Robot remote control welding system and method used for remote welding

A remote welding and welding system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high real-time requirements, poor visual feedback of remote welding, poor adaptability of remote welding, etc., to achieve Good adaptability, high real-time requirements, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

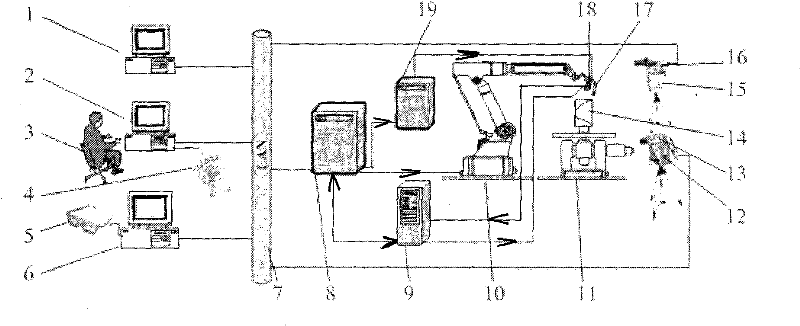

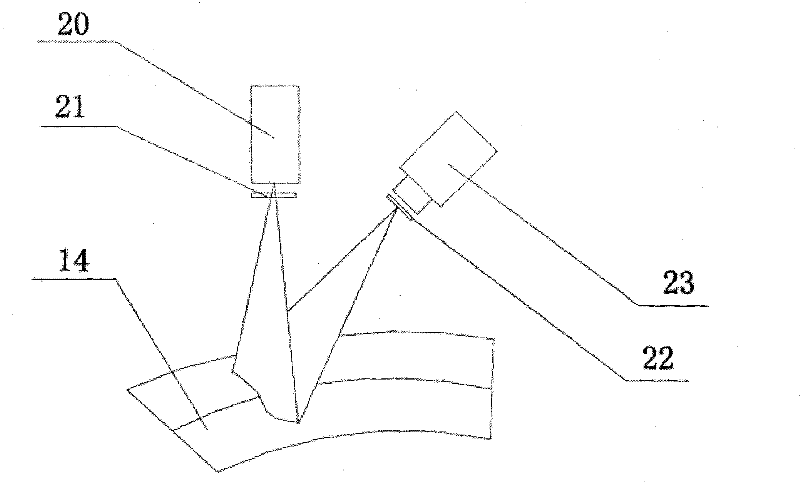

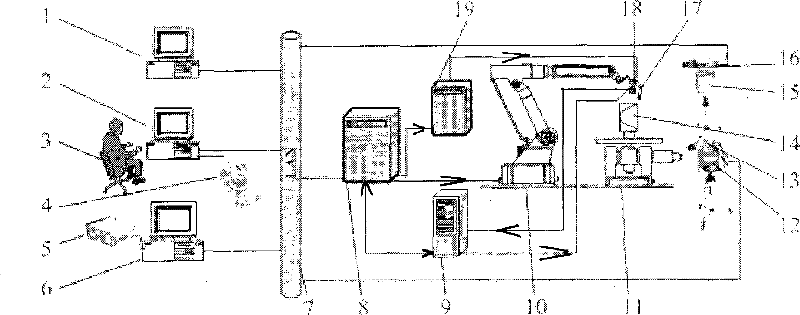

[0011] Specific implementation mode 1: Combination figure 1 with figure 2 To explain this embodiment, the system of this embodiment consists of a macro vision display 1, a central monitoring man-machine interface 2, a spatial mouse 4, liquid crystal shutter glasses 5, a stereo vision display 6, an industrial Ethernet 7, a robot controller 8, and laser vision control. Consisting of the device 9, the robot 10, the working platform 11, the first controllable PTZ 12, the binocular camera 13, the second controllable PTZ 15, the macro zoom camera 16, the welding gun 17, the laser vision sensor working head 18 and the welding power source 19 , The spatial mouse 4 is connected to the central monitoring man-machine interface 2, and the central monitoring man-machine interface 2 is connected to the robot controller 8 through the industrial Ethernet 7, and the liquid crystal shutter glasses 5 are connected to the stereo vision display 6, and The visual display 6 is connected to the binoc...

specific Embodiment approach 2

[0013] Specific implementation manner two: combination figure 1 Describing this embodiment, the robot 10 of this embodiment has six degrees of freedom. The other components and steps are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 To explain this embodiment, the method of this embodiment is completed by the following steps:

[0015] Step 1: The macro zoom camera 16 collects two-dimensional video images, and transmits the two-dimensional video images to the macro vision display 1 through the industrial Ethernet 7, and the operator 3 adjusts the field of view in the central monitoring man-machine interface 2 at the local end;

[0016] Step 2: The operator 3 operates the space mouse 4 and sends out control commands on the central monitoring man-machine interface 2, which are transmitted to the remote robot controller 8 through the industrial Ethernet 7 to control the movement of the remote robot 10, and the robot 10 guides the welding torch 17 The movement reaches 30-40mm above the weld, and the robot controller 8 transmits the pose matrix of the welding torch 17 to the local central monitoring man-machine interface 2 through the industrial Ethernet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com