Collecting electrode used for traveling wave tube and manufacture method thereof

A manufacturing method and collecting electrode technology, applied in the direction of traveling wave tube, non-luminescent electrode manufacturing, time-of-flight electron tube collector, etc., can solve the problems of easy falling off, poor thermal conductivity of coating film, hindering heat export, etc., and reach the melting point High, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

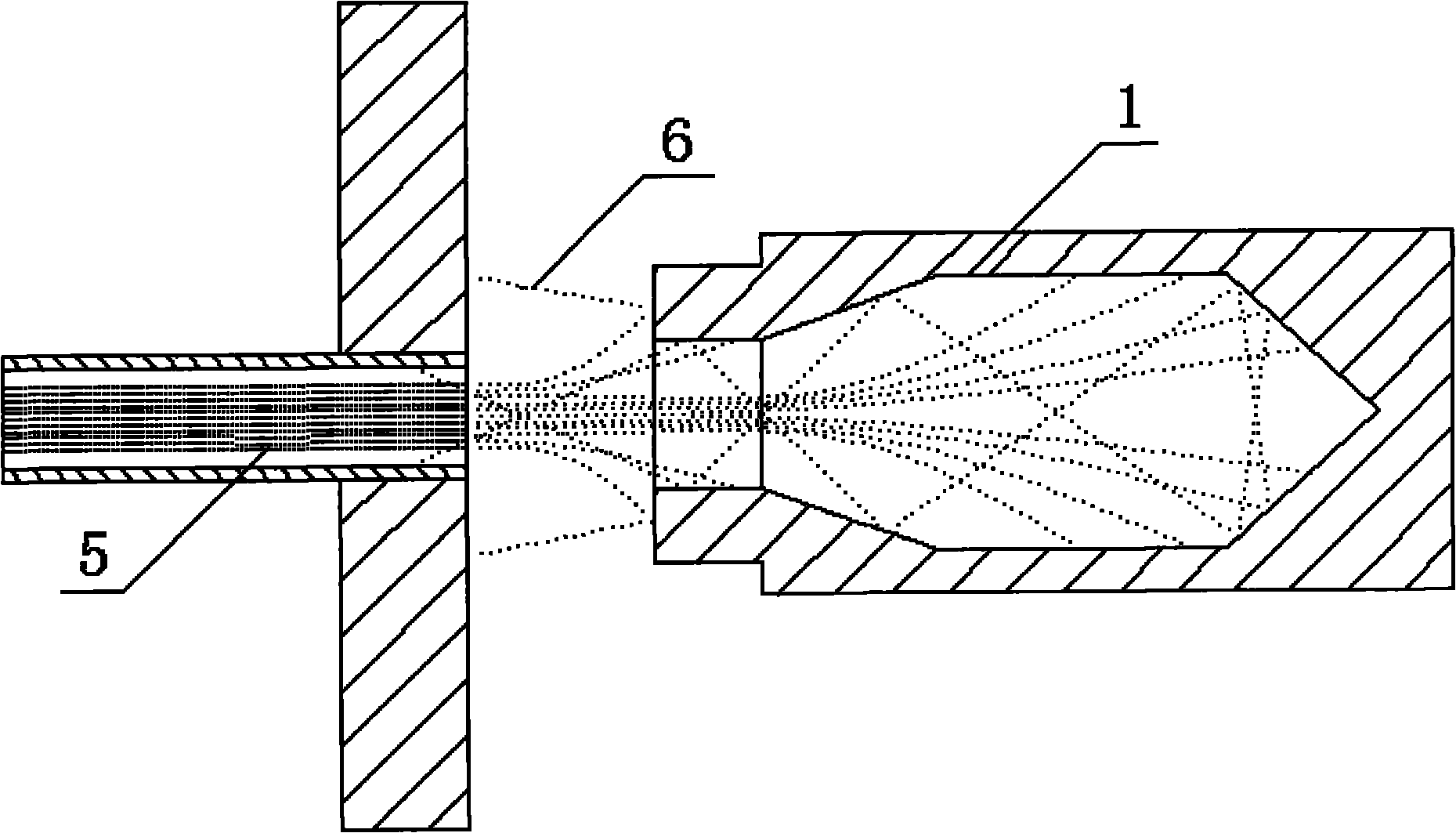

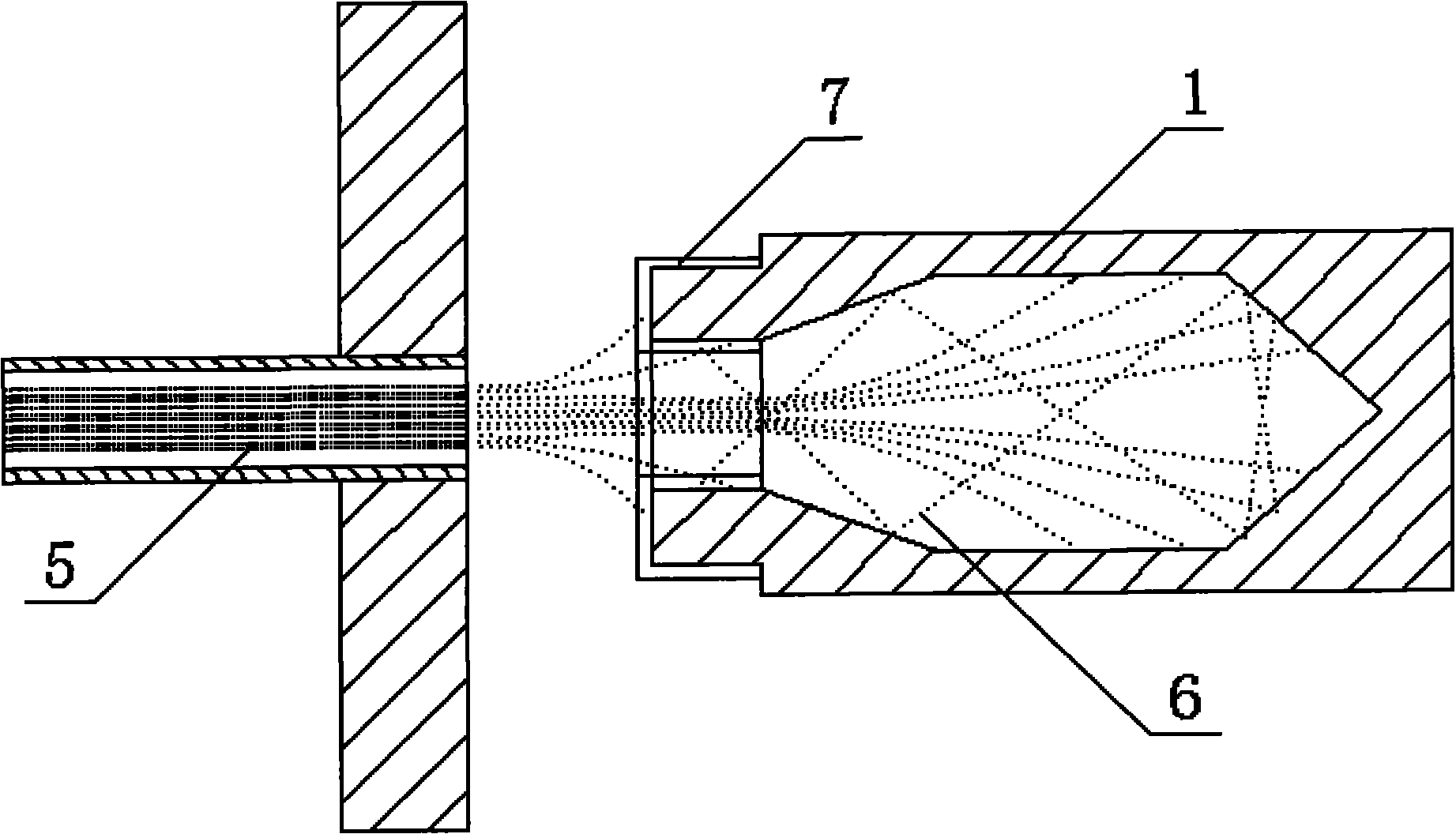

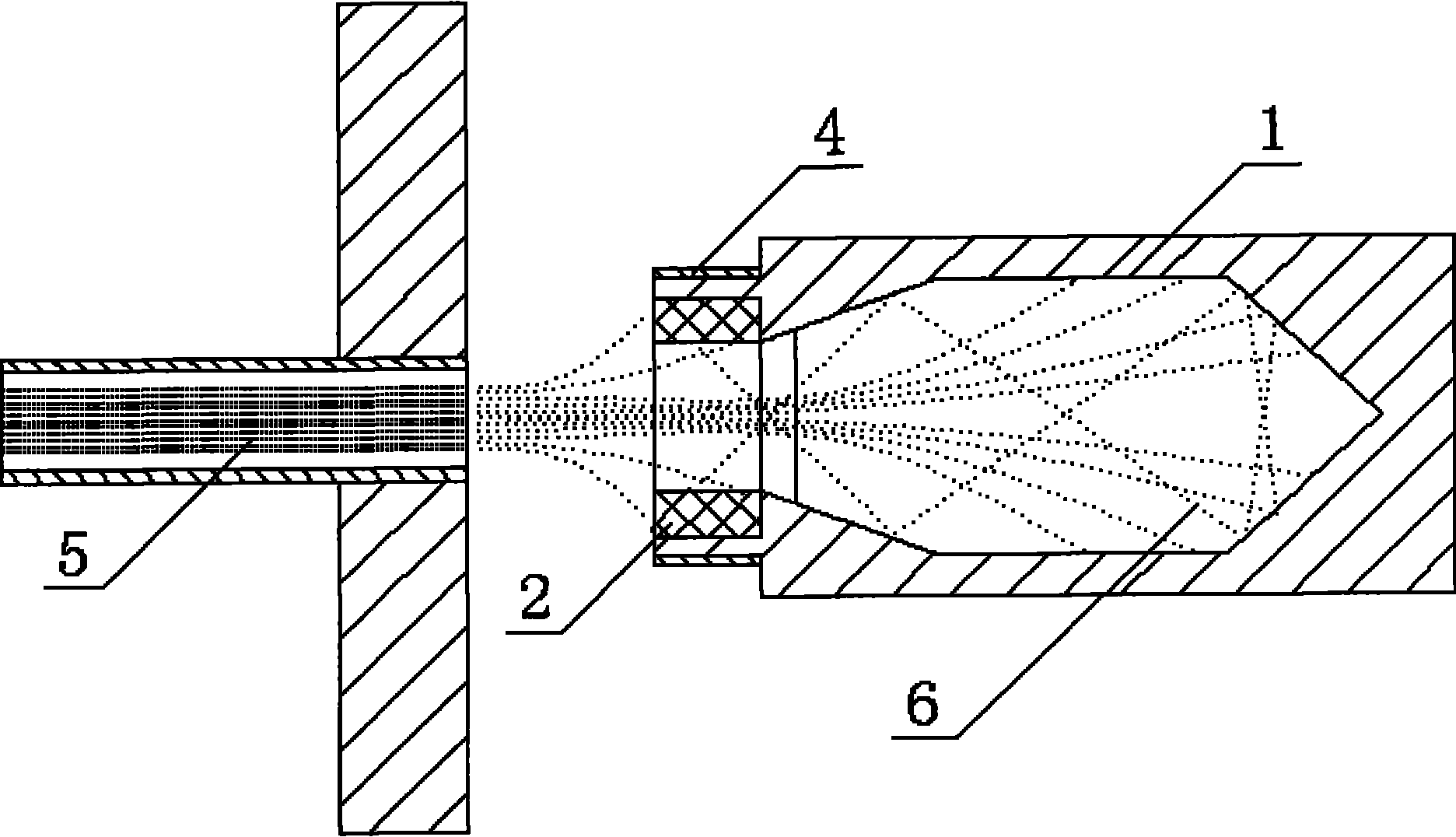

[0031] figure 1 Shown is the schematic diagram of the electron trajectory at the collector without coating in the prior art. The collector is bombarded by the high-speed electron beam 5 in the process of collecting electrons. The electrons bombarded on the collector have the following three types: a class of electrons from the collector The pole port directly enters the collector, and the reflection on the inner wall of the collector disappears in the collector, and is exported by the collector in the form of heat; the second type of electrons enters the collector from the collector port, and overflows the collector through the reflection on the inner wall of the collector And flow back into the slow wave to form return electrons 6; the three types of electrons directly bombard the collector port, and flow back to the slow wave to form return electrons 6 after being reflected by the collector port. Among them, the second and third types of electrons have great harm to the trav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com