Wafer-level vacuum encapsulating method for micro-electromechanical device

A technology for vacuum packaging and device wafers, which is used in microstructure devices, processing microstructure devices, metal processing mechanical parts, etc., and can solve problems such as changing the performance of anti-reflection coatings or getters, so as to reduce failure rates and avoid failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

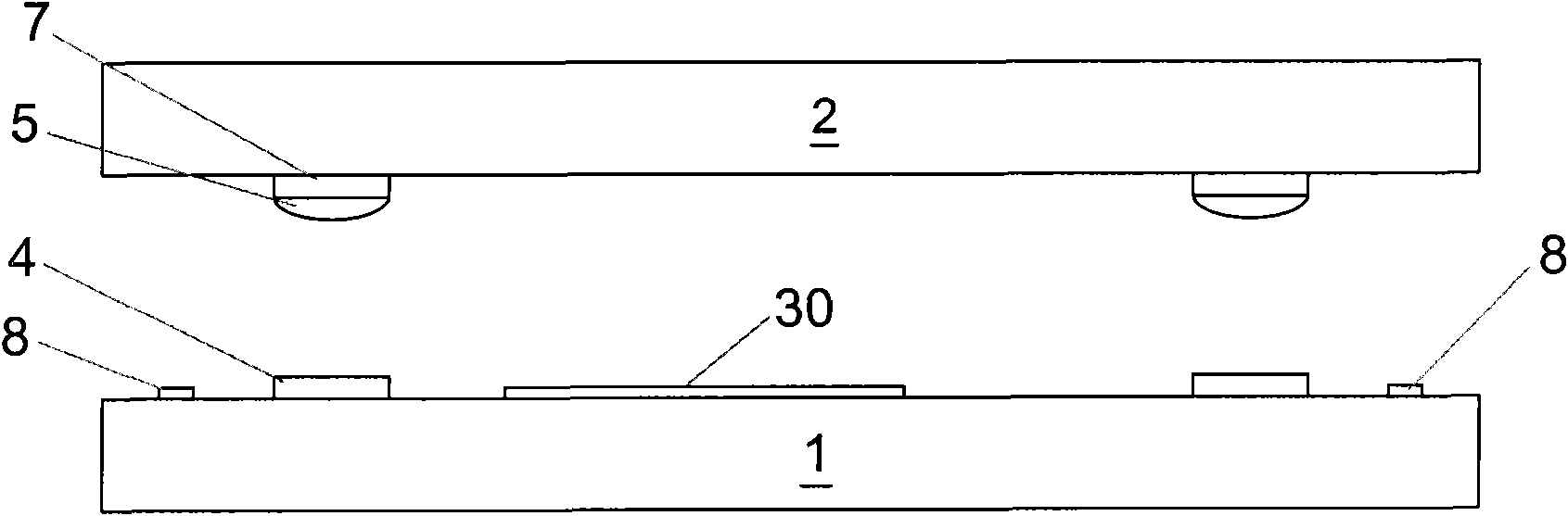

[0051] The wafer-level vacuum packaging method for micro-electromechanical devices will be described below by taking the packaging of an uncooled infrared microbolometer chip as an example.

[0052] refer to Figure 3A-Figure 3H , Figure 4 and Figure 5 . According to the method of the present invention, the wafer-level vacuum packaging method of the uncooled infrared microbolometer chip 30 includes the following steps in sequence:

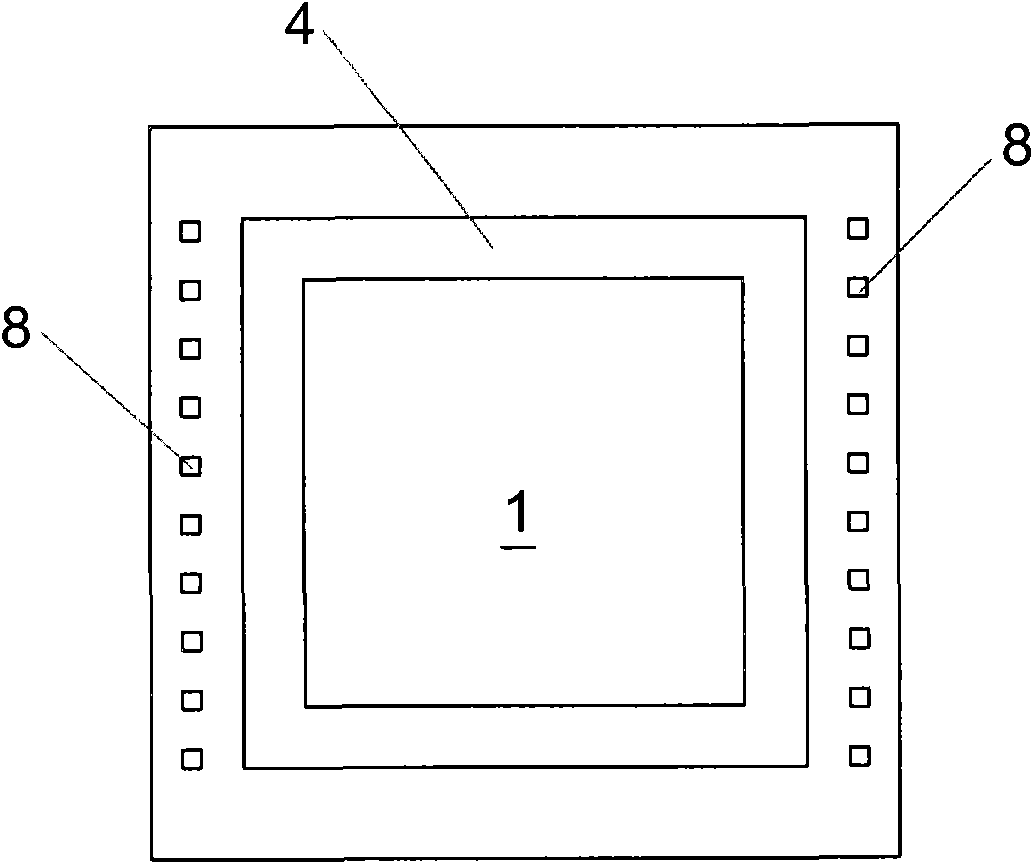

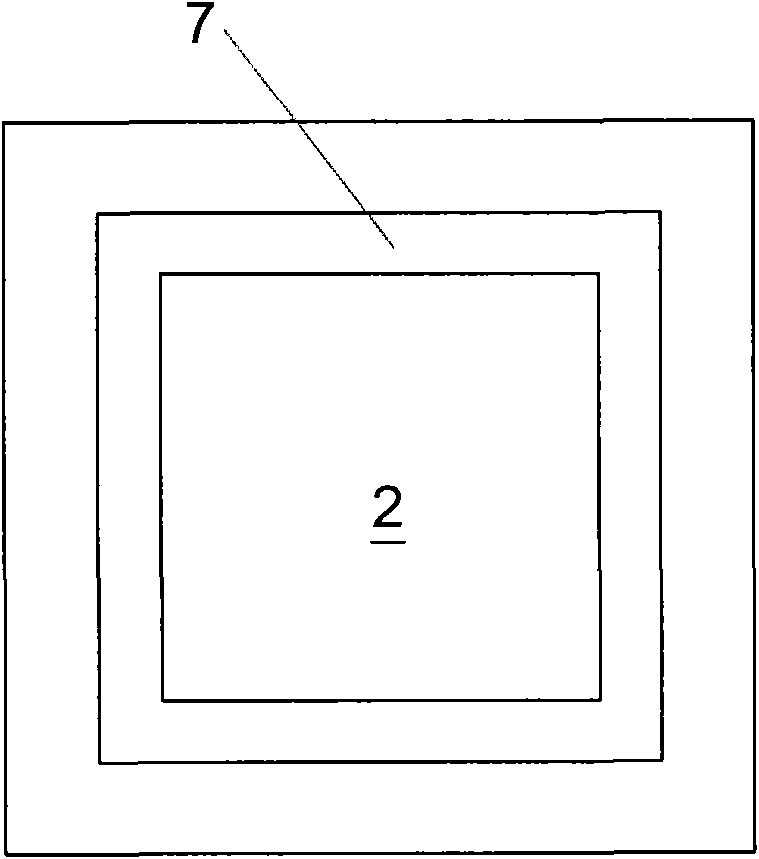

[0053] S1. Wafer preparation: Prepare capping wafer 2 and device wafer 1, wherein capping wafer 2 is silicon single crystal or germanium single crystal grown by fusion method, with crystal orientation ; device wafer 1 has been prepared There are uncooled infrared microbolometer 30 and lead plate 8.

[0054] S2. Growing sealing rings 4 and 7 on the front of the device wafer 1 and the front of the capping wafer 2 respectively, the specific steps are:

[0055] S2a. Spin-coat a photoresist (positive resist) of about 2um on the front of the devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com