Jet control system utilizing air-assisted power to atomize urea reductant

An air-assisted and control system technology, applied in the direction of exhaust devices, engine components, machines/engines, etc., can solve the problems of SCR conversion efficiency drop, blockage, etc., and achieve the effects of easy industrial application, elimination of NOX, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

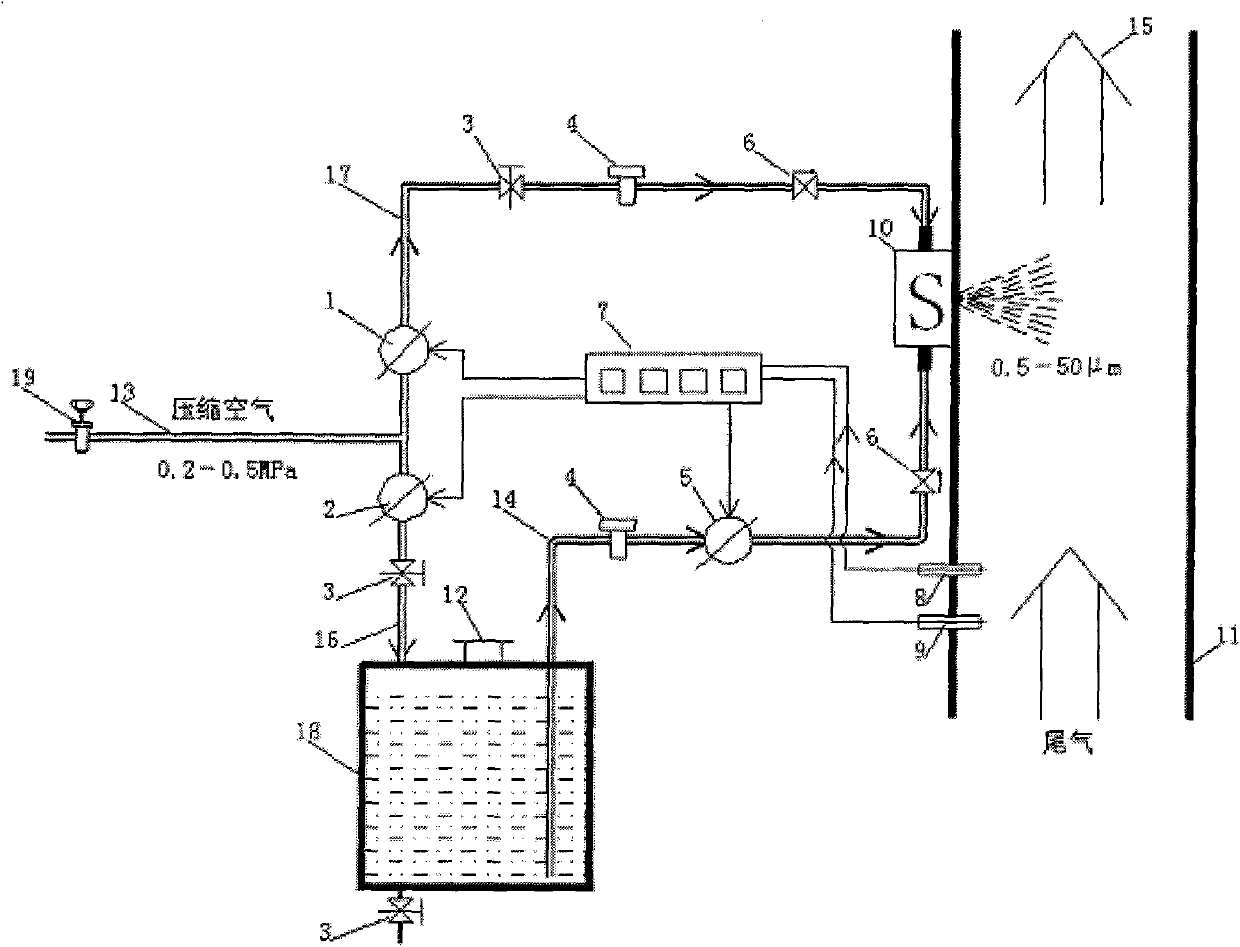

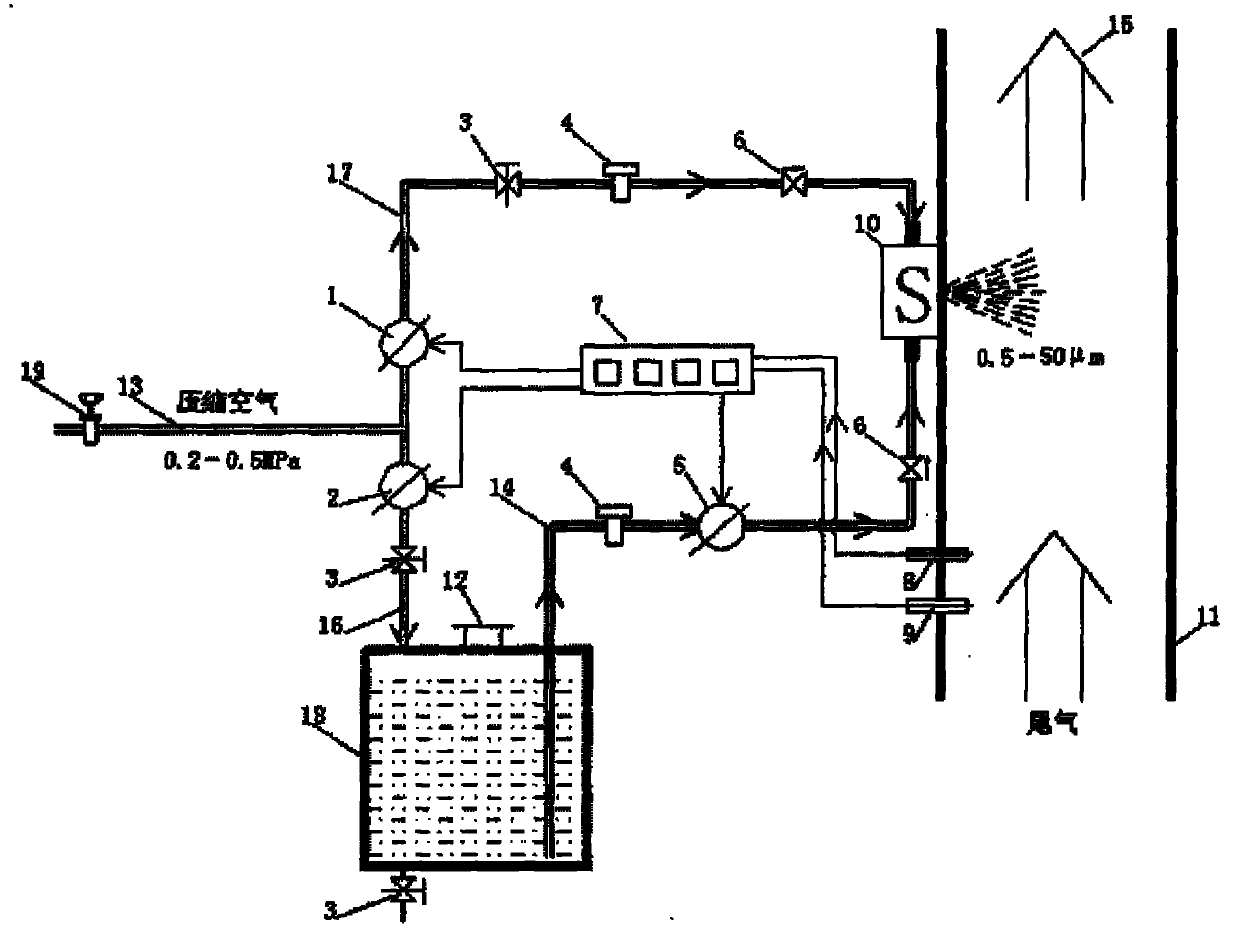

[0024] Use a stainless steel tube or nylon tube with an inner diameter of 10mm as the compressed air main pipe 13. The pressure range of the compressed air main pipe 13 is 0.2Mpa, which is preset by the pressure regulating valve 19. The power source of the compressed air can come from the brake air storage tank on the vehicle; Stainless steel pipes with an inner diameter of 4 mm are used as the urea reducing agent delivery pipe 14, the compressed air branch pipe 16 of the urea reducing agent storage tank and the nozzle atomization compressed air branch pipe 17; adjust the pressure range of the nozzle atomization compressed air branch pipe 17 to 0.1Mpa; adjust the urea reducing agent storage The pressure range of the tank compressed air branch pipe 16 is 0.14Mpa; the opening of the liquid flow solenoid valve 5 is adjusted by the signal output by the control unit 7; the input signal of the control unit 7 comes from the industrial temperature sensor 8; the pressure-resistant urea r...

Embodiment 2

[0026]A nylon tube with an inner diameter of 10mm is used as the compressed air main pipe 13. The pressure range of the compressed air main pipe 13 is 0.5Mpa, which is preset by the pressure regulating valve 19. The power source of the compressed air can come from the vehicle-mounted brake air tank; the inner diameter is 6mm The nylon tube is used as the urea reducing agent delivery pipe 14, the compressed air branch pipe 16 of the urea reducing agent storage tank, and the nozzle atomizing compressed air branch pipe 17; adjust the pressure range of the nozzle atomizing compressed air branch pipe 17 to 0.4Mpa; adjust the compressed air of the urea reducing agent storage tank The pressure range of the branch pipe 16 is 0.46Mpa; the opening degree of the liquid flow solenoid valve 5 is regulated by the signal output by the control unit 7; the input signal of the control unit 7 comes from an industrial temperature sensor 8; the pressure-resistant urea reducing agent container cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com