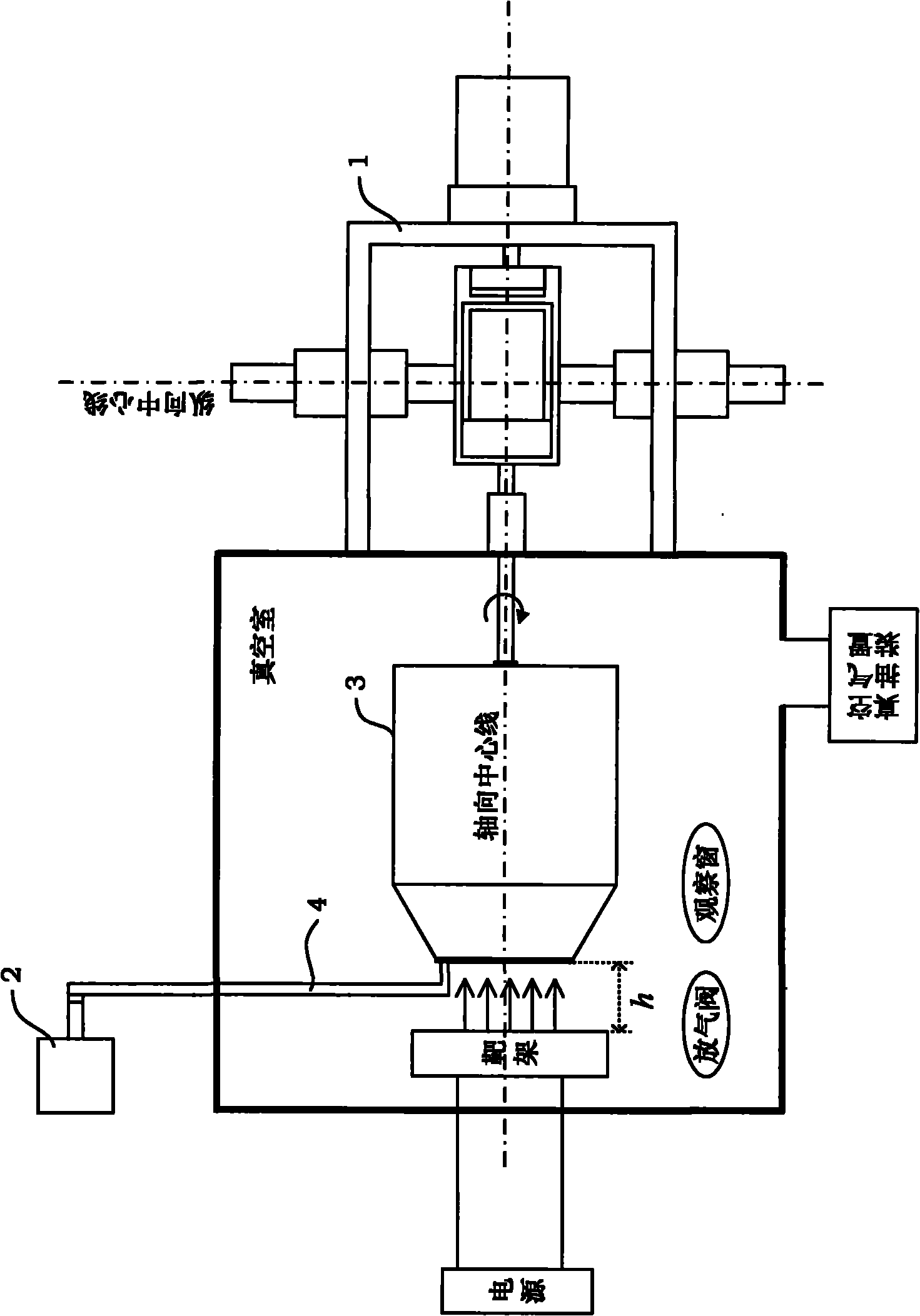

Drum-type sample stage and method for magnetron sputtering coating on powder particles by using same

A sample table and drum type technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of small particle size, uniform dispersion of powder particles, large specific surface area, etc., and achieve compactness High, strong adhesion, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

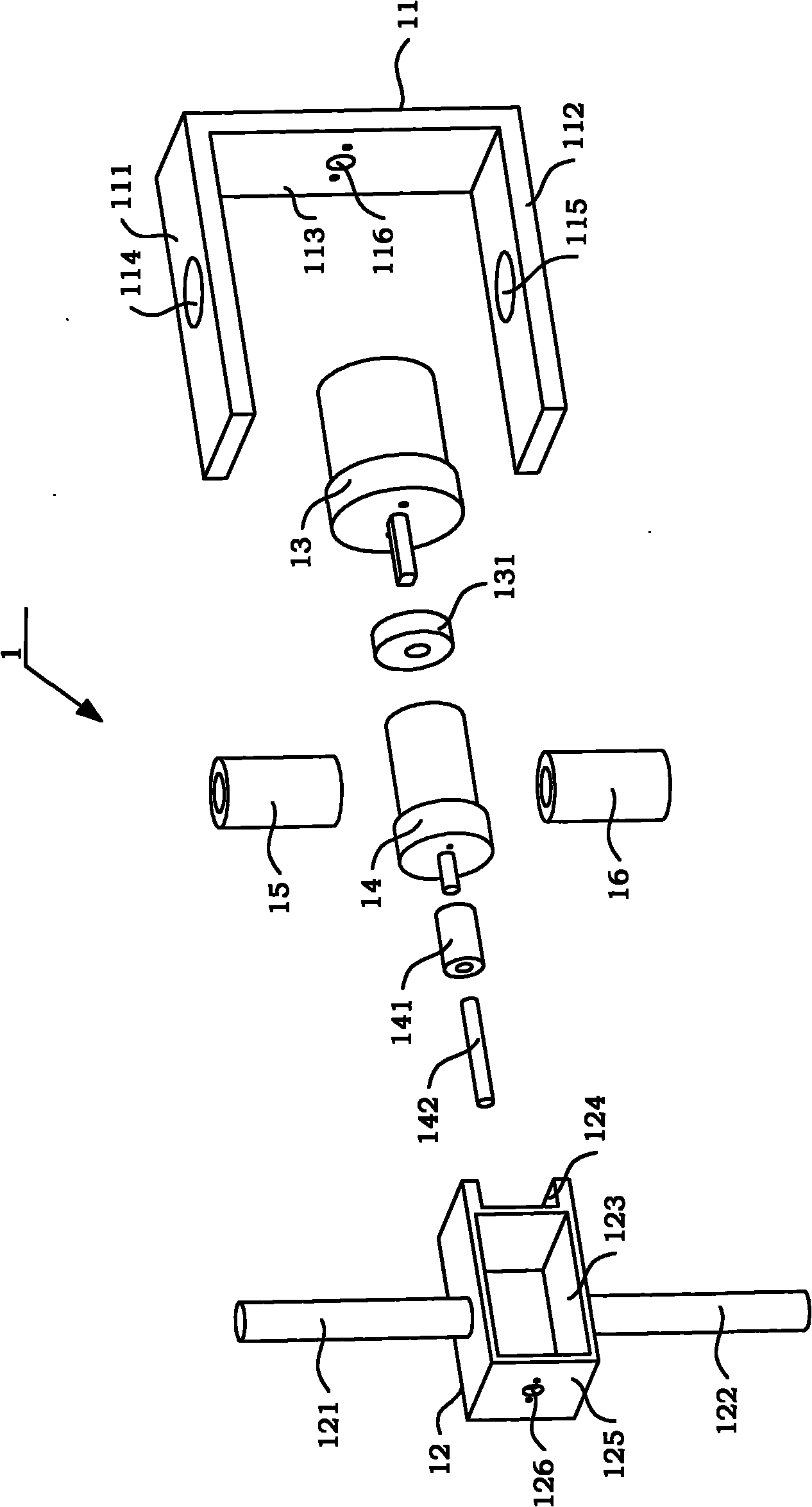

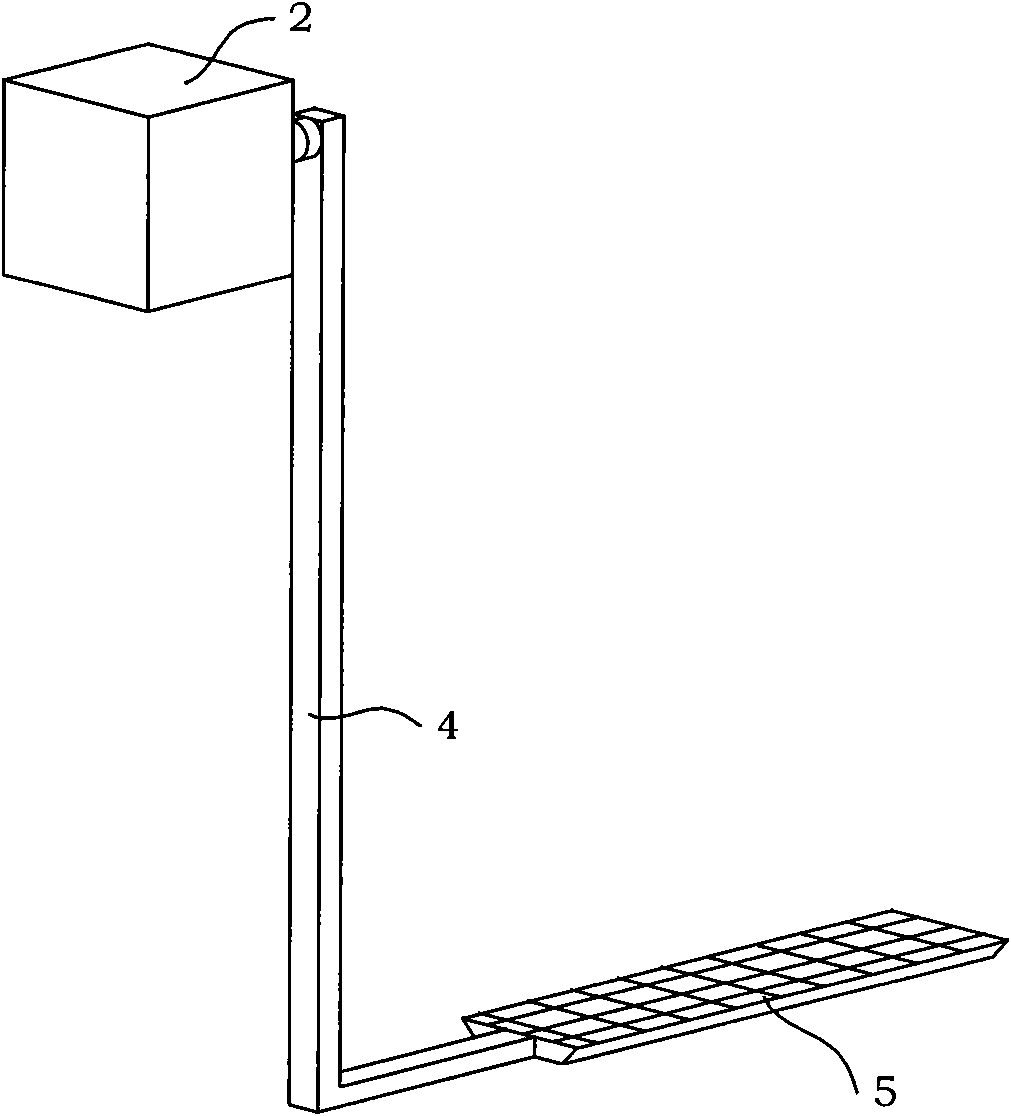

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1, with magnetron sputtering nickel-silver alloy film on the surface of inorganic hollow microsphere particles (fly ash) as an example, the detailed process steps are as follows:

[0068] (A) Open the vacuum chamber and put the powder particles into the drum 3;

[0069] (B) two sputtering targets of metallic nickel and metallic silver are respectively installed on different sputtering target holders;

[0070] (C) close the vacuum chamber, open the mechanical pump in the vacuum pumping device, and evacuate the vacuum chamber to 2Pa;

[0071] Turn on the molecular pump in the vacuum pumping device, and evacuate the vacuum chamber to 3.0×10 -3 Pa;

[0072] (D) Fill the vacuum chamber with argon gas, control its flow rate with a mass flow meter and keep it at 24 sccm, and keep the working pressure of the vacuum chamber at 0.8Pa during deposition;

[0073] (E) adjusting the output power of the vibration motor 13 up and down is 100W;

[0074] Adjusting the rota...

Embodiment 2

[0084] Embodiment 2, taking the magnetron sputtering nickel plating film on the surface of SiC particles as an embodiment, the detailed process steps are as follows:

[0085] (A) Open the vacuum chamber and put the powder particles into the drum 3;

[0086] (B) metal nickel target material is installed on the sputtering target frame;

[0087] (C) Close the vacuum chamber, turn on the mechanical pump in the vacuum pumping device, and evacuate the vacuum chamber to 3.3 Pa; turn on the molecular pump in the vacuum pumping device, and pump the vacuum chamber to 3.3 × 10 -3 Pa;

[0088] (D) Fill the vacuum chamber with argon gas, control its flow rate with a mass flow meter to maintain 30 sccm, and keep the working pressure of the vacuum chamber at 0.9Pa during deposition;

[0089] (E) adjusting the output power of the vibration motor 13 up and down is 80W;

[0090] Regulate the rotation speed that the circular rotation motor 14 provides to the drum to be 15r / min;

[0091] Adju...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap