Novel antistatic bending-resisting polypropylene dustproof fan blade and preparation method thereof

A polypropylene and antistatic technology, which is applied in the field of preparation of the antistatic and anti-bending polypropylene dust-proof fan blades, can solve the problems of short antistatic life, oil spots, and inability to completely discharge gas, and achieve excellent The effect of antistatic performance, good impact resistance and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

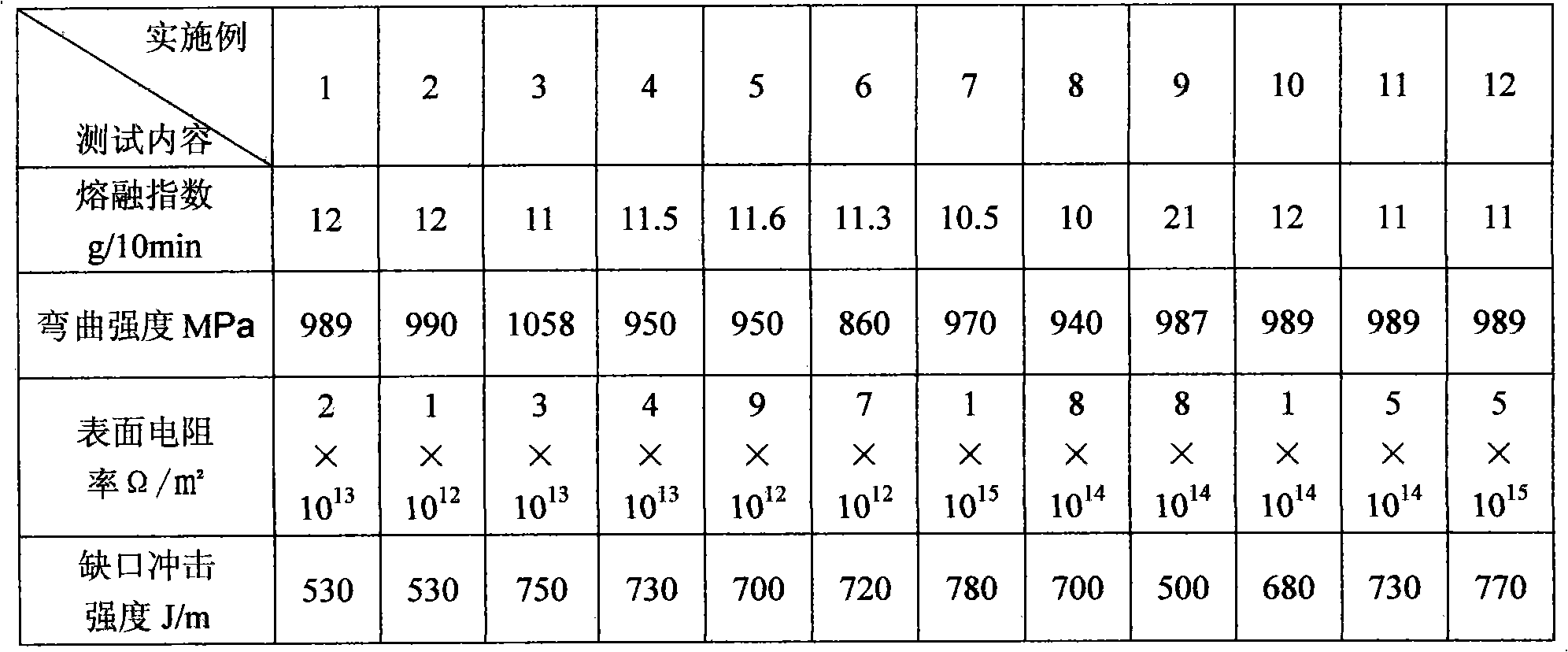

Examples

Embodiment 1

[0033] The dust-proof fan blade of the present invention is made of a novel antistatic and anti-bending polypropylene material, wherein the new anti-static and anti-bending polypropylene material is made of the following components in percentage by weight: 56.5% homopolymer Polypropylene, 0.5% glyceryl monostearate (Glycerylmonostearate), 1% dodecyl-2 (2-hydroxyethyl) amine (N, N-Bis (2-hydroxyethyl) dodecanamide), 32% 300-500 mm long, glass fiber filaments with a single filament diameter of 10-20 microns, 10% gypsum powder with a fineness of 5-40 microns.

[0034] Put the above-mentioned components into the high mixer in proportion, mix and stir evenly, and knead through a twin-screw extruder (the diameter of the twin-screw extruder used is 39mm, and the length-to-diameter ratio is 35. Equipped with a 2kg measuring range Loss-in-weight feeder), extruded at 180-285-185-190 degrees Celsius, then pulled, cooled in a water tank, and then granulated. The particle length is 2-3mm. ...

Embodiment 2

[0036] The dust-proof fan blade of the present invention is made of a novel antistatic and anti-bending polypropylene material, wherein the new anti-static and anti-bending polypropylene material is made of the following components in percentage by weight: 60.5% homopolymer Polypropylene, 1.5% sorbitol stearate, 1% dodecyl-2(2-hydroxyethyl)amine (N,N-Bis(2-hydroxyethyl)dodecanamide), 28% 300-500 Millimeter long, glass fiber filaments with a monofilament diameter of 10-20 microns, 8% gypsum powder with a fineness of 5-40 microns, and 1% antioxidant.

[0037] Put the above-mentioned components into the high mixer in proportion, mix and stir evenly, and knead through a twin-screw extruder (the diameter of the twin-screw extruder used is 39mm, and the length-to-diameter ratio is 35. Equipped with a 2kg measuring range Loss-in-weight feeder), extruded at 180-285-185-190 degrees Celsius, then pulled, cooled in a water tank, and then granulated. The particle length is 2-3mm. Dust-pr...

Embodiment 3

[0039]The dust-proof fan blade of the present invention is made of a novel antistatic and anti-bending polypropylene material, wherein the new anti-static and anti-bending polypropylene material is made of the following components in percentage by weight: 57% homopolymer Polypropylene, 1% sorbitol stearate, 1.7% tetraalkyl phosphonium alkylbenzene sulfonate (tetraalkyl phosphonium alkylbenzene sulfonate), 31% 300-500mm long, single filament diameter 10-20 Micron glass fiber filaments, 9% gypsum powder with a fineness of 5-40 microns, and 0.3% UV stabilizer.

[0040] Put the above-mentioned components into the high mixer in proportion, mix and stir evenly, and knead through a twin-screw extruder (the diameter of the twin-screw extruder used is 39mm, and the length-to-diameter ratio is 35. Equipped with a 2kg measuring range Loss-in-weight feeder), extruded at 180-285-185-190 degrees Celsius, then pulled, cooled in a water tank, and then granulated. The particle length is 2-3mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com