Water drainage and gas production simulated experimental device

A simulation experimental device, drainage and gas production technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of simulation, cannot be adjusted continuously, and is not suitable for experimental simulation of water-producing gas wells, and achieves convenient movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

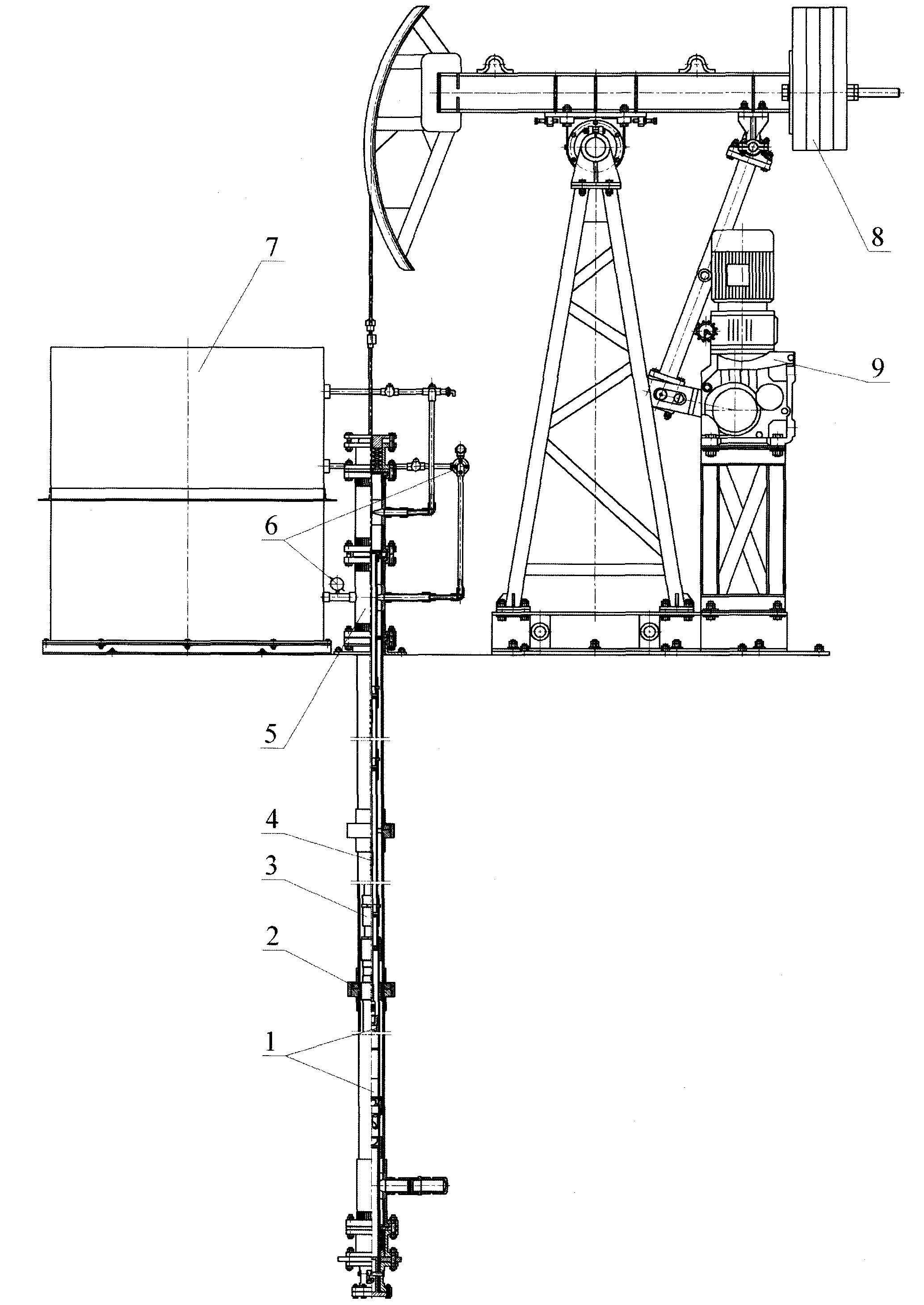

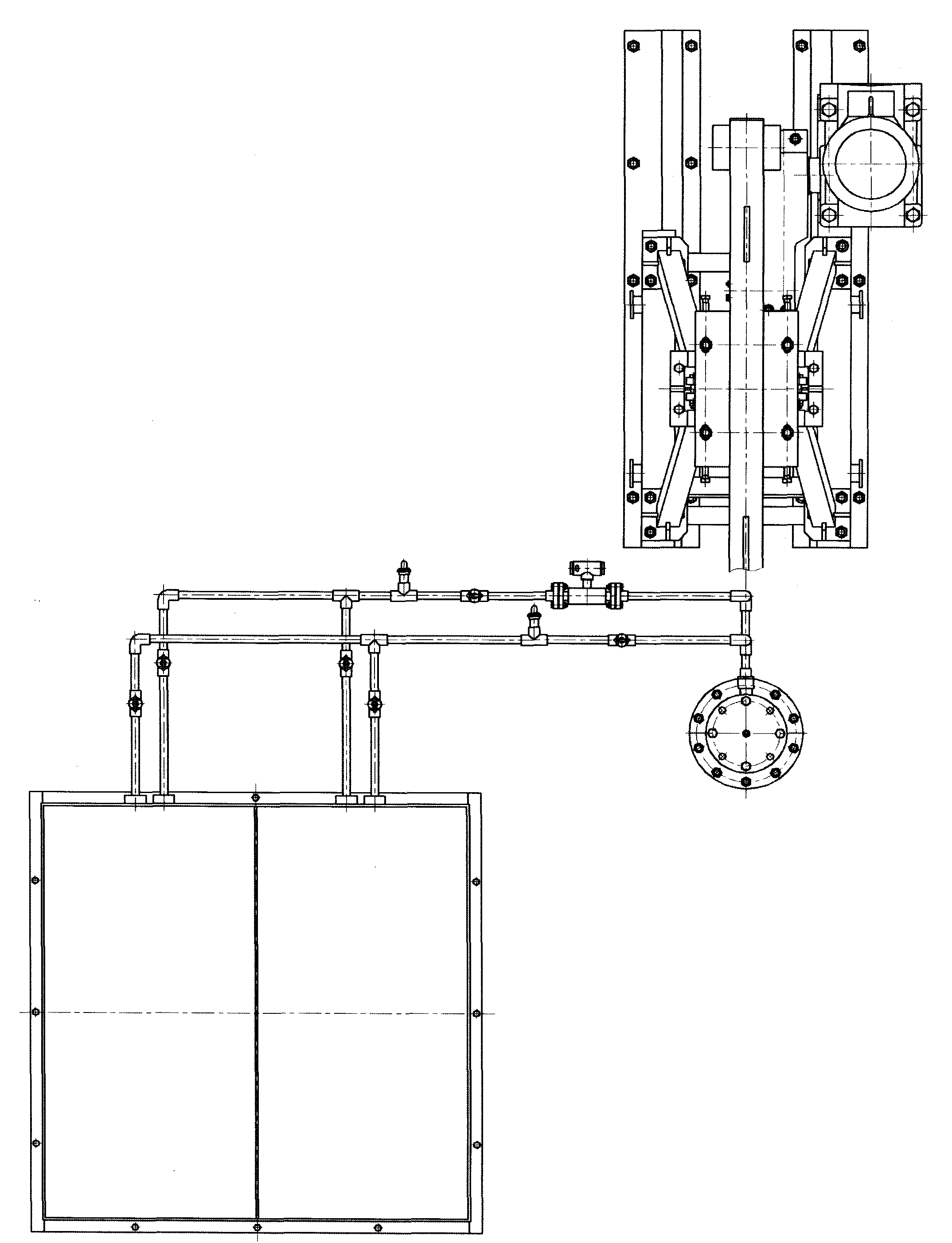

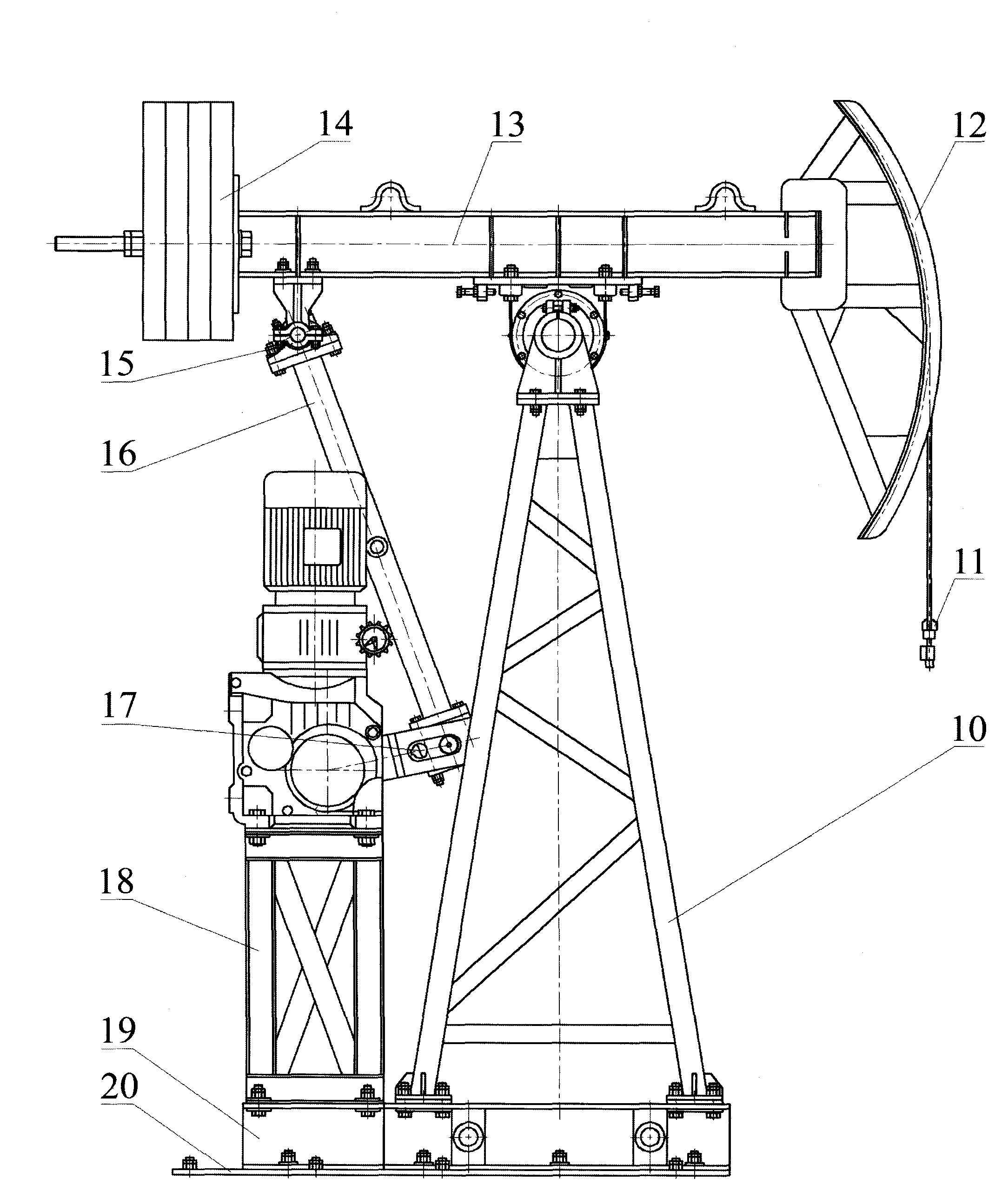

[0022] exist figure 1 In the process, the pump barrel of the drainage pump 1 is lowered below the dynamic liquid level in the well with the water pipe string 3, the plunger is lowered into the pump barrel from the water pipe string with the drainage rod string 4, and the water pipe string is lowered into the casing string 2. , to form a water jacket annular space, which is used to simulate gas-water two-phase flow for gas production, and the drainage rod string is lowered from the water pipe string to form a rod pipe annular space, which is used to transport well fluid, and the polished rod at the upper end of the drainage rod string The wellhead device 5 is suspended on the donkey head of the water pump 8, and the rotary motion of the reducer 9 is changed into the reciprocating motion of the suspension point by means of the four-bar linkage mechanism of the water pump. The power is transmitted from the ground to the downhole through the drainage rod 4, and the plunger of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com