Method for preparing biological pesticide spinosad microcapsule preparation

A spinosyn and biological pesticide technology, applied in the field of preparation of biological pesticide spinosyn microcapsule formulations, can solve problems such as unfavorable ecological environment, reduced drug efficacy, increased application amount, etc., and achieves simple process, low equipment investment, controllable The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

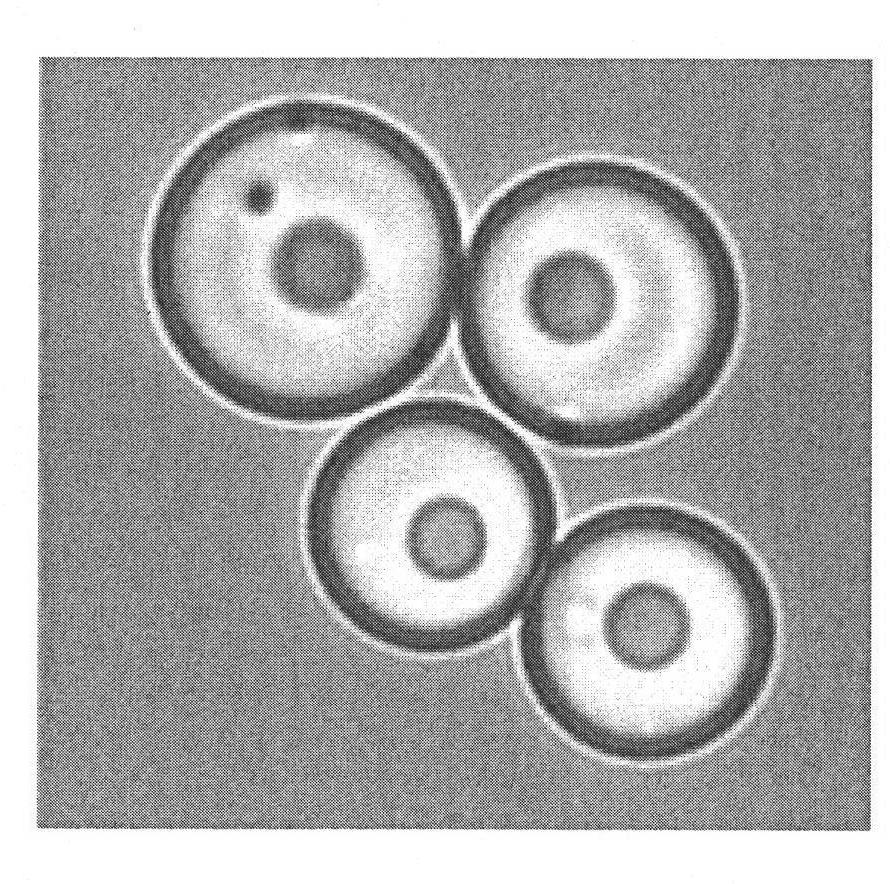

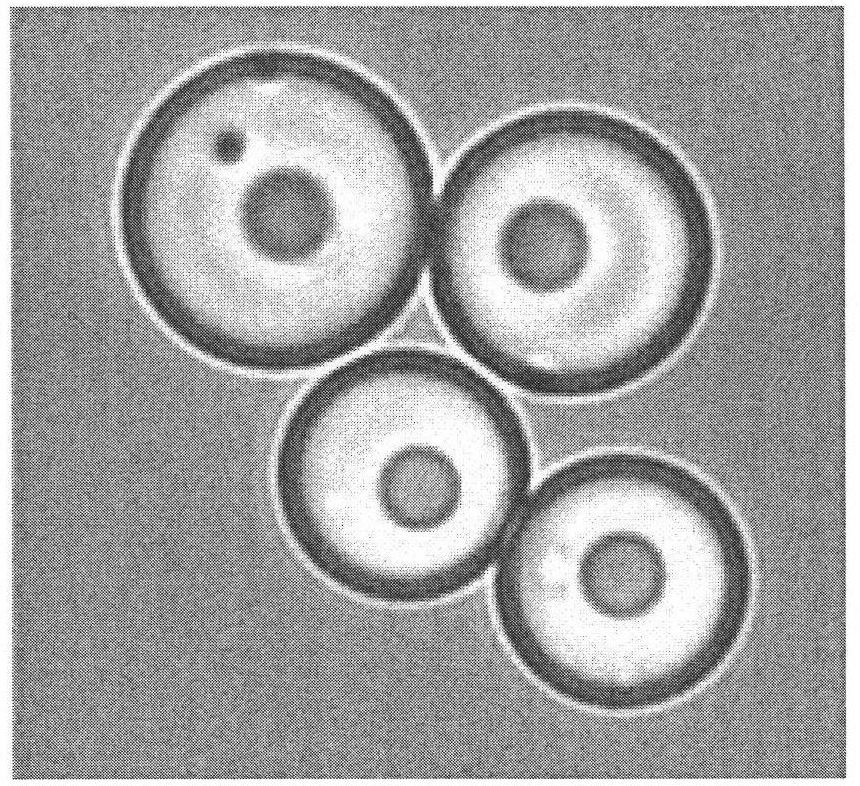

Image

Examples

Embodiment 1

[0023] Accurately weigh 24.0g of urea and add it to a three-necked flask, measure 40mL of 37% formaldehyde solution, stir at a speed of 1000r / min, stir until the urea is completely dissolved, add triethanolamine to adjust the pH to 8.0, gradually raise the temperature to 70°C, and keep stirring The speed and temperature are constant, and the reaction is stopped after 1 hour to form a viscous transparent liquid. Then, add distilled water about 2 times the volume of the formaldehyde solution to dilute to obtain a stable aqueous solution of urea-formaldehyde resin prepolymer.

[0024] Dissolve 1.0 g of spinosad in 10 mL of chloroform completely at room temperature, then add 15 mL of petroleum ether, stir and mix well, then add 70 mL of 0.7% by mass sodium lauryl sulfate aqueous solution as an emulsifier, Stir at 1000r / min for 10min to fully disperse and emulsify the capsule core. Then, add 75mL of the above-mentioned urea-formaldehyde resin prepolymer solution, 1000-2000r / min, co...

Embodiment 2

[0027] Accurately weigh 40.0g of urea and add it to a three-necked flask, measure 100mL of 37% formaldehyde solution, stir at a speed of 1000r / min, stir until the urea is completely dissolved, add triethanolamine to adjust the pH to 8.0, gradually raise the temperature to 70°C, and keep stirring The speed and temperature are constant, and the reaction is stopped after 1 hour to form a viscous transparent liquid. Then, add distilled water about 2 times the volume of the formaldehyde solution to dilute to obtain a stable aqueous solution of urea-formaldehyde resin prepolymer.

[0028] Dissolve 1.5g of spinosad in 25mL of chloroform completely at room temperature, then add 35mL of petroleum ether, stir and mix thoroughly, then add 120mL of styrene-maleic anhydride copolymer with a mass percentage of 0.7% as an emulsifier , Stir at 1000r / min for 10min to fully disperse and emulsify the capsule core. Then, add 240mL of the above-mentioned urea-formaldehyde resin prepolymer solution...

Embodiment 3

[0031] Accurately weigh 36.0g of urea and add it to a three-necked flask, measure 60mL of 37% formaldehyde solution, stir at a speed of 1000r / min, stir until the urea is completely dissolved, add NaOH solution to adjust the pH to 8.5, gradually raise the temperature to 80°C, and keep stirring The speed and temperature are constant, and the reaction is stopped after 1 hour to form a viscous transparent liquid. Then, add distilled water about 2 times the volume of the formaldehyde solution to dilute to obtain a stable aqueous solution of urea-formaldehyde resin prepolymer.

[0032]Dissolve 1.0g spinosad in 30mL petroleum ether completely at room temperature, stir and mix thoroughly, add 0.1% by mass sodium dodecylbenzenesulfonate aqueous solution 120mL as emulsifier, stir at 1000r / min for 10min, Fully disperse and emulsify the capsule core. Then, add 150mL of the above-mentioned urea-formaldehyde resin prepolymer solution, 1000-2000r / min, continue to stir for 15min, then reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com