Production method of high-temperature and high-frequency foam fluorine plastic coaxial cable

A technology of coaxial cable and manufacturing method, which is applied in high-temperature and high-frequency foamed fluoroplastic coaxial cable and its manufacturing field, and can solve the problems of poor wear resistance and mechanical strength, cable enlargement or uniformity deterioration, cable core conductor oxidation, etc. problems, to achieve the effect of improving wear resistance and mechanical strength, preventing deterioration due to moisture, and high electrical transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

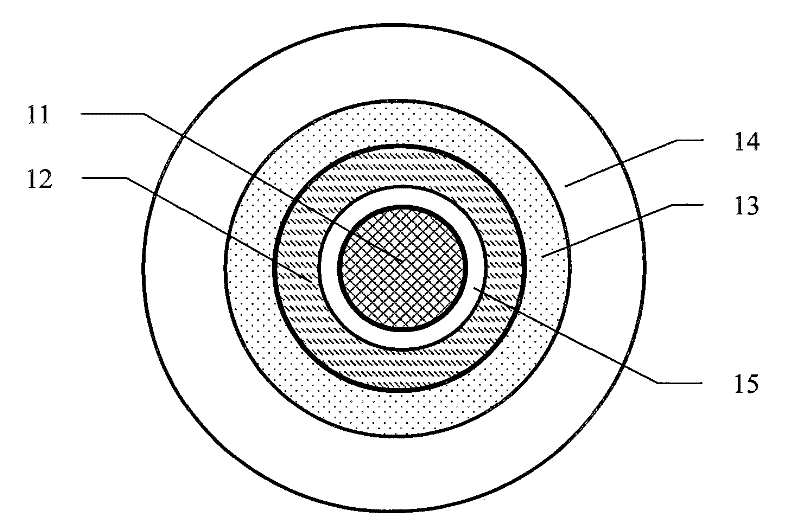

[0035] Such as figure 1 As shown, a high-temperature and high-frequency foamed fluoroplastic coaxial cable provided by the first embodiment of the present invention, the coaxial cable consists of a core conductor 11, a PTFE wrapping layer 12, a metal shielding layer 13 and The sheath 14 is characterized in that a layer of PFA layer 15 is provided between the cable core conductor 11 and the PTFE wrapping layer 12 .

[0036] The method for manufacturing high-temperature and high-frequency foamed fluoroplastic coaxial cables provided by the first embodiment of the present invention is characterized in that the specific steps are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com