Particle reinforced foam glass and preparation method thereof

A foam glass and particle-reinforced technology, which is applied in the field of foam glass manufacturing, can solve the problems of low flexural strength, small pore size of foam glass, complicated application procedures, etc., and achieve the effect of wide application range, high mechanical strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

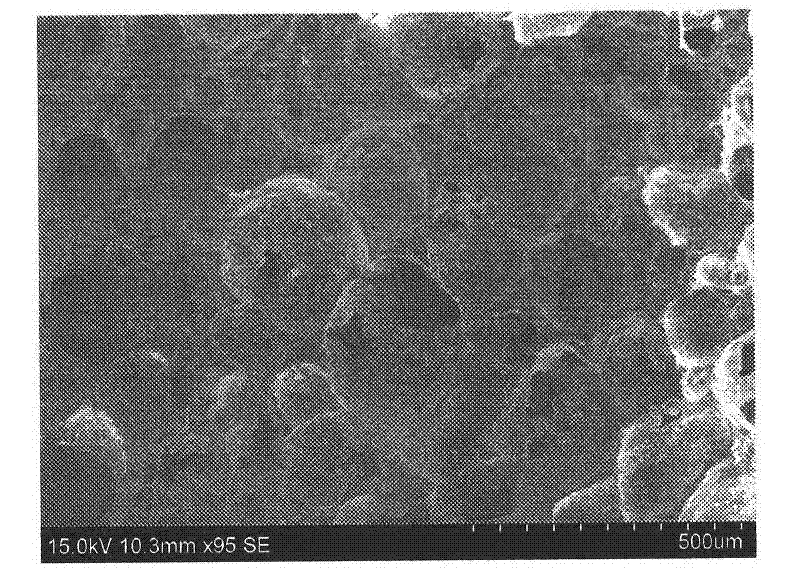

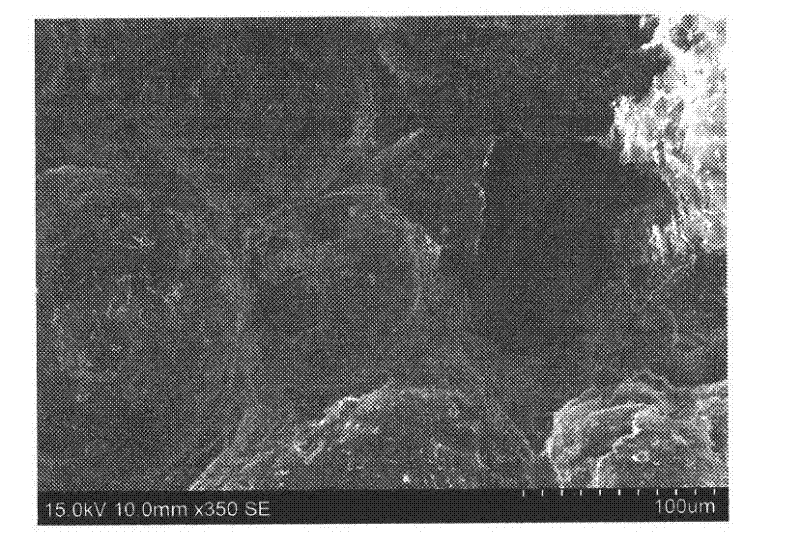

[0017] Embodiment 1, at first waste glass is cleaned up, after drying, ball mill to 280 mesh to get glass powder, by mass fraction 82% glass powder, 10% silicon nitride, 3% carbon powder, 3% sodium nitrate, 1 Add % titanium dioxide and 1% zirconium dioxide into a ball mill jar and mix for 60 minutes to obtain batch materials; After heating up to 800°C at a heating rate of 5°C / min, keep it warm for 60 minutes; then raise the temperature to 900°C at a heating rate of 5°C / min, and hold it for 60 minutes; Cool to below 50°C to get foam glass. The formed foam glass has a uniform structure, and the surface average cell diameter of the sample measured by a reading microscope is 1.3mm; the apparent density of the test is 0.36g cm by the drainage method -3 ; The strength of the test is measured by a universal material testing machine, and the specific strength is 8.53MPa / (g.cm -3 ). see figure 1 , it can be seen that silicon nitride particles are evenly distributed between the bubb...

Embodiment 2

[0018] Embodiment 2, at first waste glass is cleaned up, after drying, ball mill to 280 mesh to get glass powder, by mass fraction 75% glass powder, 15% silicon nitride, 5% carbon powder, 3% sodium nitrate, 1 %titanium dioxide and 1% zirconium dioxide were added to the ball mill tank and mixed for 90 minutes to obtain batch materials; then the batch materials were added to the mold, and the mold was moved into a foaming furnace for firing according to the following process: from room temperature to 12°C After heating up to 800°C at a heating rate of 1 / min, keep the temperature for 30 minutes; then raise the temperature to 950°C at a heating rate of 4°C / min, and keep it for 80 minutes; Cool to below 50°C to get foam glass. The formed foam glass has a uniform structure, and the surface average cell diameter of the sample measured by a reading microscope is 2.3mm; the apparent density of the test is 0.31g cm by the drainage method -3; The strength of the test is measured by a un...

Embodiment 3

[0019] Embodiment 3, at first waste glass is cleaned up, ball milled to 280 orders after drying to obtain glass powder, by mass fraction 70% glass powder, 20% silicon nitride, 5% carbon powder, 3% sodium nitrate, 1 %titanium dioxide and 1% zirconium dioxide were added to the ball mill tank and mixed for 30 minutes to obtain the batch materials; then the batch materials were added to the mold, and the mold was moved into the foaming furnace for firing according to the following process: from room temperature to 9°C After heating up to 800°C at a heating rate of 1 / min, keep the temperature for 90 minutes; then raise the temperature to 980°C at a heating rate of 9°C / min, and keep it for 90 minutes; Cool to below 50°C to get foam glass. The formed foam glass has a uniform structure, and the surface average cell diameter of the sample measured by a reading microscope is 1.7 mm; the apparent density of the test is 0.51 g cm by the drainage method -3 ; The strength of the test is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com