Monolithic catalyst for simultaneously removing formaldehyde, carbon monoxide and ozone at room temperature

A carbon monoxide and catalyst technology, which is applied in the preparation of the above-mentioned catalysts, the above-mentioned catalysts, and the field of monolithic catalysts, can solve the problems of poor moisture resistance, etc., and achieve the effects of strong moisture resistance, large processing capacity, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Lattice doped titanium α-MnO 2 Prepared by redox method. Add a certain proportion of manganese sulfate and titanium sulfate into a 500mL flask, and then feed 20mL / min containing 600mg / m 3 Ozone air, at a constant temperature of 90°C for 24h, filtered, washed, dried at 110°C for 12h, and calcined at 500°C for 6h to obtain α-MnO doped with titanium lattice 2 , respectively denoted as "5%Ti-MnO 2 , 10% Ti-MnO 2 , 30% Ti-MnO 2 and 50% Ti-MnO 2 ".

[0027] XRD and HRTEM analysis prove that titanium ions enter into α-MnO 2 lattice.

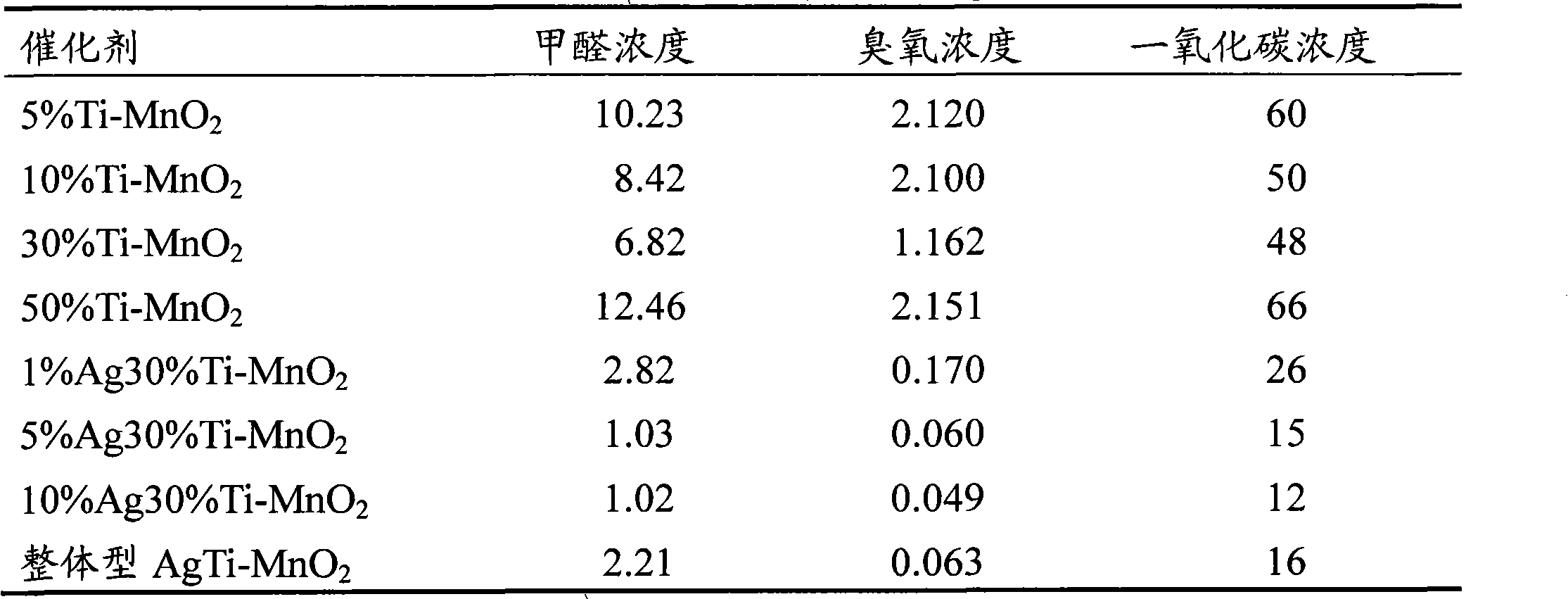

[0028] Catalyst performance tests were carried out in a continuous-flow fixed-bed reactor. Before the catalyst performance test, the catalyst was not treated in any way. The powder catalyst was pressed into tablets and crushed to make 0.25-0.50mm particle samples, and then 0.5g particle samples were placed in a glass tube, at room temperature (20°C) and relative Under the condition of humidity of 50%, pass through containing 0.1~50mg / m ...

Embodiment 2

[0030] α-MnO doped with silver in the channels 2 Prepared by ion exchange method. According to a certain amount of 30%Ti-MnO 2 Add 500mL of different concentrations of AgNO 3 solution, add 10% H 2 o 2 Aqueous solution, then add 25wt% ammonia water, stir and exchange at room temperature for 12h, filter, wash, dry at 110°C for 12h, and then bake at 500°C to obtain lattice-doped titanium and channel-doped silver α-MnO 2 , denoted as 1%Ag30%Ti-MnO 2 , 5%Ag30%Ti-MnO 2 and 10%Ag30%Ti-MnO 2 .

[0031] XRD and HRTEM analysis prove that titanium ions enter into α-MnO 2 Lattice and Ag into α-MnO 2 Pores lead to micro-changes in the channels.

[0032] The catalytic activity test is the same as in Example 1. The results are shown in Table 1.

Embodiment 3

[0034] Doped α-MnO 2 Preparation of monolithic catalysts. Weigh a certain amount of 5%Ag30%Ti-MnO 2 , add a certain proportion of deionized water and 5-50% silica gel adhesive, stir at a high speed for 1-24 hours, and obtain a certain concentration of doped α-MnO 2 slurry. The doped α-MnO was extracted by vacuum-negative pressure extraction technology 2 The slurry is coated on the pre-treated honeycomb ceramics or porous metal foam, and fired at 500°C for 12h to obtain doped α-MnO 2 monolithic catalyst. Denoted as "integral AgTi-MnO 2 ".

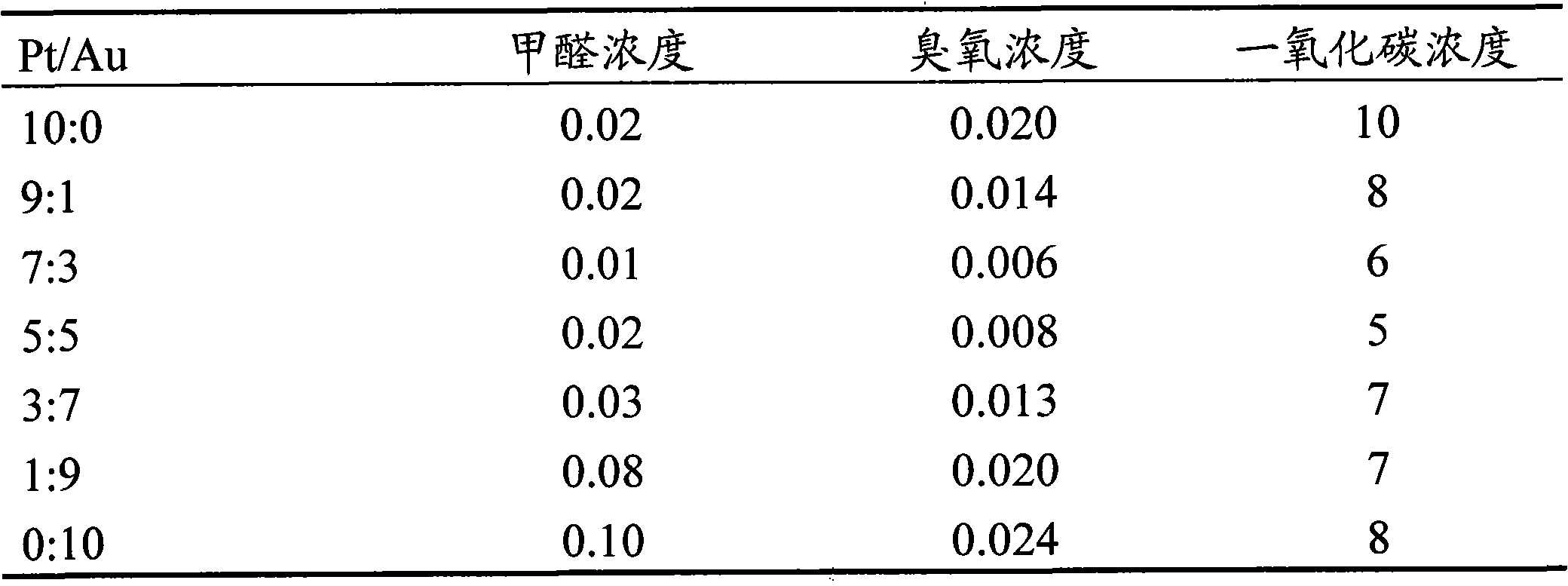

[0035] The performance test of the monolithic catalyst is carried out in the air purifier EN of Huanengtong Group TM Carried on. The three-dimensional of monolithic catalyst is 150*150*40mm3 , and then put it into the air purifier, at room temperature (20°C) and relative humidity of 50%, pass through the air containing 0.1 ~ 50mg / m 3 Formaldehyde, 1~100mg / m 3 Ozone and 10~500mg / m 3 In carbon monoxide air, the wind speed is 2.5m / s....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com