Glass fiber reinforced polycarbonate material and preparation method thereof

A technology of polycarbonate and glass fiber, which is applied in the field of glass fiber reinforced polycarbonate materials and its preparation, can solve the problems of reducing material toughness, heat resistance, no obvious improvement in rigidity, lower rigidity and heat-resistant temperature, etc. Achieve the effects of good surface appearance, high heat distortion temperature and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

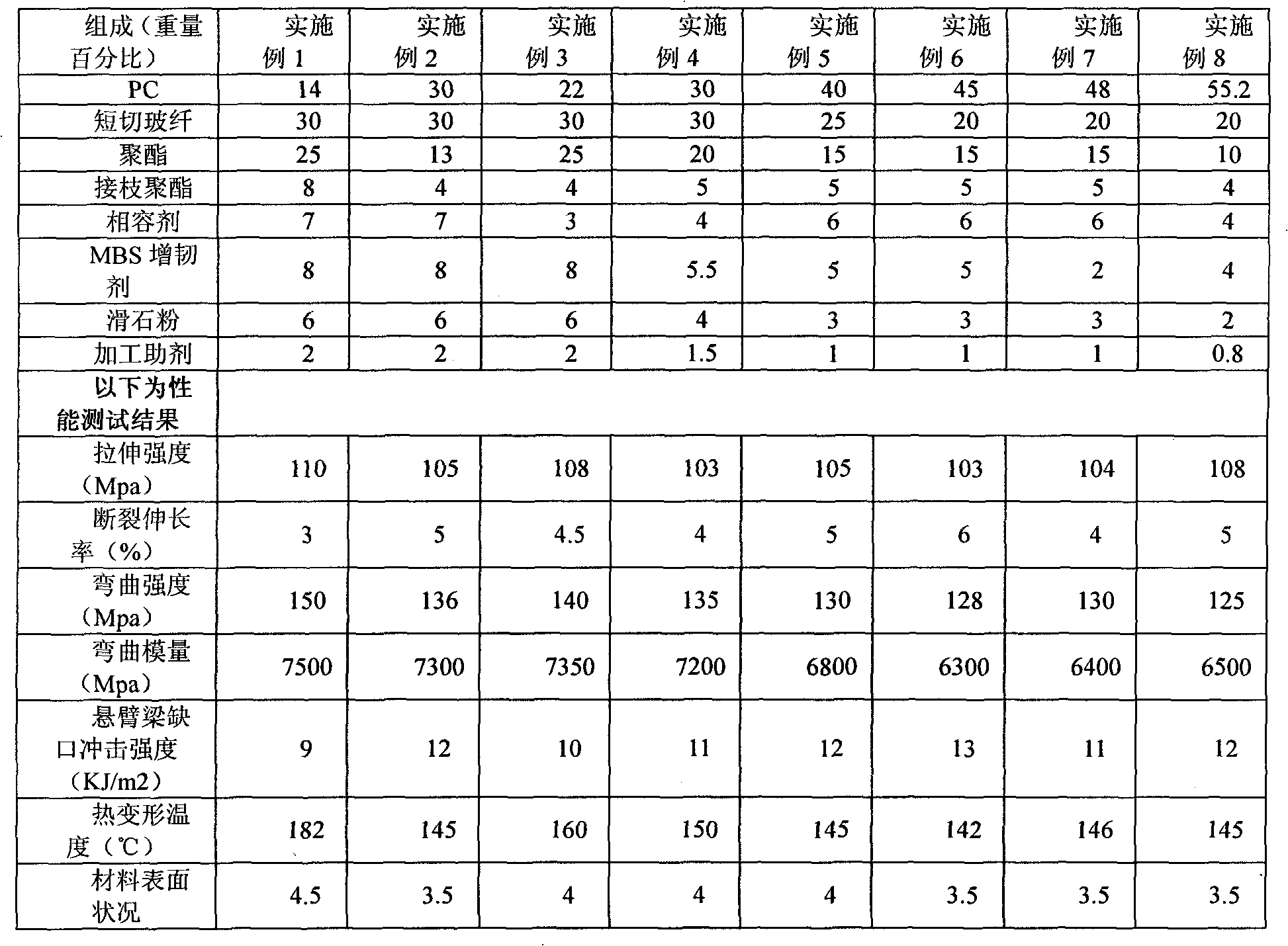

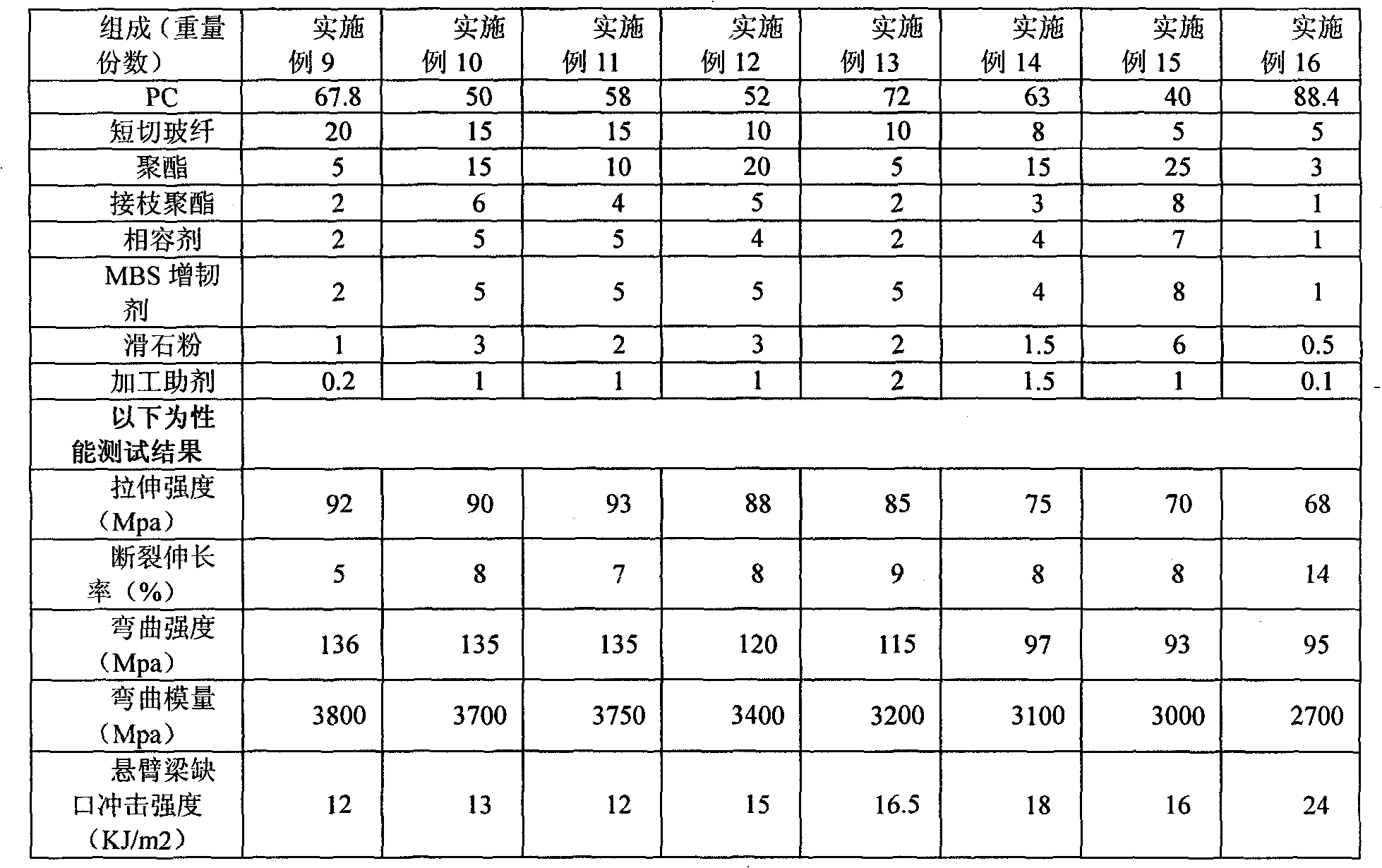

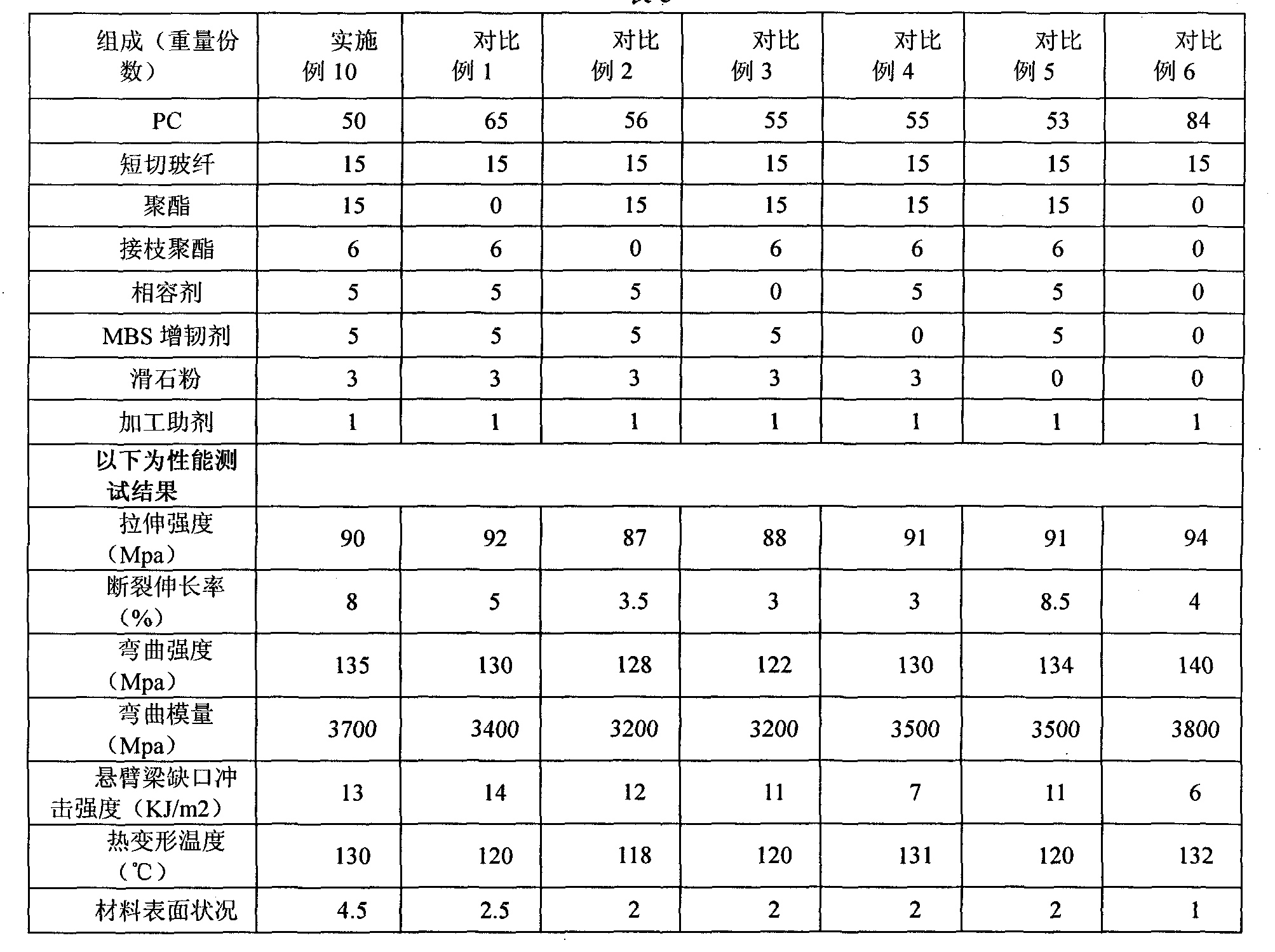

Examples

Embodiment Construction

[0029] In the present invention, TEIJIN's 1225L, BAYER's 2405, and DOW's 201-15 can be used as the polycarbonate.

[0030] In order to further improve the impact strength of the reinforced PC material, a core-shell type MBS elastomer is used as a toughening agent in the present invention, wherein the inner core is methyl methacrylate with a glass transition temperature below 10°C. Ester, as an energy absorber in the process of impact and collision, the outer shell is the two rigid components of styrene and butadiene, which increases the compatibility of the toughener with the external resin matrix. At the same time, in addition to improving the impact toughness of the material, MBS also has good compatibility with the styrene component of the shell and other components, which in turn makes MBS compatible with the glass fiber, other components and additives in the material and the resin matrix. It has a very good improvement effect. In the present invention, the addition ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com