Novel method for preparing vinyl acetate from bioethanol

A vinyl acetate and bio-ethanol technology, applied in the new field of bio-ethanol preparation of vinyl acetate, can solve problems such as declining economic competitiveness and soaring oil prices, improve market competitiveness, solve carbon deposition, reduce process water consumption and process The effect of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

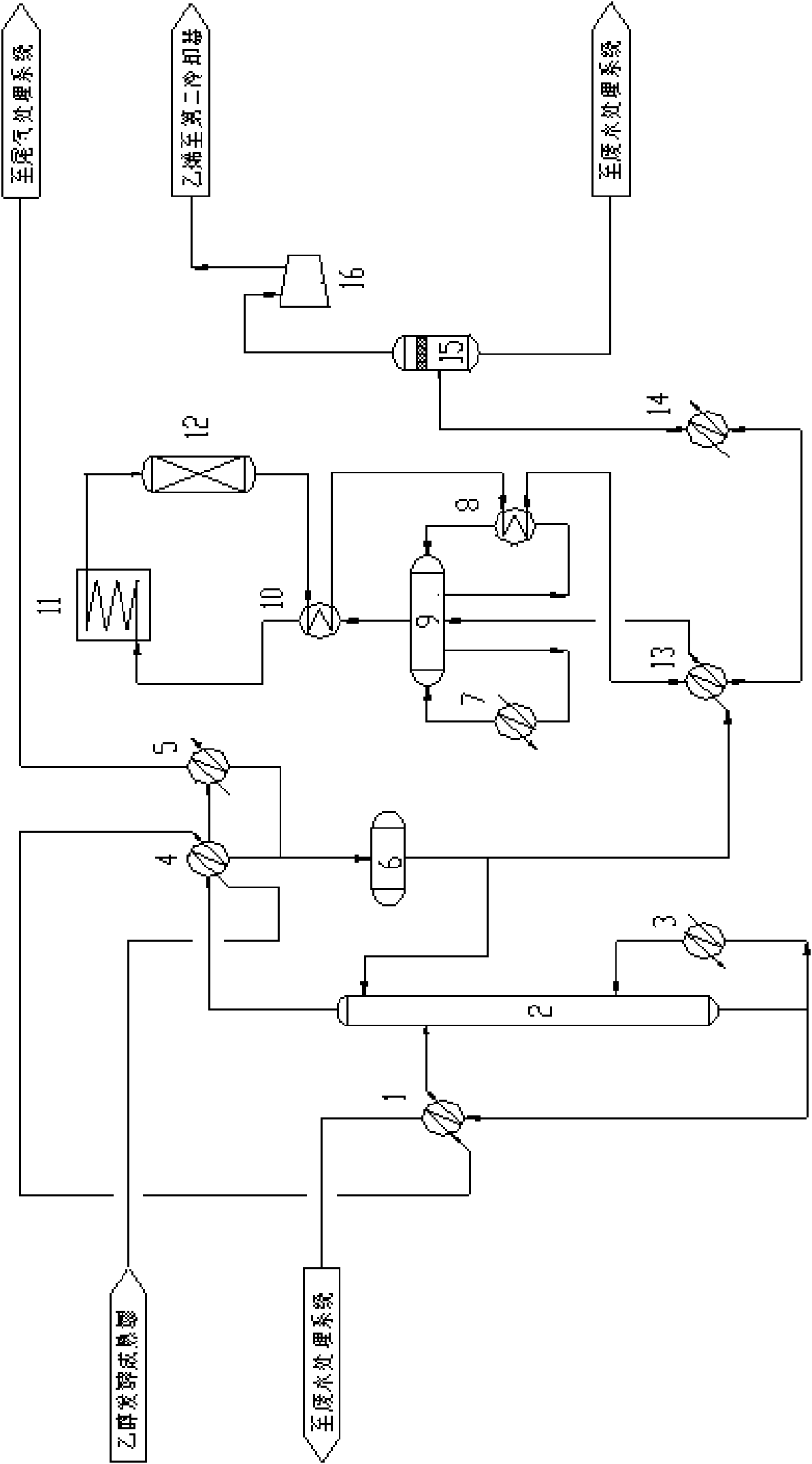

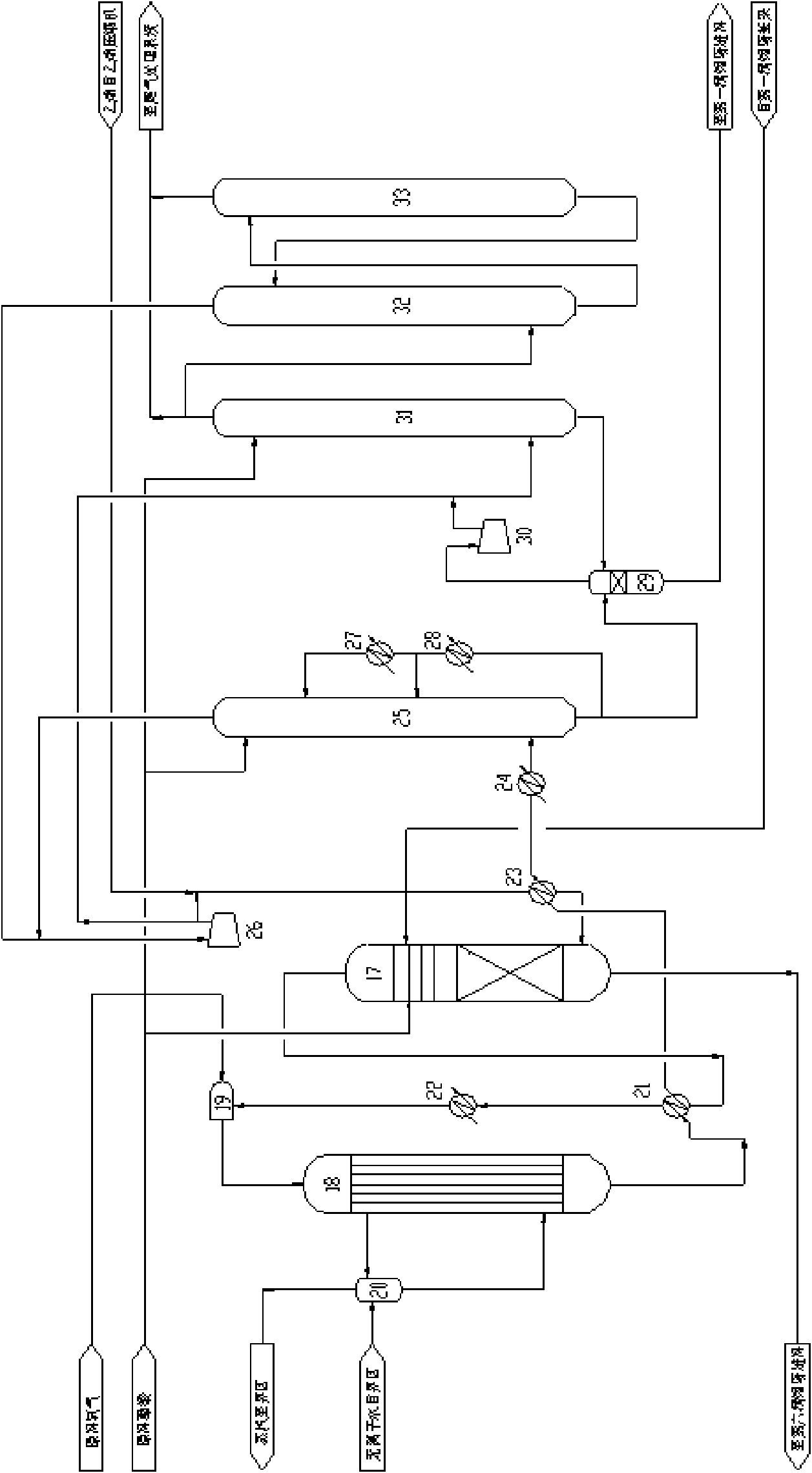

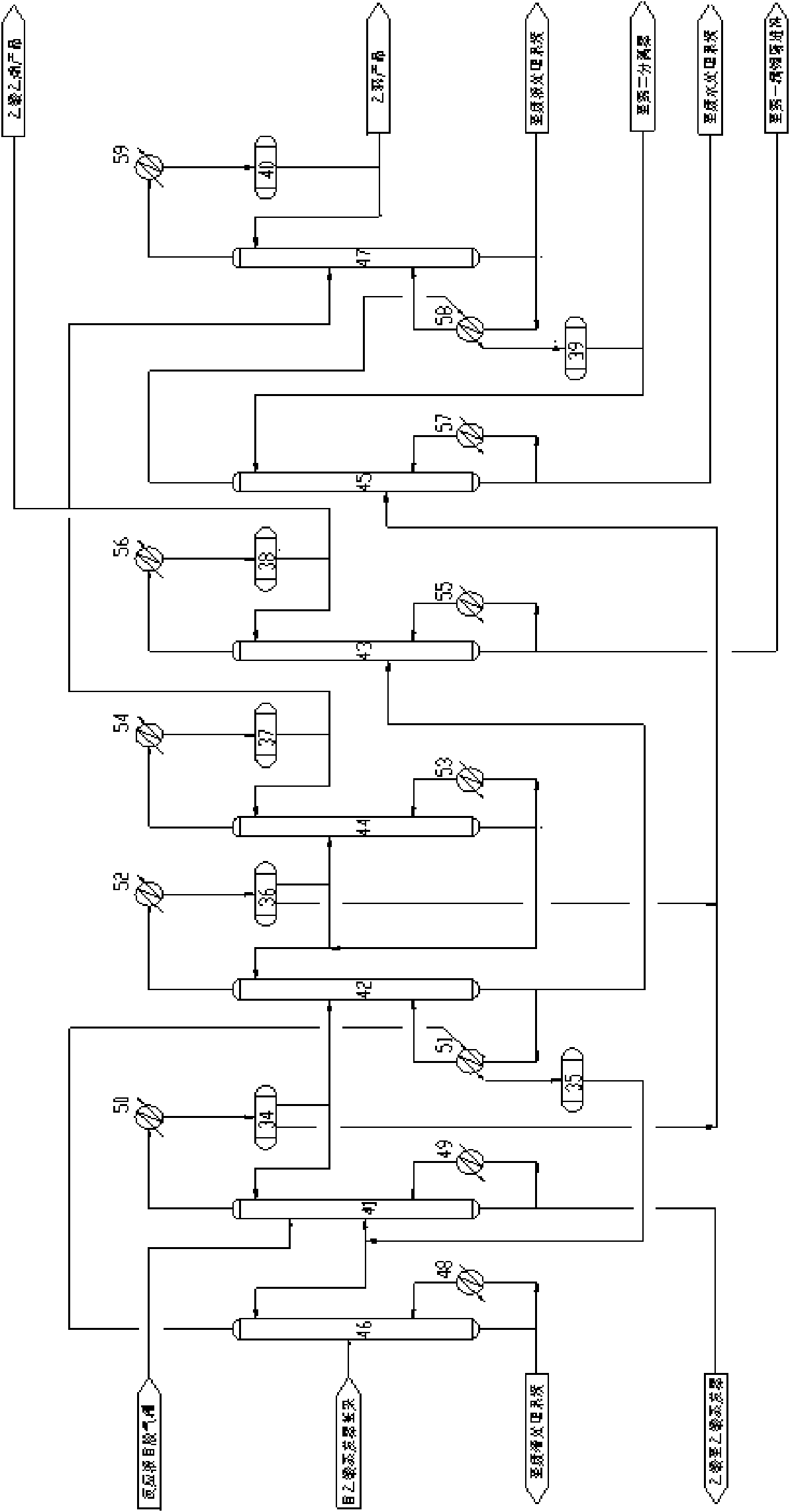

[0040] Using cassava ethanol fermented mature mash as raw material, using figure 1 , figure 2 , image 3 A new method for preparing vinyl acetate from bioethanol shown in the figure is operated to produce vinyl acetate products.

[0041] 1. Bio-ethylene production unit

[0042] The ethanol fermentation mature mash from the alcohol fermentation unit is first preheated as the cooling medium of the overhead condenser 4 of the ethanol distillation tower, and then further heated by the tower bottom liquid cooler 1, and finally enters the ethanol distillation tower 2 as a feed material for refining. Distillation operation, the ethanol volume concentration of the ethanol fermentation mature mash is 12%, the operating pressure (absolute pressure) of the ethanol distillation tower 2 is 0.1MPa, and the ethanol fermentation mature mash removes water, organic acids and heavy component impurities in the ethanol distillation tower. The top steam is passed through the tower top condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com