glass fiber paper; then heat-press the resulting glass fiber paper to form corrugated glass fiber paper ; Then the corrugated fiberglass paper is rolled or folded into such image 3 and Figure 4 The wheel core shown; next, the obtained wheel core is baked at a temperature of 150°C; the baked wheel core is immersed in a lithium chloride solution with a concentration of 30%, and the infiltration is repeated 3 times until the wheel core When the total solution absorbed reaches 100% of its own weight, it is taken out to obtain the wheel core of the present invention.

Embodiment 2

[0046]Mix 90 parts by weight of macroporous silica gel powder with a diameter of 2 μm and macroporous resin mixed powder, 3 parts by weight of activated clay and 3 parts by weight of water glass, and then mix the resulting mixture with water at a solid content of 30% to form a slurry , the obtained slurry is evenly coated on the activated carbon fiber paper; then the obtained activated carbon fiber paper is hot-pressed to form corrugated activated carbon fiber paper; then the corrugated activated carbon fiber paper is rolled or folded into such image 3 and Figure 4 The wheel core shown; next, the obtained wheel core is baked at 220°C; the baked wheel core is immersed in a lithium chloride solution with a concentration of 45%, and the infiltration is repeated twice until the wheel core When the total solution amount absorbed reaches 130% of its own weight, the wheel core of the present invention can be obtained after taking it out.

Embodiment 3

[0048] Mix 90 parts by weight of activated carbon powder with a diameter of 3 μm, 1 part by weight of lithium magnesium silicate and 1 part by weight of styrene-butadiene rubber, then mix the resulting mixture with water at a solid content of 40% to form a slurry, and coat the resulting slurry evenly On the non-woven fabric; then the resulting non-woven fabric is hot-pressed to form a corrugated non-woven fabric; then the corrugated non-woven fabric is rolled or folded into such a image 3 and Figure 4 The wheel core shown; next, the obtained wheel core is baked at a temperature of 300 ° C; the baked wheel core is infiltrated into a lithium chloride solution with a concentration of 60% and infiltrated once until the wheel core is adsorbed When the total solution amount reaches 150% of its own weight, it is taken out to obtain the wheel core of the present invention.

[0049] The manufacturing method of the wheel core of the dehumidification wheel of the present invention has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com