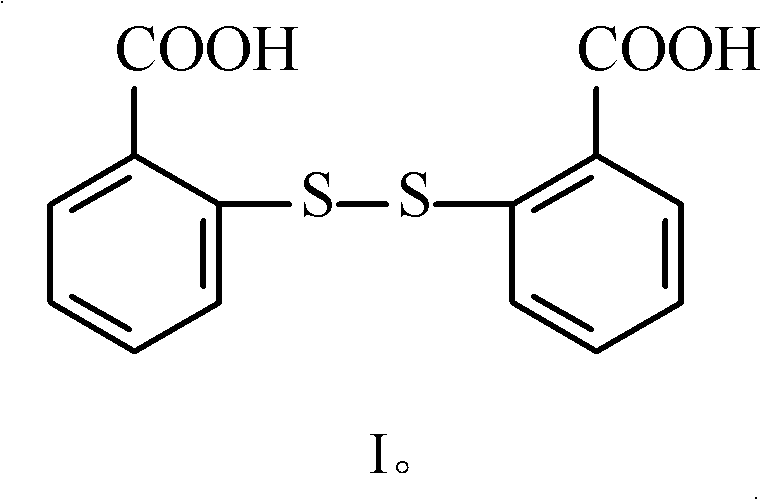

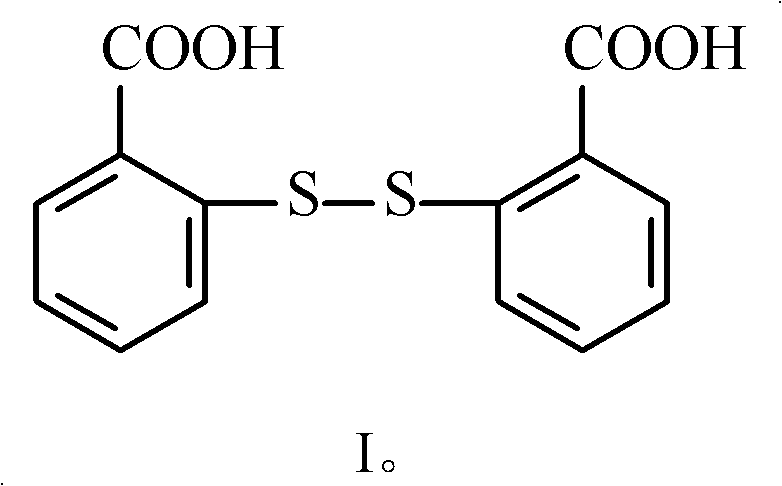

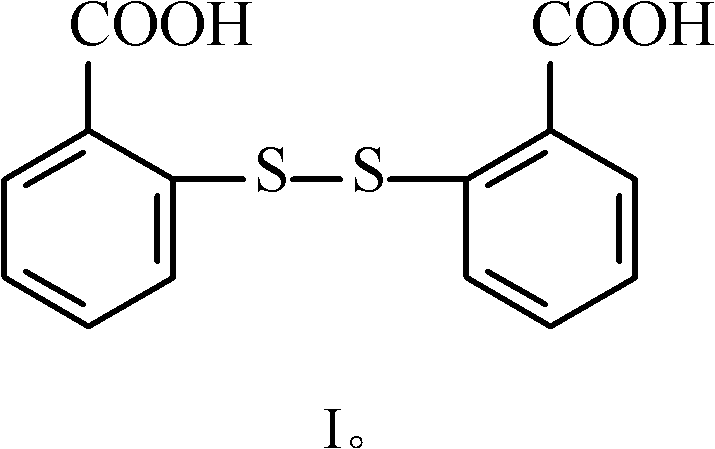

Preparation method of 2,2'-dithio-salicylic acid

A technology of dithiosalicylic acid and liquid sulfur dioxide, applied in 2 fields, can solve the problems of large amount of production waste water, difficult to purify, low product yield and the like, and achieves low production cost, good product purity and high reaction yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 2800 liters of water to 5000 liters of enamel reaction kettle, drop into 400 kilograms of anthranilic acid (dry product, content ≥ 99%, 2.89Kmol), start stirring, add 800 liters of 30% industrial hydrochloric acid (density) in the kettle 1.15kg / L), cool down to 0-5°C with frozen brine, drop a solution consisting of 222kg of sodium nitrite (dry product, content ≥99%, 3.19Kmol) and 600kg of water into the kettle, and react for 2 hours Afterwards, the iodine was tested with potassium chloride starch test paper, the test paper turned blue and the reaction was completed, and about 4500 kg of diazo solution was obtained. (2) Add 300 kg of water, 5 kg of potassium iodide and 6 kg of copper sulfate to the reaction kettle, cool to -10°C, slowly add 370 kg of liquid sulfur dioxide (5.78Kmol) and the above-mentioned diazo solution, and keep warm for 2 hours after adding , be heated up to 100 DEG C and keep warm for 1 hour, then cool down to 40 DEG C, filter and dry to obta...

Embodiment 2

[0023] The preparation process is substantially the same as the method in Example 1, and the difference from Example 1 is that the frozen brine is cooled to 5-10°C, and the feeding amount of sodium nitrite is 242 kg (dry product, content ≥ 99%, 3.47Kmol) , 4 kilograms of sodium iodide and 8 kilograms of cuprous sulfate, the dropping temperature of diazonium solution and liquid sulfur dioxide is -10 ℃, the addition of liquid sulfur dioxide is 555 kilograms, obtains 2,2'-dithiosalicylic acid 441.4 kilograms , The yield in terms of anthranilic acid was 97.9%, and the purity was 98.1% by high performance liquid chromatography.

Embodiment 3

[0025] The preparation process is substantially the same as the method of Example 1, and the difference with Example 1 is that the charging capacity of sodium nitrite is 203 kilograms (dry product, content ≥ 99%, 2.91Kmol), 4.5 kilograms of potassium iodide and 8 kilograms of copper acetate , 278 kilograms of liquid sulfur dioxide to obtain 423.3 kilograms of 2,2'-dithiosalicylic acid, the yield in terms of anthranilic acid was 91.2%, and the purity was 95.3% through high performance liquid chromatography analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com