Method for synthesizing ZnO nanometer stick array on large scale

A nanorod array and large-scale technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as complex processes, and achieve the effects of simple equipment conditions, mild reaction conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

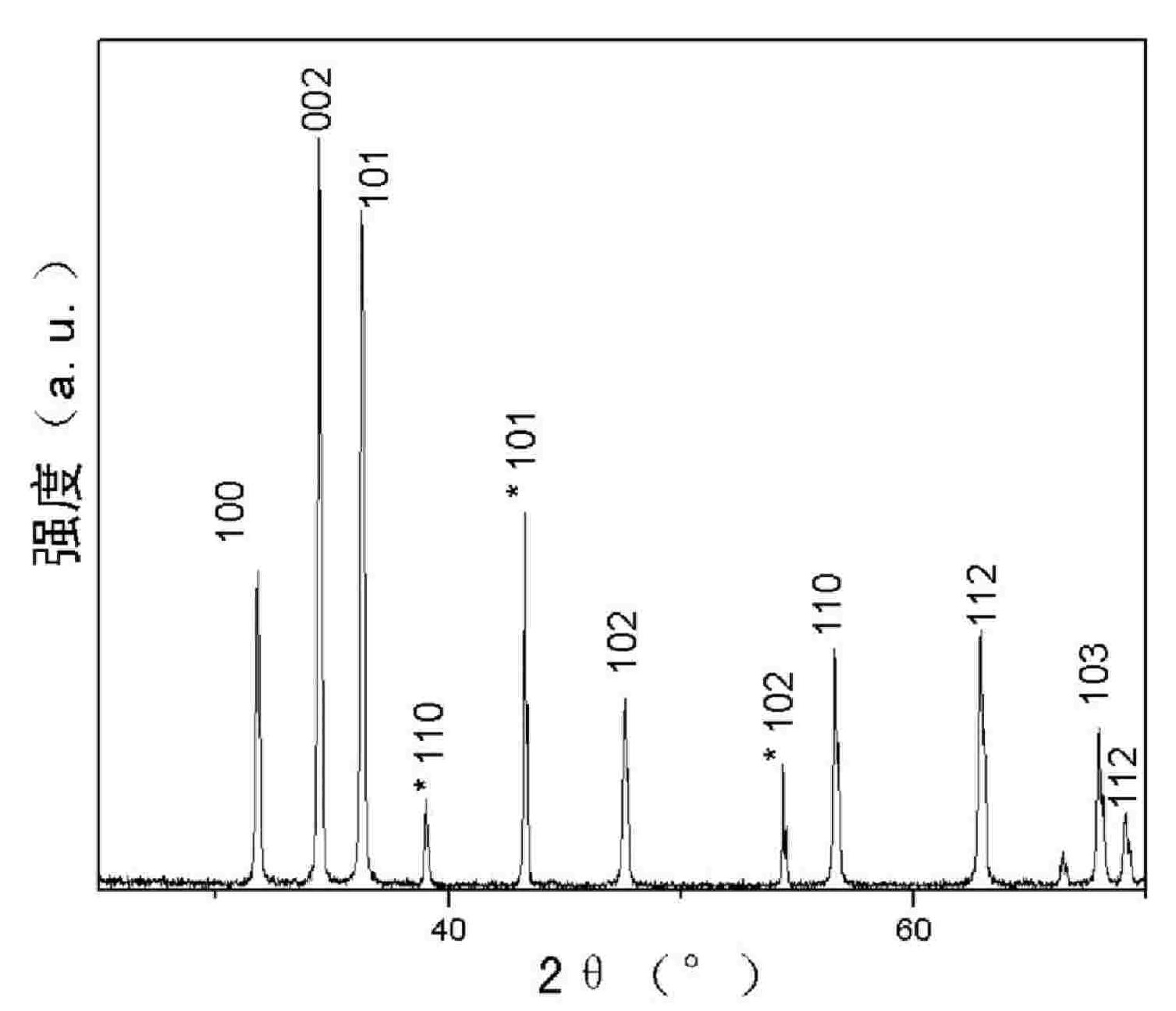

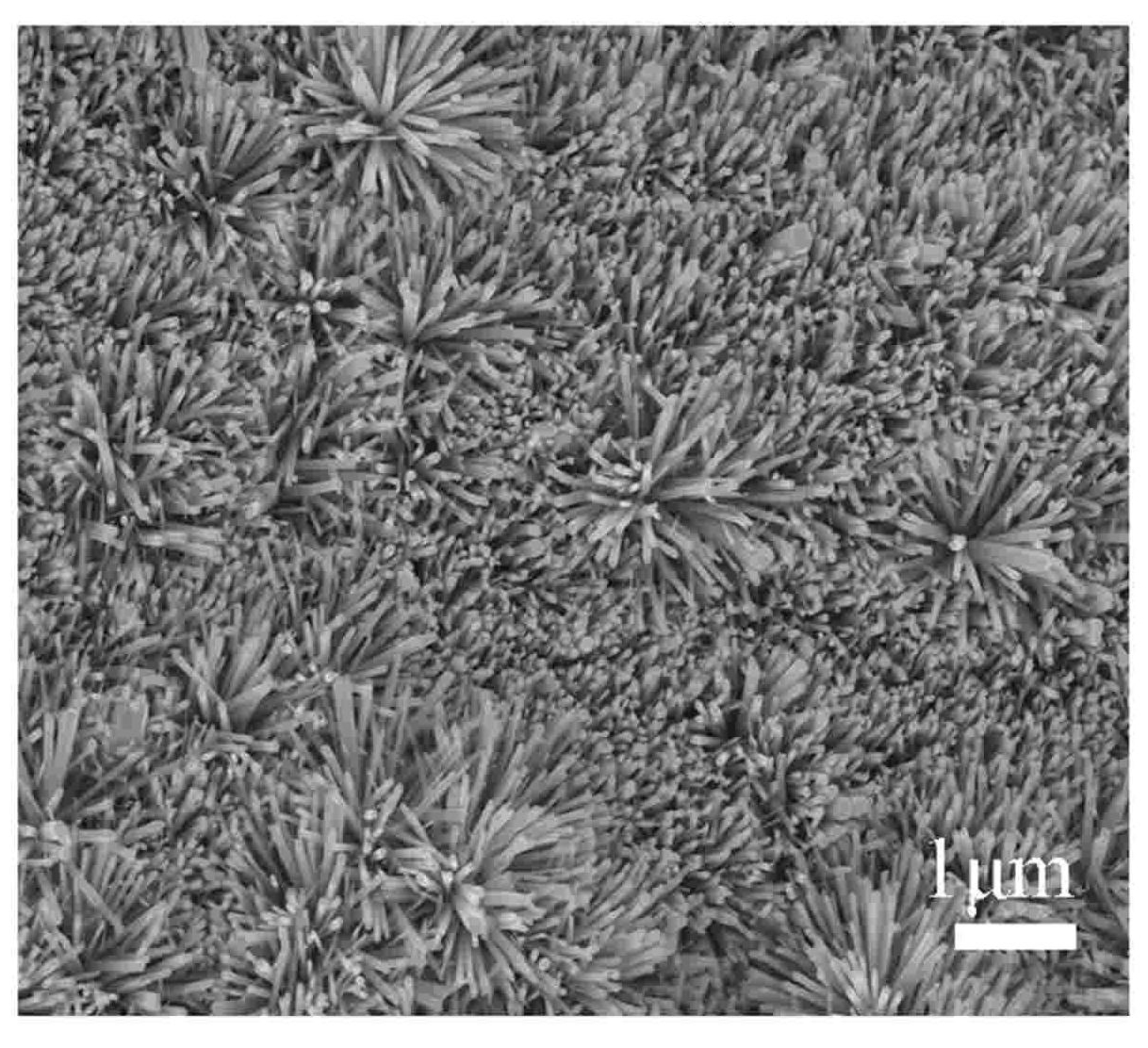

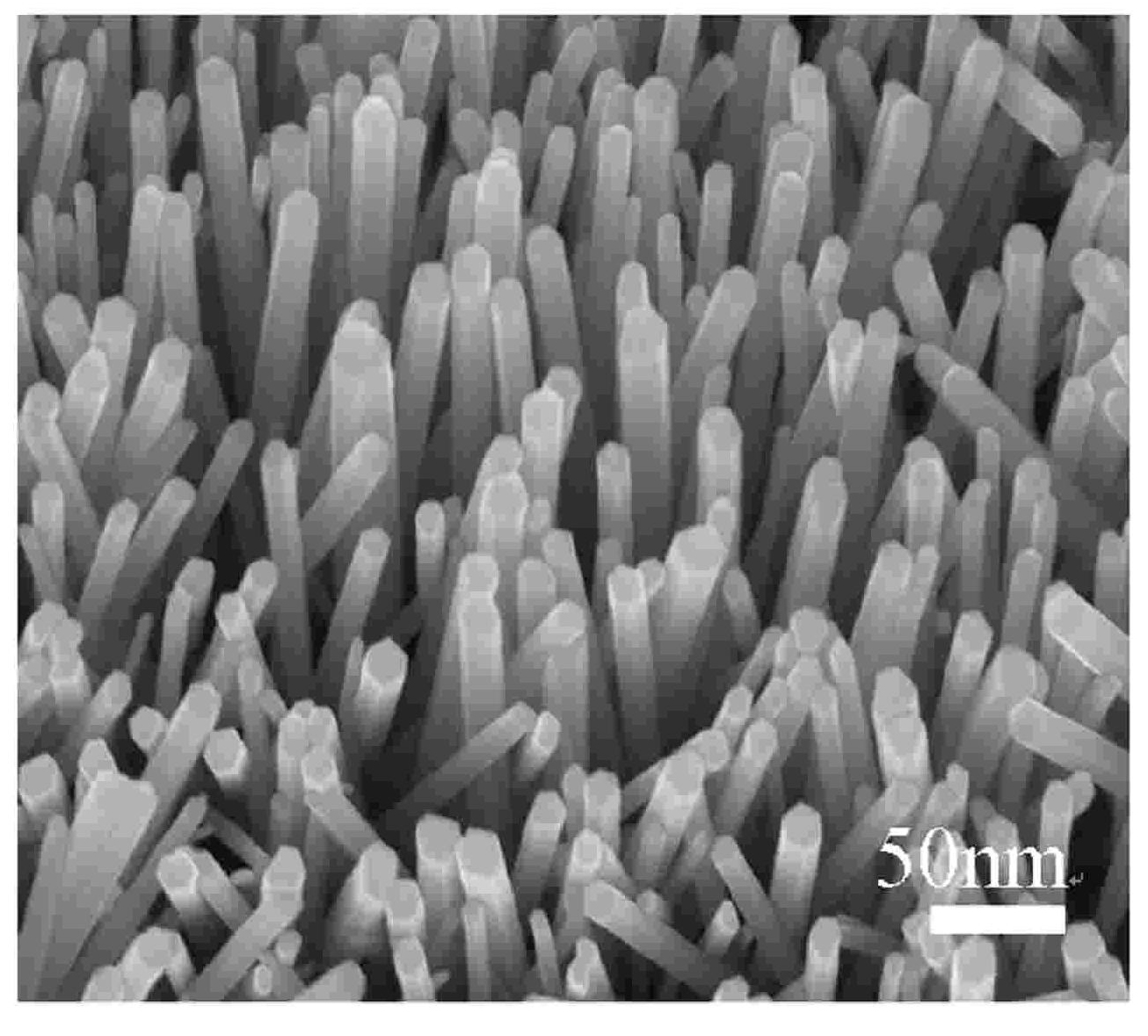

[0009] Specific Embodiment 1: The method for large-scale synthesis of ZnO nanorod arrays in this embodiment is achieved through the following steps: 1. After mixing zinc acetate and hexamethylenetetraammonium, add it to deionized water, stir and dissolve for 20 to 40 minutes, and then Then add ammonia, stir to obtain a mixed solution, wherein the mol ratio of zinc acetate and hexamethylenetetraammonium is 1: 1, the mol ratio of ammonia and zinc acetate is 0.2: 1, the molar weight of zinc acetate and the volume of deionized water The ratio is 1mol: 6L; 2. Put the zinc flakes in absolute ethanol and ultrasonically clean them for 20-40min; Heating to 120-150° C., keeping it warm for 6-8 hours, then cooling naturally, taking out the zinc sheet, washing with deionized water and drying to obtain the ZnO nanorod array.

[0010] The dosage of the mixed solution in Step 3 of this embodiment only needs to submerge the zinc sheet.

[0011] The method of this embodiment is simple and eas...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, stir and dissolve for 30 minutes to obtain a mixed solution. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, a digitally controlled ultrasonic cleaner of model KQ2200DB is used for ultrasonic cleaning with an ultrasonic power of 50% to 99% of the rated power. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com