Metal enclosing guard plate with self-cleaning function

A technology for enclosures and metal substrates, which is applied to metal layered products, roofs using flat/curved panels, building components, etc. Product aesthetics and other issues, to achieve good environmental protection effect, reduce the leakage of harmful substances, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

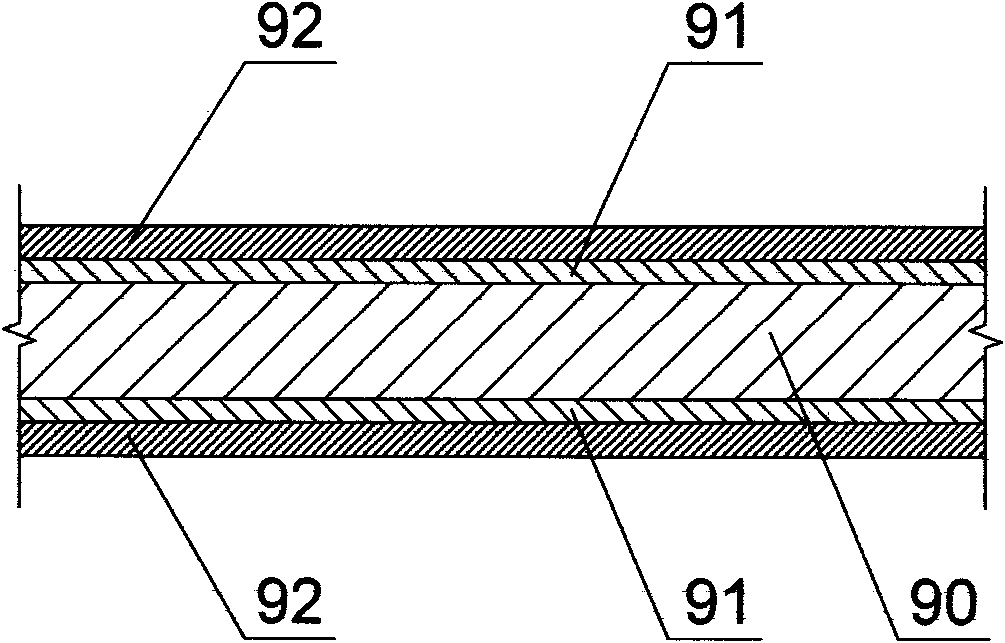

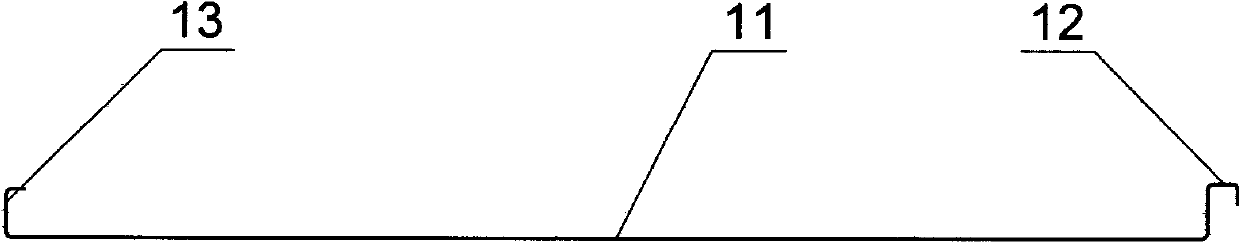

[0054] Such as figure 1 , figure 2 As shown, the metal enclosure with self-cleaning function in this embodiment is a roof panel, and its cross-sectional structure includes a metal substrate 90, the surface of the metal substrate 90 is attached with an inorganic isolation layer 91, and the inorganic isolation A titanium oxide film layer 92 is attached to the surface of the layer 91, and an organic coating is attached to the surface of the metal substrate 90. The metal substrate 90 is an aluminum alloy plate, which has the advantages of light weight and corrosion resistance. The film layer 92 is rich in anatase nano-scale titanium dioxide, with a high concentration of active ingredients. It has strong redox ability, high chemical stability and non-toxic performance under sunlight, and has excellent bactericidal and antibacterial and degrading harmful gas performance. , to avoid the bacteria growling, prevent mildew, avoid the secondary toxicity and irritation and poor persiste...

Embodiment 2

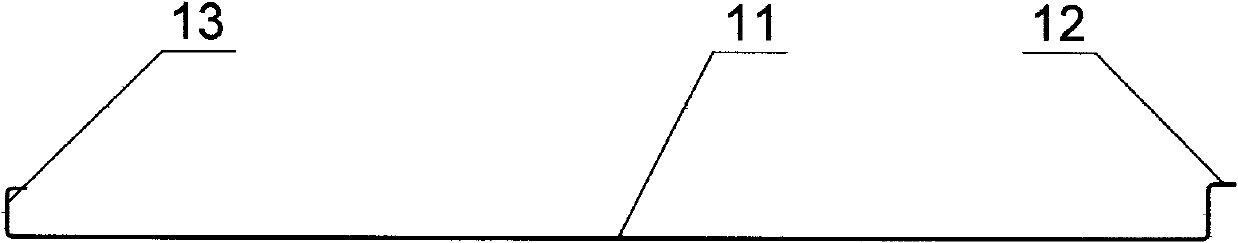

[0056] Such as figure 1 , image 3 As shown, the difference between this embodiment and Embodiment 1 lies in: the shape of the side standing rib 12, in this embodiment, the last bending of the side standing rib 12 is omitted, and the two adjacent The two side standing ribs 12, 13 are welded together between the metal enclosure plates.

[0057] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0059] Such as figure 1 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the shape of the two side standing ribs 12, 13 makes it pass between two adjacent metal enclosure panels The ribs 12 and 13 are matched and buckled together, making the buckling easier and the connection more stable; in addition, in this embodiment, the roof bottom plate 11 is provided with a plurality of corrugated ribs near the two side ribs 12 and 13 Ribs to enhance structural strength and resistance to deformation.

[0060] The remaining features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com