Vertical gravity conveying enforced cross-flow drying method and device

A drying equipment and gravity technology, applied in drying solid materials, lighting and heating equipment, heating to dry solid materials, etc., can solve problems such as failure to meet high coal output requirements, deterioration or combustion of materials with low ignition points, and easy damage to parts. , to achieve the effect of increasing the drying area through flow, less exhaust dust and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

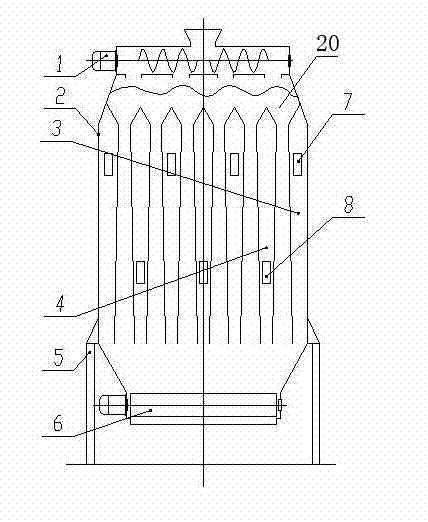

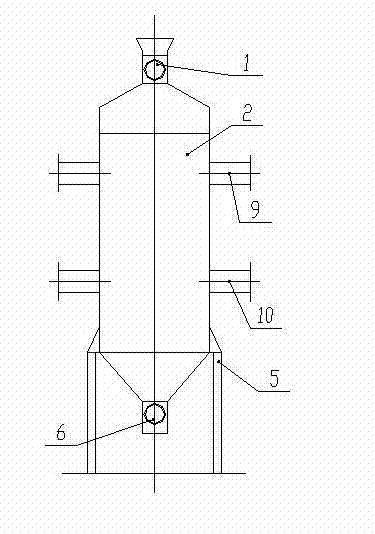

[0058] Refer to attached figure 1 , 2 , Vertical gravity conveying drum forced through-flow drying equipment includes left and right spiral distributor 1, drying bin body 2, negative pressure chamber 3, positive pressure chamber 4, frame 5, impeller unloader 6, air outlet 7, air inlet 8. Exhaust air main pipe 9, air inlet main pipe 10, wherein the dry warehouse body 2 is a steel square warehouse structure with a rectangular cross section and a heat insulation layer around it, and its upper and lower parts are respectively closed inward; the positive pressure chamber 4 and the negative pressure chamber Multiple groups of pressure chambers 3 are vertically arranged in the straight section of the drying chamber body 2, and are equal in width to the drying chamber body 2. There is a certain interval between the two chambers, and the vertical section of the interval space is an isosceles trapezoid with a small top and a large bottom; The air inlet main pipe 10 and the exhaust air ...

Embodiment 2

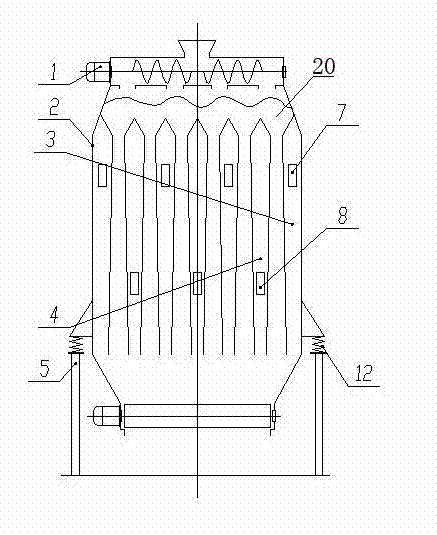

[0060] Refer to attached image 3 , 4 In this embodiment, the drying bin 2 is vibrated by the vibrating device 11, which is used to improve the vertical sinking of the material, activate the material, and increase the ability of the air flow to penetrate the material.

[0061] The difference from Embodiment 1 is that the shock-absorbing base 12 is installed on the frame 5, the drying bin body 2 is installed on the shock-absorbing base 12, and the drying bin body 2 is attached with a vibrating device 11, which can be such as electromagnetic Vibrators, mechanical vibrators, warehouse wall vibrators, vibration motors, etc. The shock absorber can be installed on the shock absorbing base by seat type or suspension type.

Embodiment 3

[0063] Refer to attached Figure 8 , in the third embodiment, three unloaders can be set according to the width of the bin body to reduce the closing angle of the lower part of the bin body and ensure that the sinking speed of the materials in the same cross-section in the drying bin body is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com