High-pressure transducer testing system

A high-voltage frequency converter and test system technology, which is applied in the direction of instruments, measuring electronics, and measuring devices, can solve problems such as unsafe test efficiency and low efficiency, and achieve the effects of improving test efficiency, reducing energy consumption, and ensuring test safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

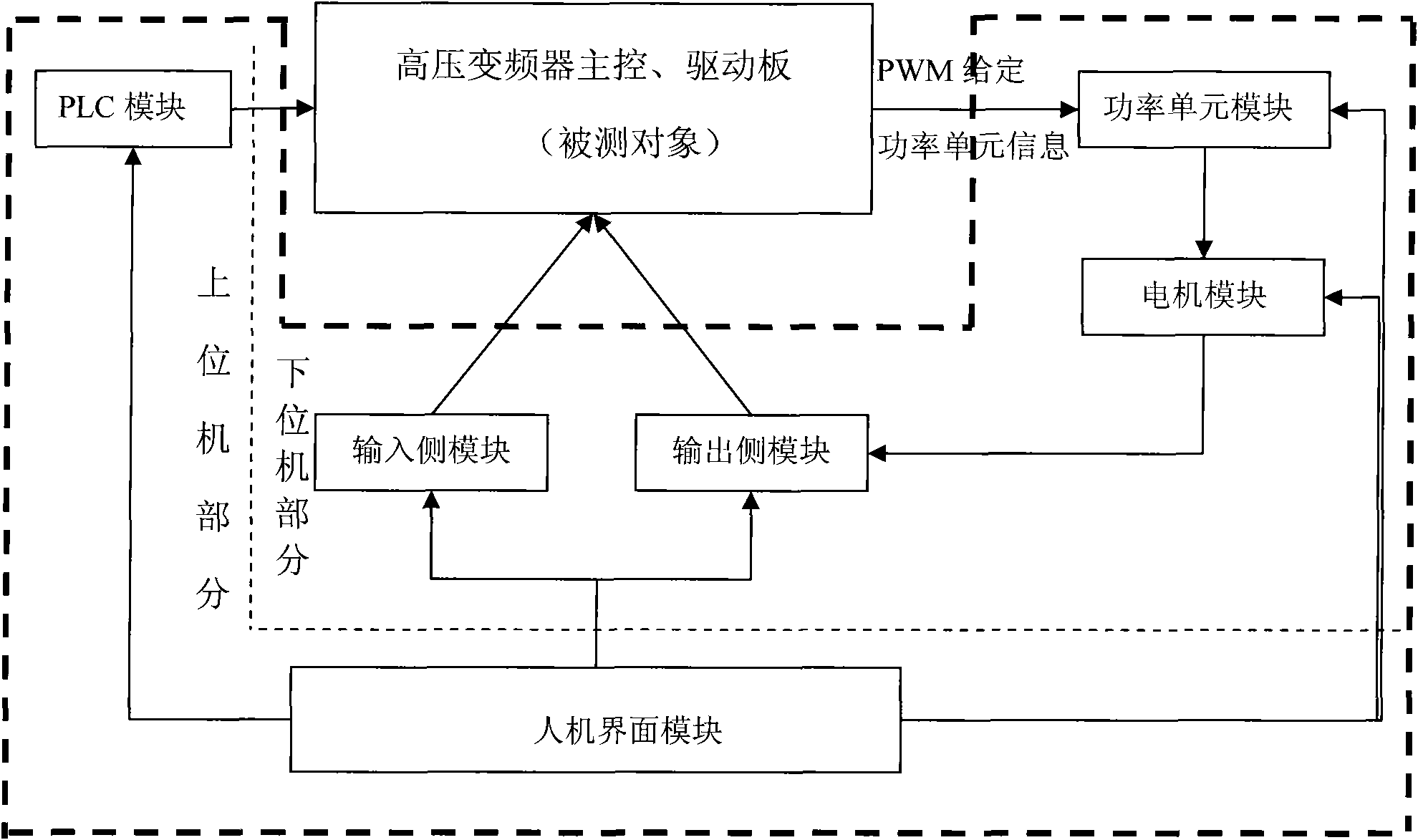

Method used

Image

Examples

Embodiment 1

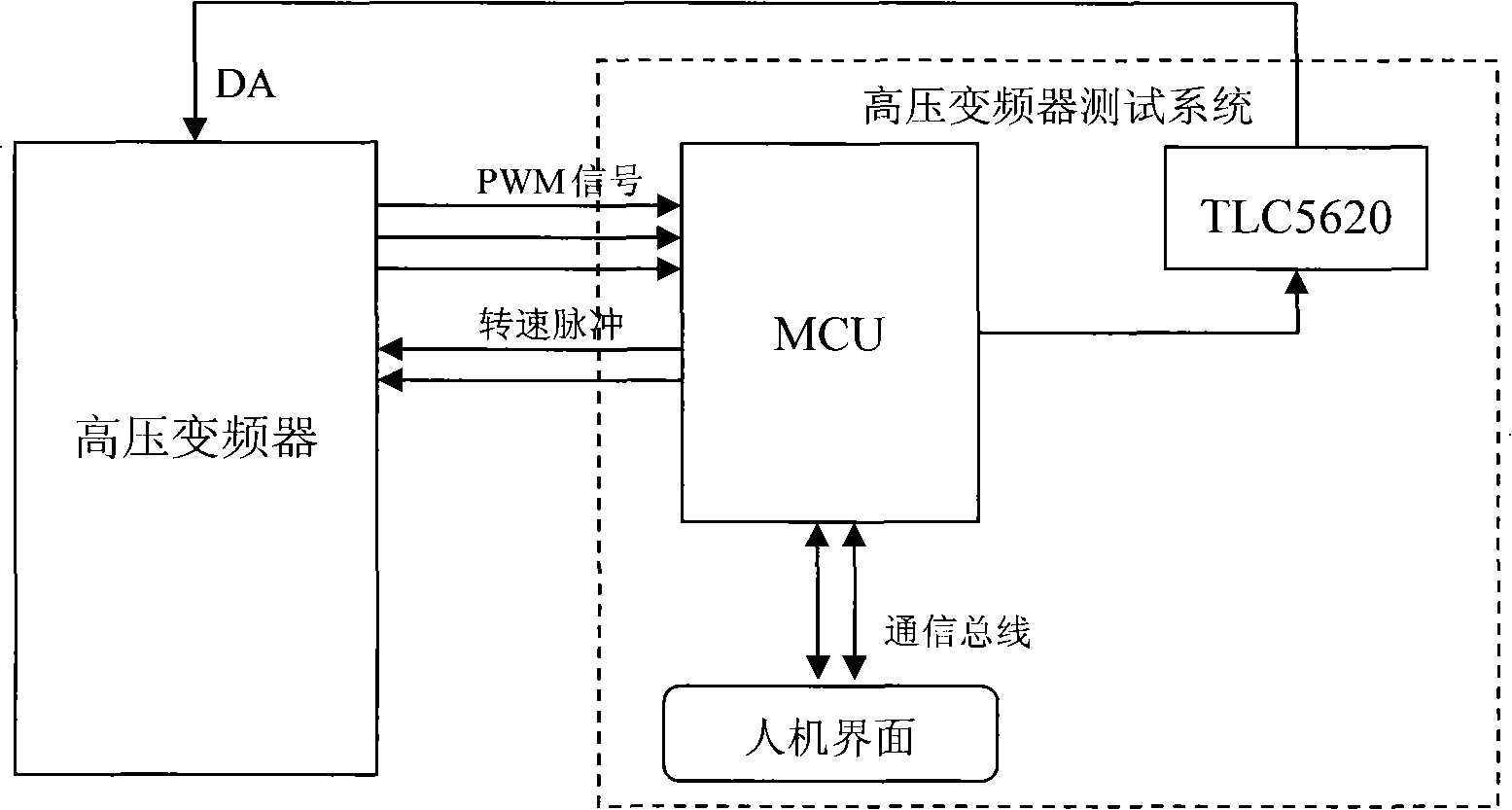

[0039] Such as figure 2 Shown is a high-voltage inverter test system based on MCU chips. In this embodiment, a high-performance MCU chip (STM32F103VB type) is selected to simultaneously realize functions such as PWM detection module, power unit module, motor module, and speed pulse output. Select D / A conversion chip, such as TLC5620 chip, to realize D / A output function. Users can use the man-machine interface to set the status of various peripheral components and system environment parameters through the communication module of the system, and can also simulate various fault sources. The MCU chip detects the PWM wave output by the high-voltage inverter in real time and at high speed through the I / O parallel port interrupt. At the same time, according to the PWM detection result and the motor model parameters, the output voltage, current, speed, torque, power value and other physical quantities can be calculated. Then, by driving the D / A chip, the physical quantities such as vo...

Embodiment 2

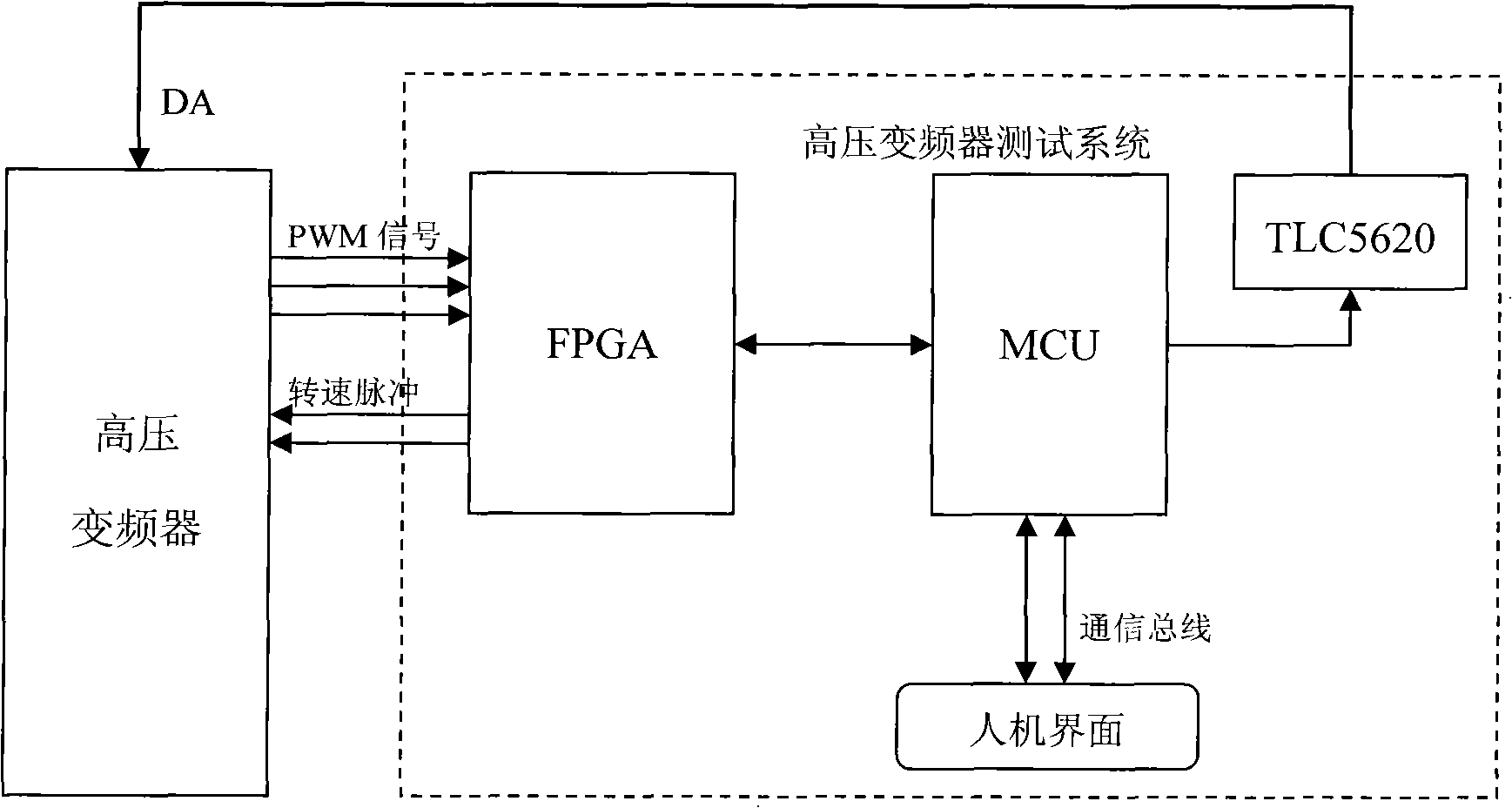

[0041] Such as image 3 Shown is a high-voltage inverter test system based on FPGA+MCU. This embodiment FPGA chip selects the A3P250 type chip of ProASIC3 series, and it realizes PWM wave detection module, power unit module function, promptly is used for being responsible for PWM wave detection, superimposes frequency converter output voltage, and the result of detection and processing passes through I / O parallel port and I 2 The C interface is transmitted to the MCU chip, and the encoder is simulated at the same time, and the real-time speed calculated by the MCU chip is output in the form of pulses. The MCU chip uses STM32F103VB chip, which realizes the function of the motor module, through the I / O parallel port or I 2 The C interface reads the PWM detection and processing results transmitted by the FPGA chip, and calculates the physical quantities such as voltage, current, speed, torque, and power in real time. At the same time, physical quantities such as voltage and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com