Treatment process of waste mortar in the processing course of silicon crystal

A technology of processing and processing technology, applied in the direction of silicon, silicon compounds, inorganic chemistry, etc., can solve the problems of dependence on imports, high cutting loss rate, etc., and achieve low cost and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

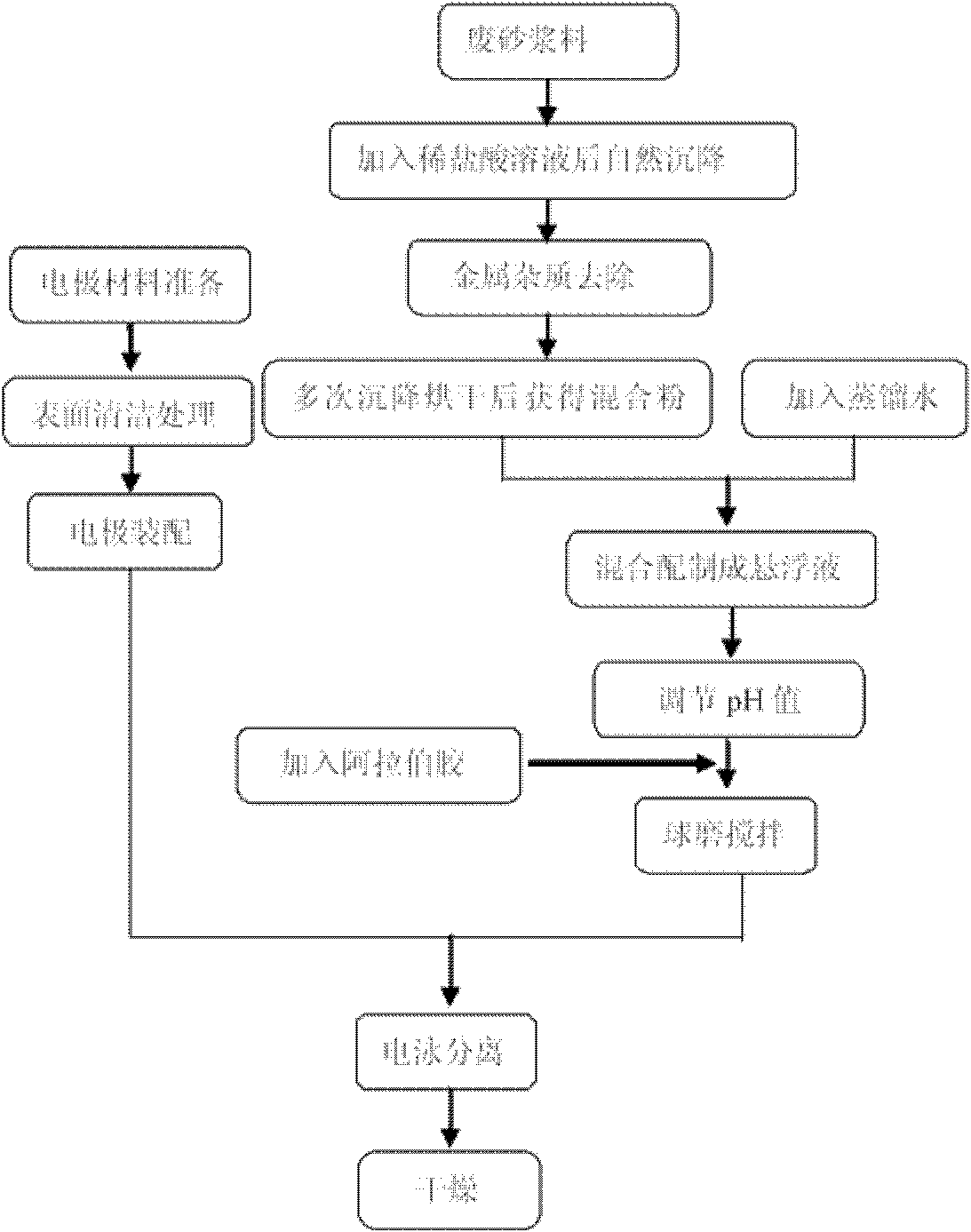

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

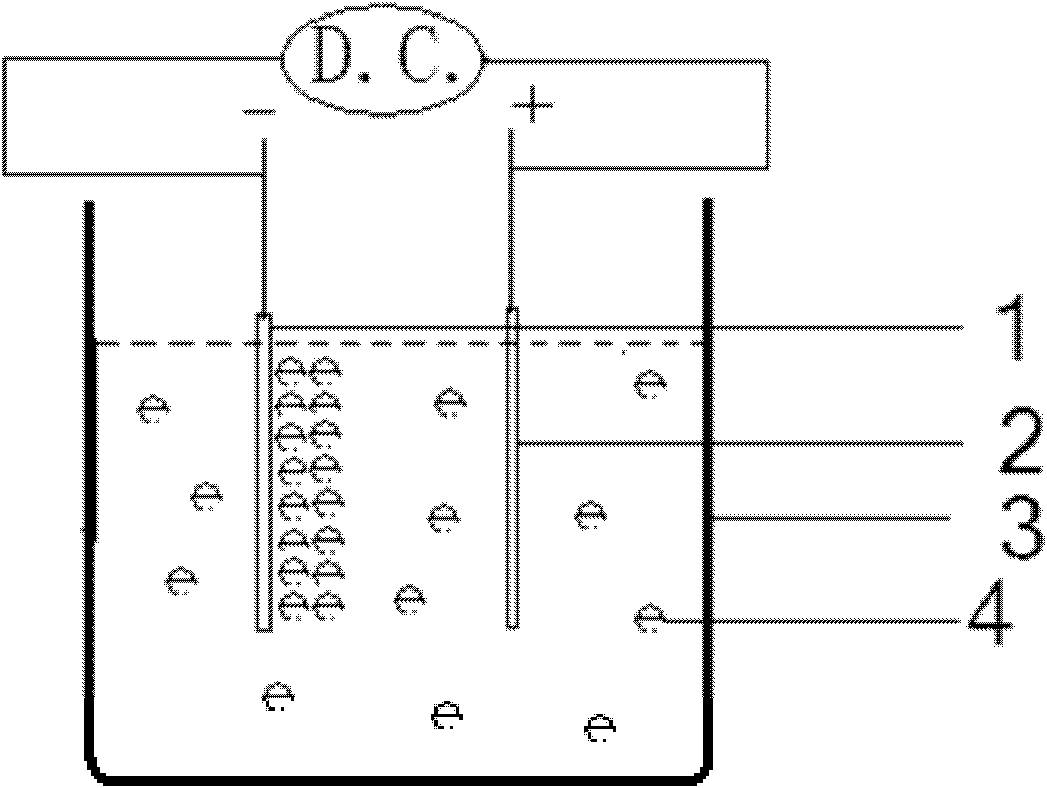

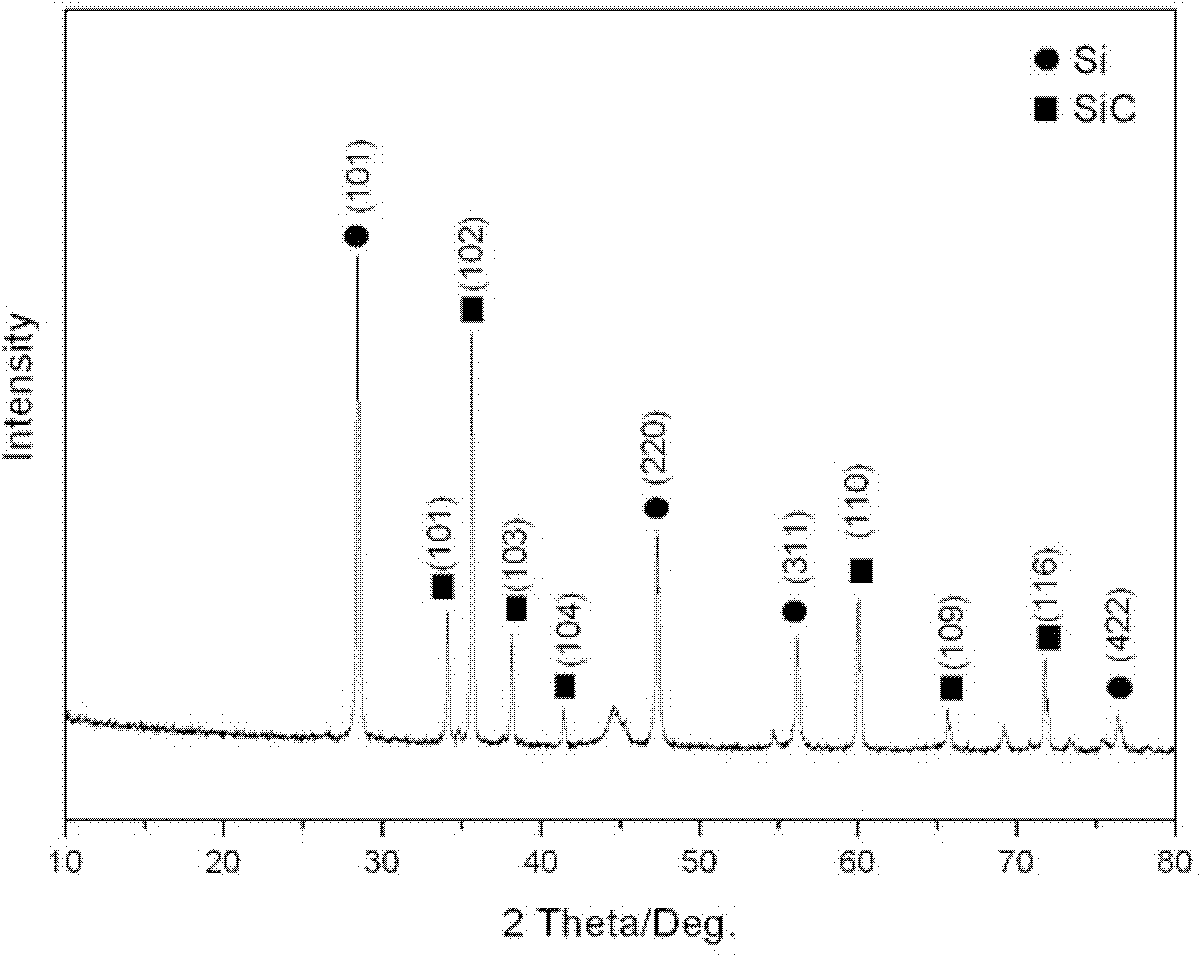

[0013] see figure 1 , adding a volume concentration of 2-5% dilute hydrochloric acid solution to the waste mortar, the volume ratio of the dilute hydrochloric acid solution to the waste mortar is 1.5-3, so that the residual metal fine powder (introduced in the multi-wire cutting process) therein can be removed. After standing and settling at room temperature for 24-48 hours, the upper liquid was discharged. Then add distilled water, repeat sedimentation for 2-4 times and discharge the upper layer liquid to obtain the waste mortar sediment after pickling, and carry out X-ray diffraction (XRD) analysis after drying, the result is as follows image 3 As shown, the XRD results show that there is a certain amount of silicon and silicon carbide in the waste mortar.

[0014] Add 60-80vol.% distilled water to the waste mortar sediment after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com