Process for texturing crystalline silicon solar cell by dry etching

A solar cell and dry etching technology, which is applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problem of difficulty in controlling the size and shape of the suede on the silicon surface, large reflection loss on the surface of solar cells, and low external quantum efficiency and other issues to achieve the effect of improving external quantum efficiency, high cell photoelectric conversion efficiency, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the technical solution of the present invention will be described in detail below with specific examples, but the invention is not limited thereto.

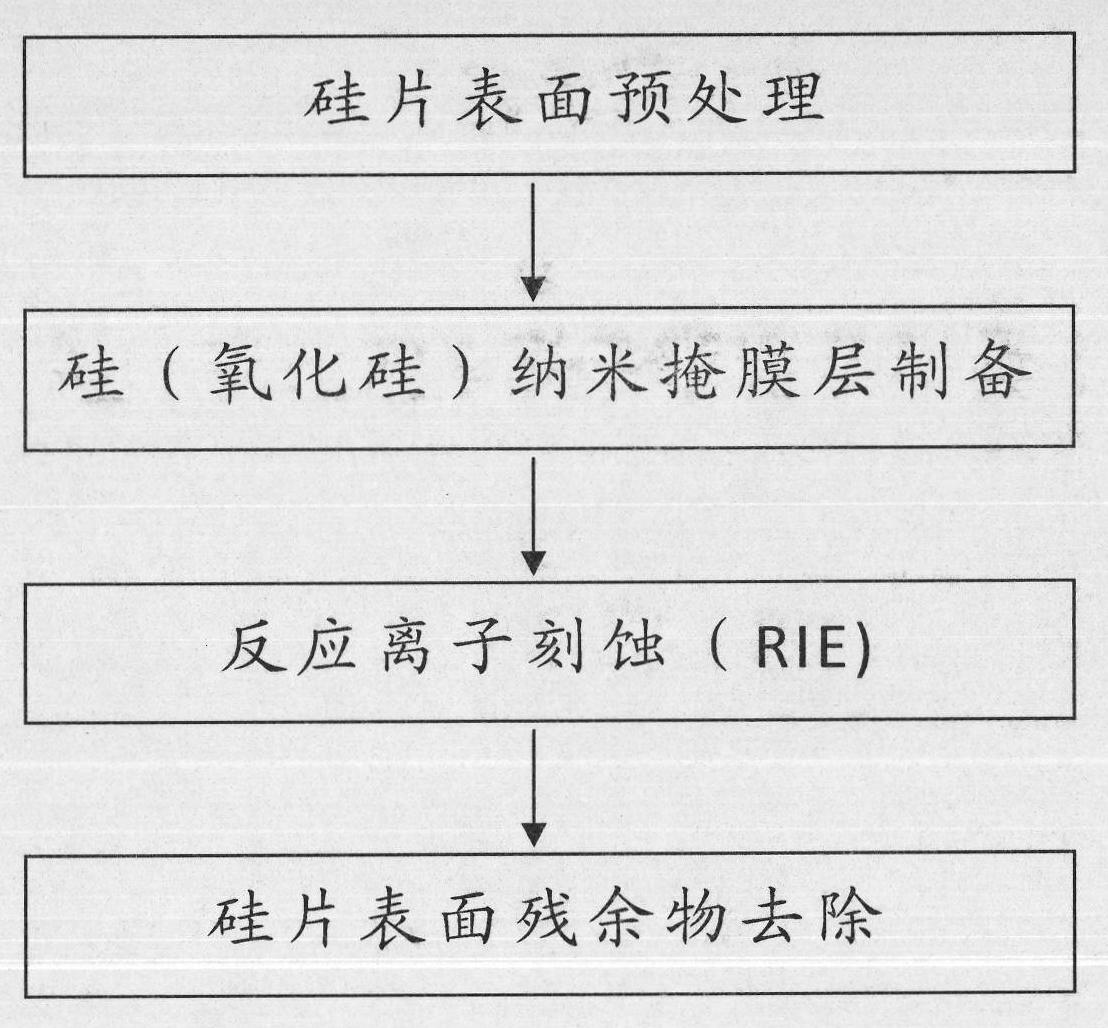

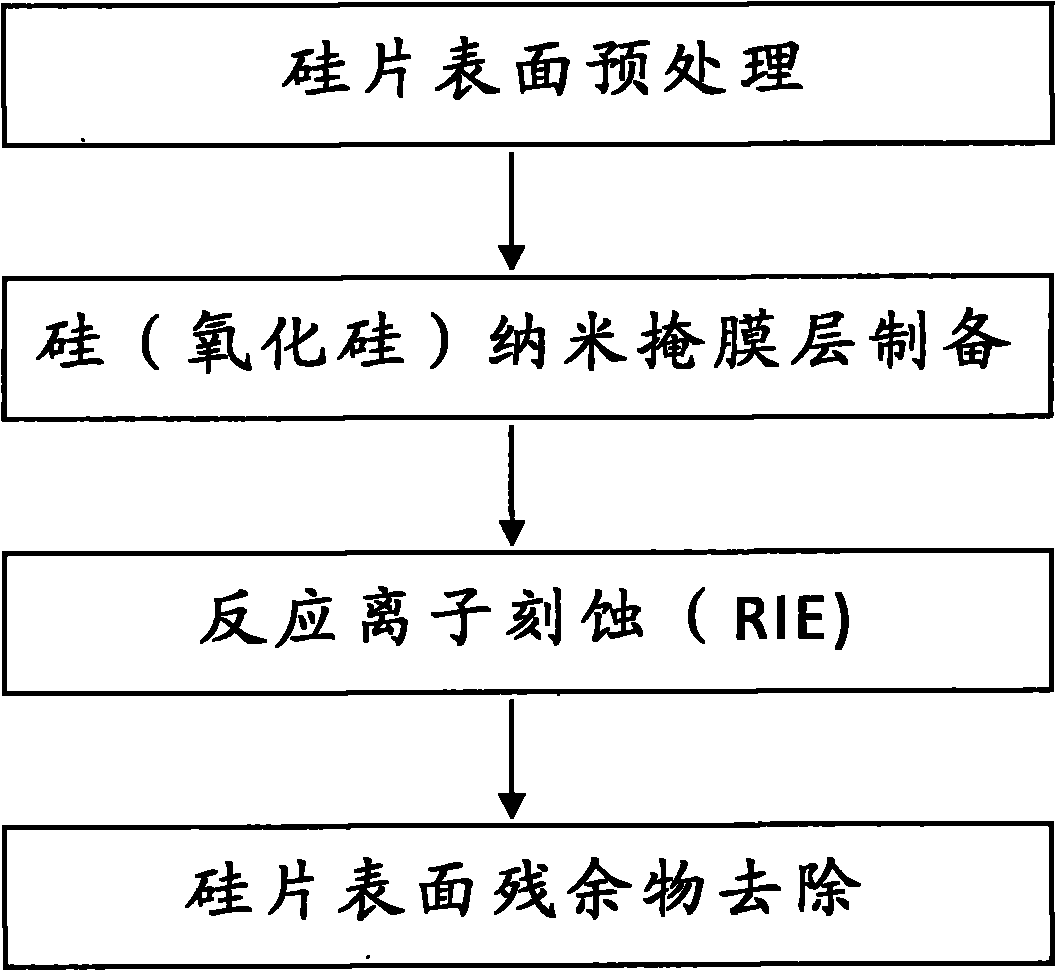

[0023] A dry etching texturing process for crystalline silicon solar cells of the present invention, the technical proposal is: a dry etching texturing process for crystalline silicon solar cells, comprising a silicon chip surface pretreatment step, reactive ion etching (RIE) Step, the silicon wafer surface residue removal step after etching, after the silicon wafer surface is pretreated, a nano-mask layer is prepared on the silicon wafer surface, and then the silicon wafer with the nano-mask layer is carried out by reactive ion etching ( RIE), after removing surface residues at last, a suede surface is formed on the surface of the silicon wafer.

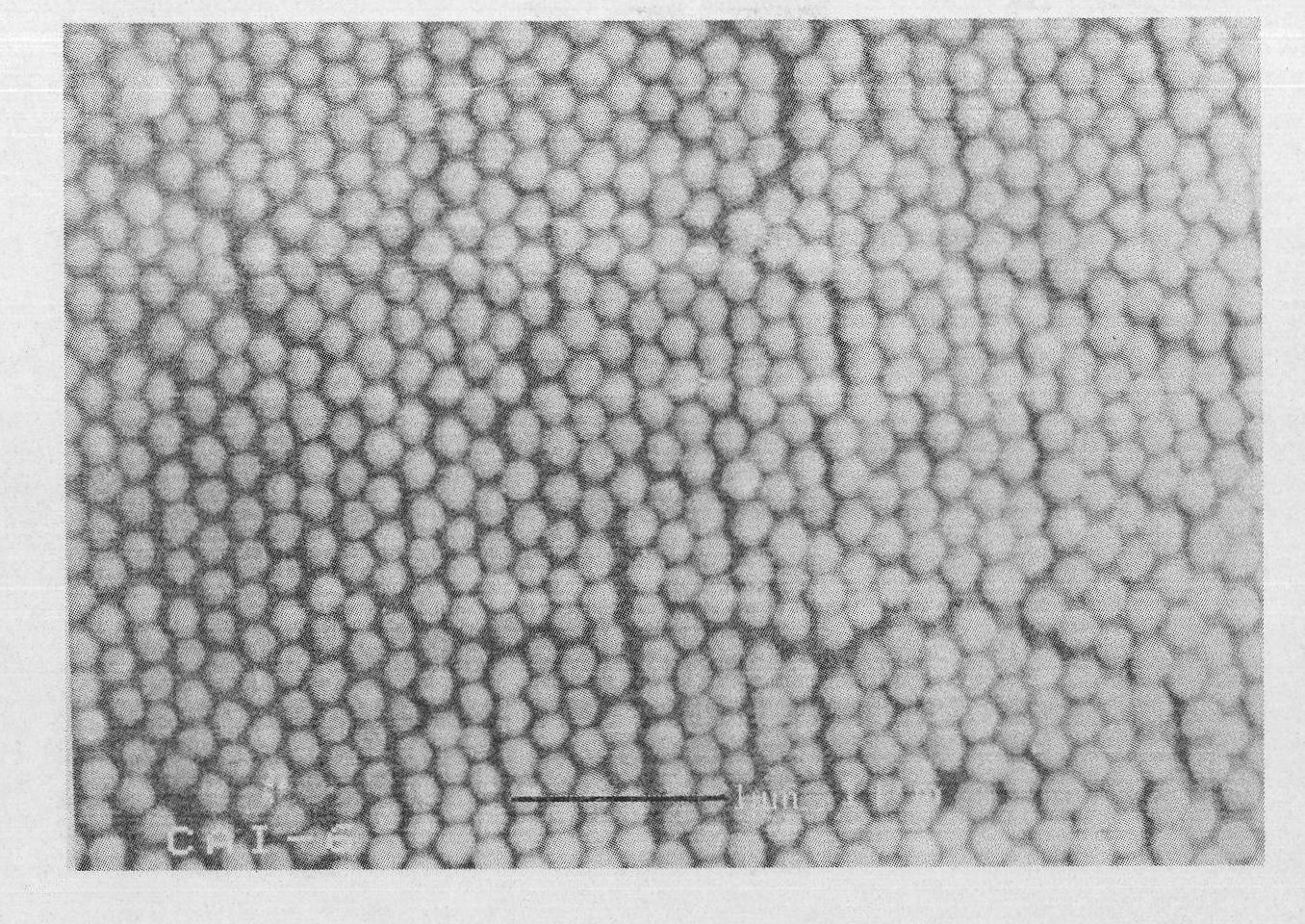

[0024] The nano-mask layer is a monodisperse layer of silicon or silicon dioxide nanospheres.

[0025] The specific steps a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com